Water injection well bisalt anti-scaling descaling device

An acid salt, water injection well technology, applied in wellbore/well parts, cleaning equipment, production fluids, etc., can solve the problems of short anti-scaling and descaling time, increase oil refining costs, poor injection effect, etc., to avoid frequent The effect of shutting down the well, reducing operating costs, and long-term anti-scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

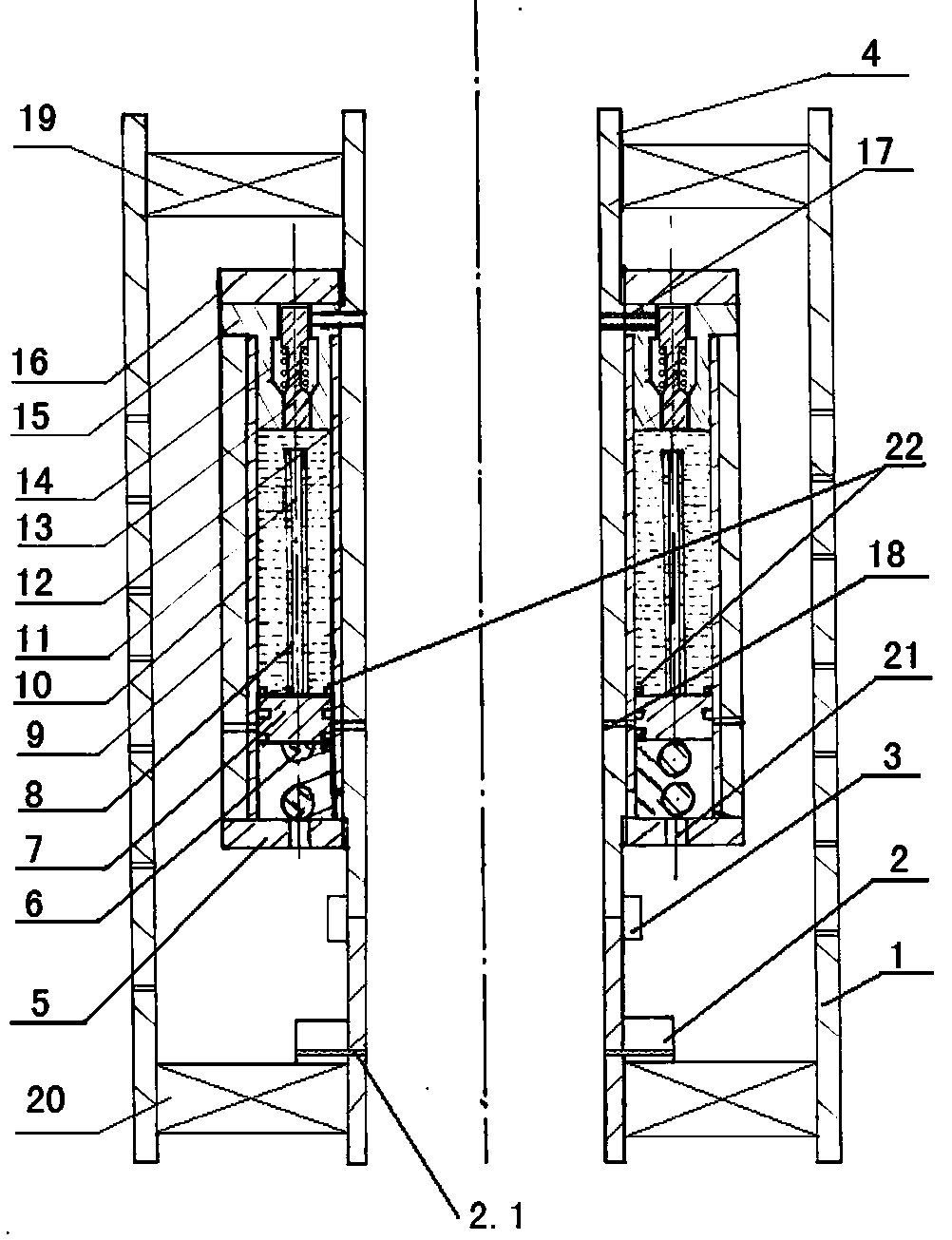

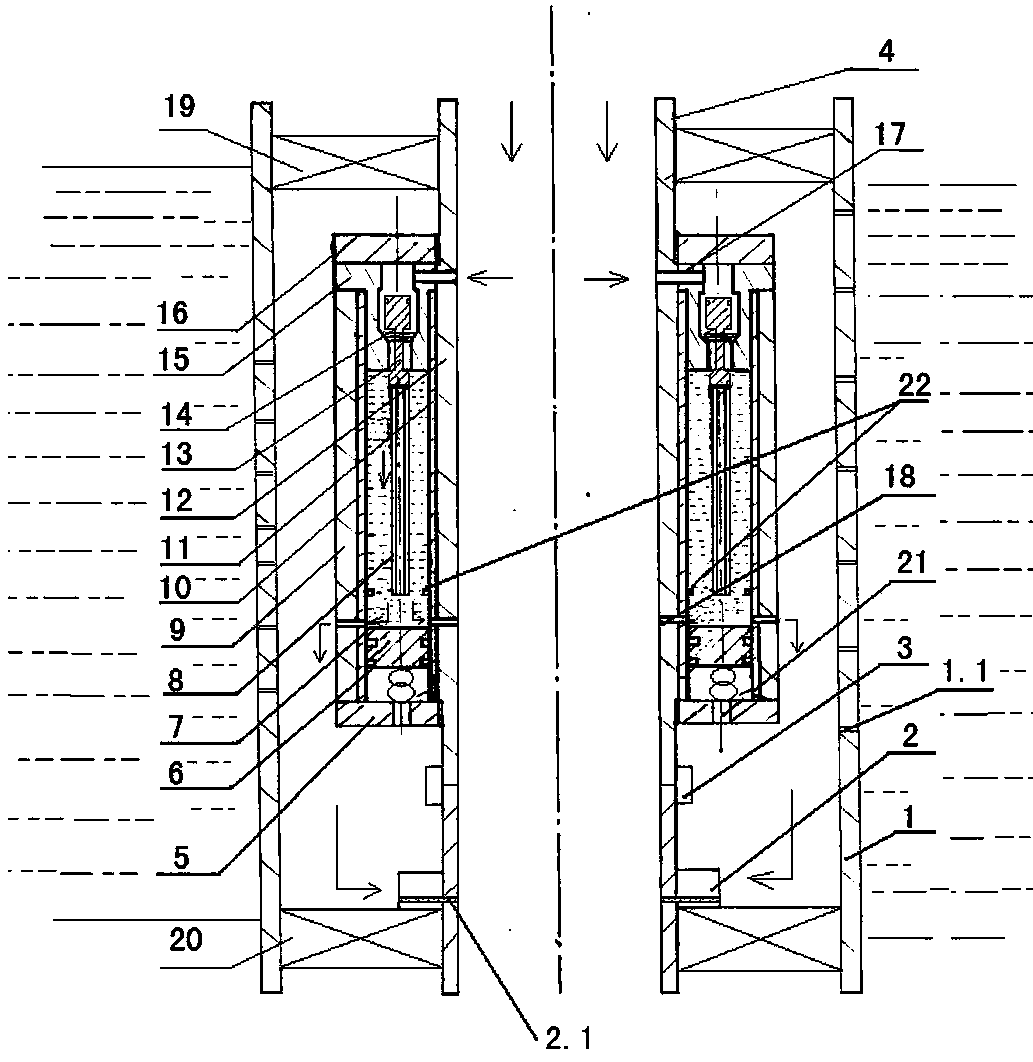

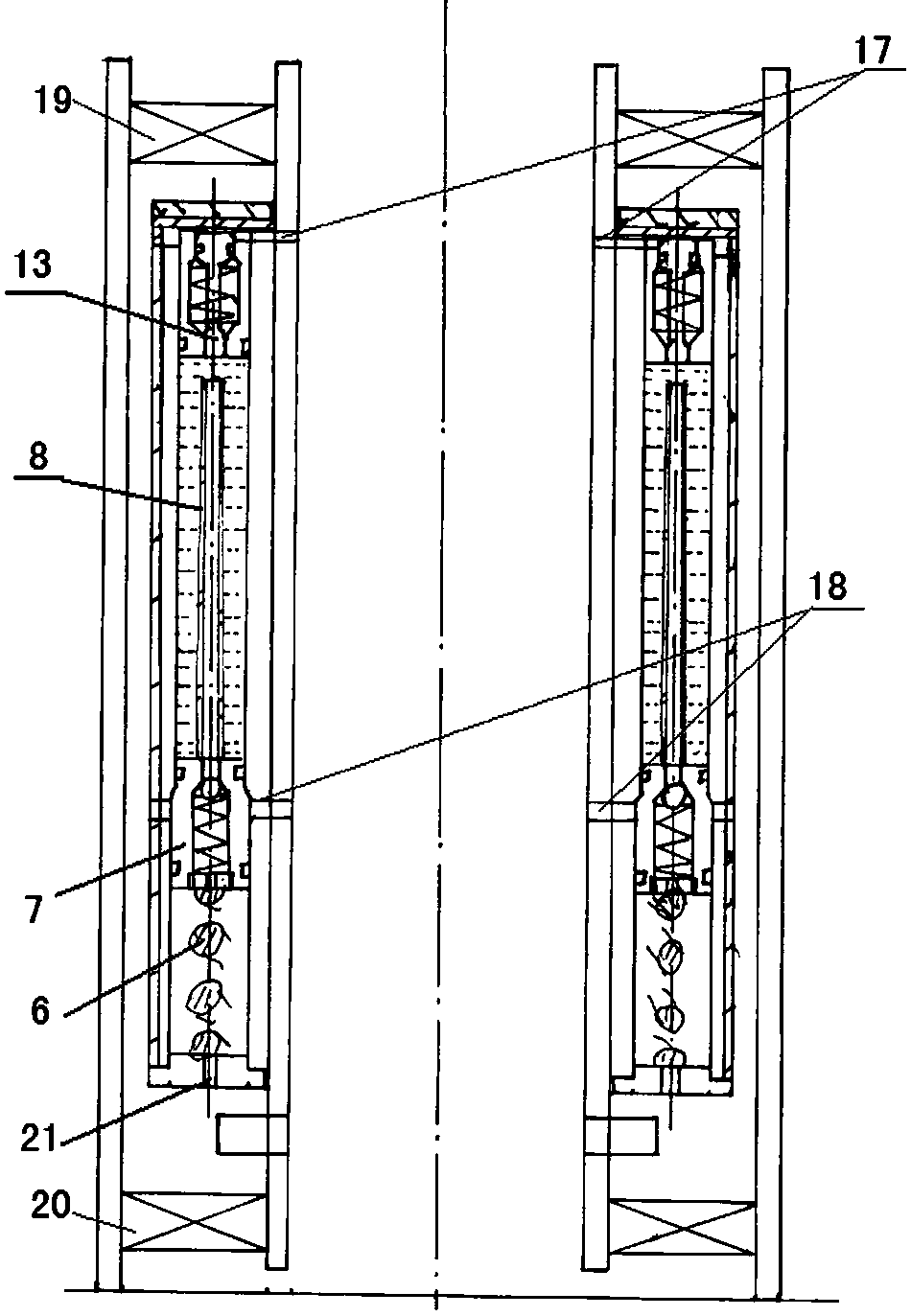

[0025] Embodiment 1, a kind of water injection well acid salt anti-scaling and descaling device mentioned in the present invention, refer to the attached Figure 1-2 , the technical solution is: including the lower stop ring 5, the closing spring 6, the liquid outlet piston 7, the pressure transmission capillary 8, the protective sleeve 