Damping high-speed single phase brushless motor

A single-phase brushless motor, high-speed technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of motor temperature rise, large vibration, low operating efficiency, etc., achieve low vibration rate of products and improve service life , Fast installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

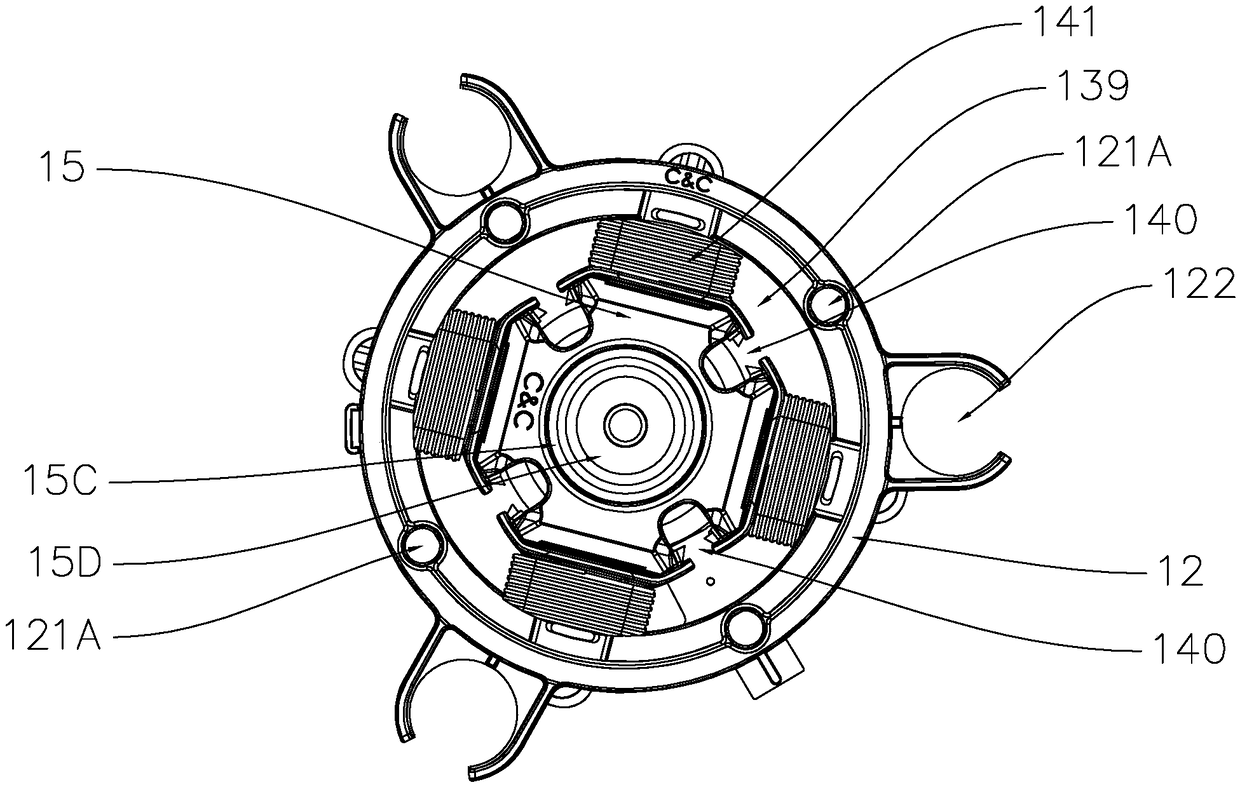

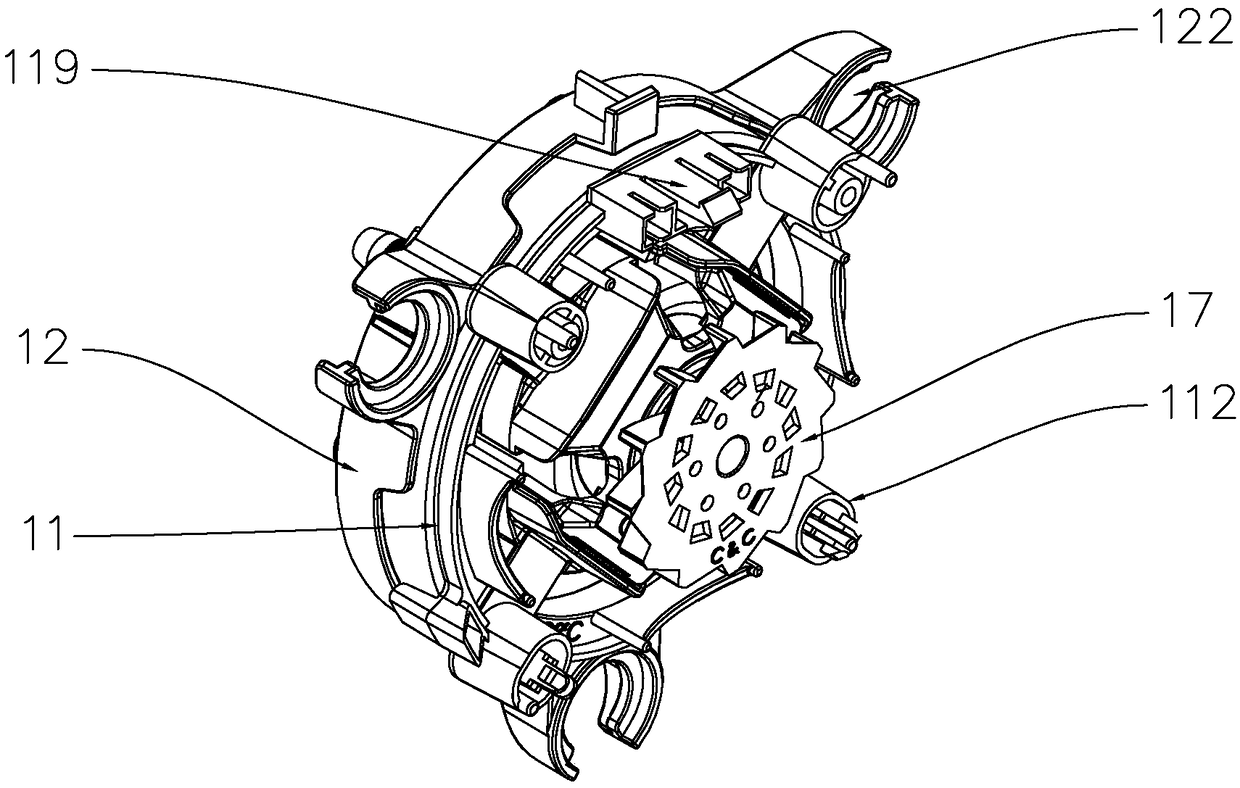

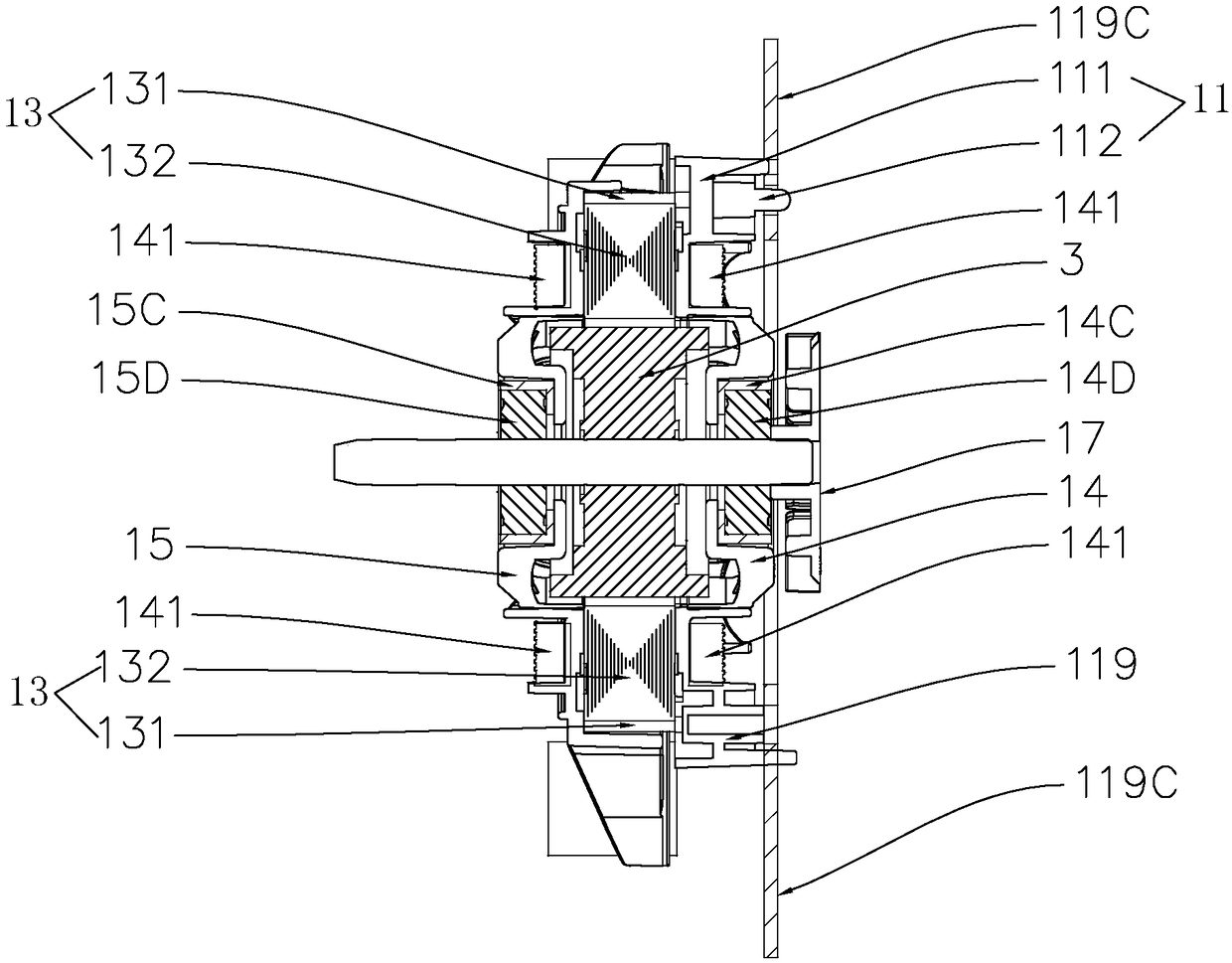

[0033] A vibration-damping high-speed single-phase brushless motor, the vibration-damping high-speed single-phase brushless motor includes an insulated wire frame 1, a stator ring 13, and a rotor 3;

[0034] The insulated wire frame 1 includes an upper frame 11 and a lower frame 12;

[0035] The upper frame 11 includes an upper frame stator fixing ring 111 and three circuit board fixing columns 112, the three circuit board fixing columns 112 are connected and fixed with the edge of the upper frame stator fixing ring 111, and the three circuit board fixing columns 112 are upward; The middle of the sub-fixed ring 111 is provided with an upper frame stator arrangement hole 113, and the ring body is provided with four upper frame fan-shaped copper coil winding through holes 114, and the hole edge on the opposite side of each upper frame fan-shaped copper coil winding through hole is uniform. The upper frame fan-shaped hole extends axially along the side plate 115; the inner edge b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com