9, the outer tube 10 of the container, the inner tube 11 of the container, the center tube 12, the opening piston 13, and the return spring 14. Container gland 15, upper retaining ring 16, liquid outlet opening pipe 17 and liquid outlet pipe 18, the annular cavity formed by the container outer pipe 10 and the container inner pipe 11, the container inner pipe 11 is set on the outer wall of the central pipe 12 , powdered ammonium chloride solid is housed in the annular cavity, a lower retaining ring 5 is provided at the bottom of the annular cavity, and the upper side of the lower retaining ring 5 is connected to the liquid outlet piston 7 through...

Embodiment 2

[0043] Embodiment 2, the present invention mentions a kind of acid salt anti-scaling and descaling device for water injection wells, powdered ammonium sulfate solid is housed in the annular cavity that container outer tube 10 and container inner tube 11 form, because ammonium sulfate meets water , also has weak acidity, and can also react to scales to achieve the purpose of scale removal and scale prevention. The method of use is the same as that of Example 1, and the dosage is adjusted according to the scaling situation of the water injection well.

Embodiment 3

[0044]Embodiment 3, the present invention mentions a kind of acid salt anti-scaling and descaling device of water injection well, in the annular cavity that container outer pipe 10 and container inner pipe 11 are formed, powdery ammonium nitrate solid is housed, because ammonium nitrate meets water after , also has weak acidity, can also react to the scale, and then achieve the purpose of descaling and anti-scaling. Its usage method is the same as that of Example 1, and the dosage is adjusted according to the fouling situation of the water injection well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com