Gas well leaking stoppage device and gas well drilling equipment

A gas well and drilling technology, which is applied in the field of gas well plugging devices and gas well drilling equipment, can solve the problems of difficult gas well leakage repair and repair, poor effect, etc., and achieve the elimination of the possibility of flash explosion accidents, simple structure and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

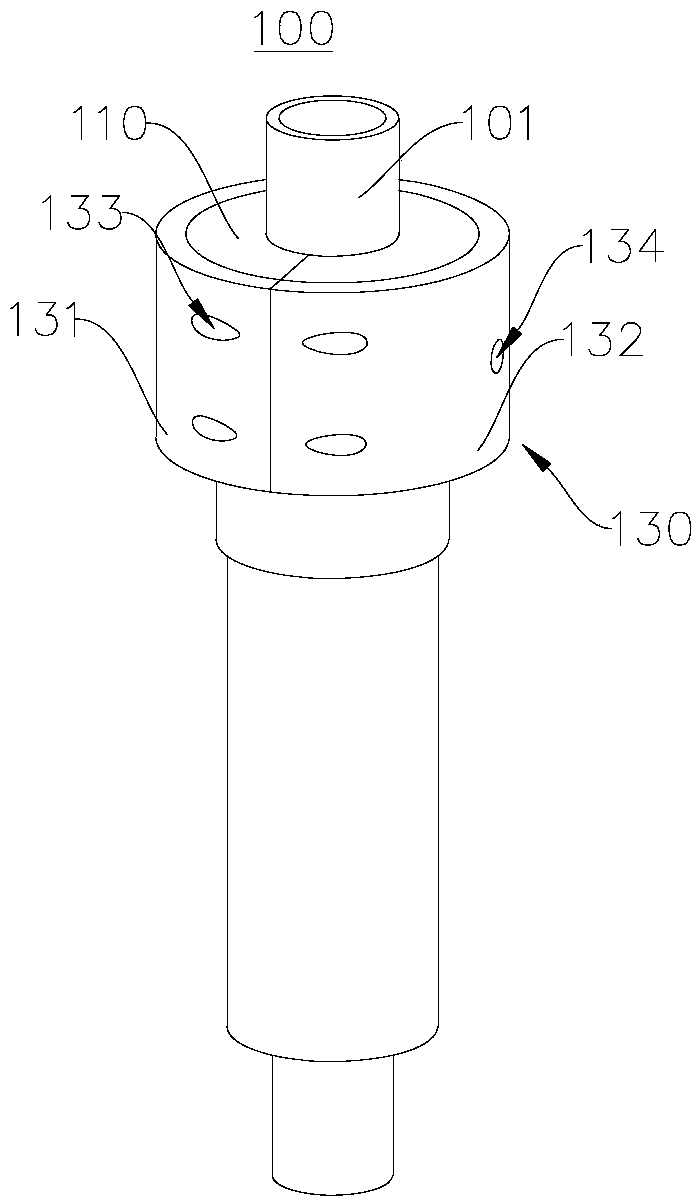

[0037] figure 1 shows a schematic structural view of the gas well plugging device 100 provided by the embodiment of the present invention, please refer to figure 1 . This embodiment provides a gas well plugging device 100, which is mainly used for leakage at the wellhead annular steel plate of a coalbed gas well. It can be understood that the application of the gas well plugging device 100 is not limited in the present invention.

[0038] In this embodiment, the gas well plugging device 100 includes a first snap ring 110, a second snap ring 120 and a third snap ring 130; the first snap ring 110, the second snap ring 120 and the third snap ring 130 are coaxial set up. The third snap ring 130 is sleeved on the outside of the first snap ring 110 and the second snap ring 120 .

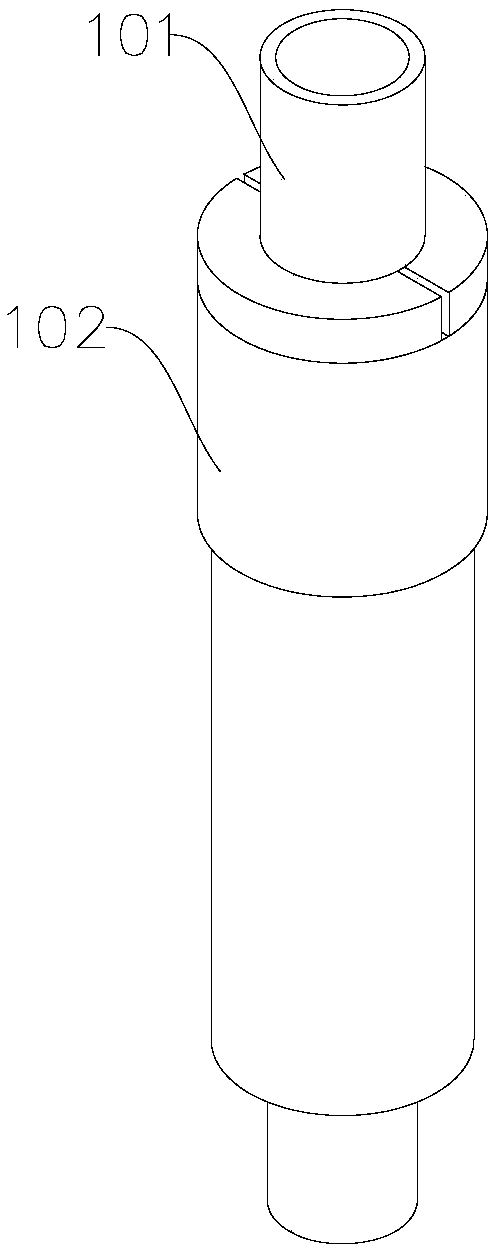

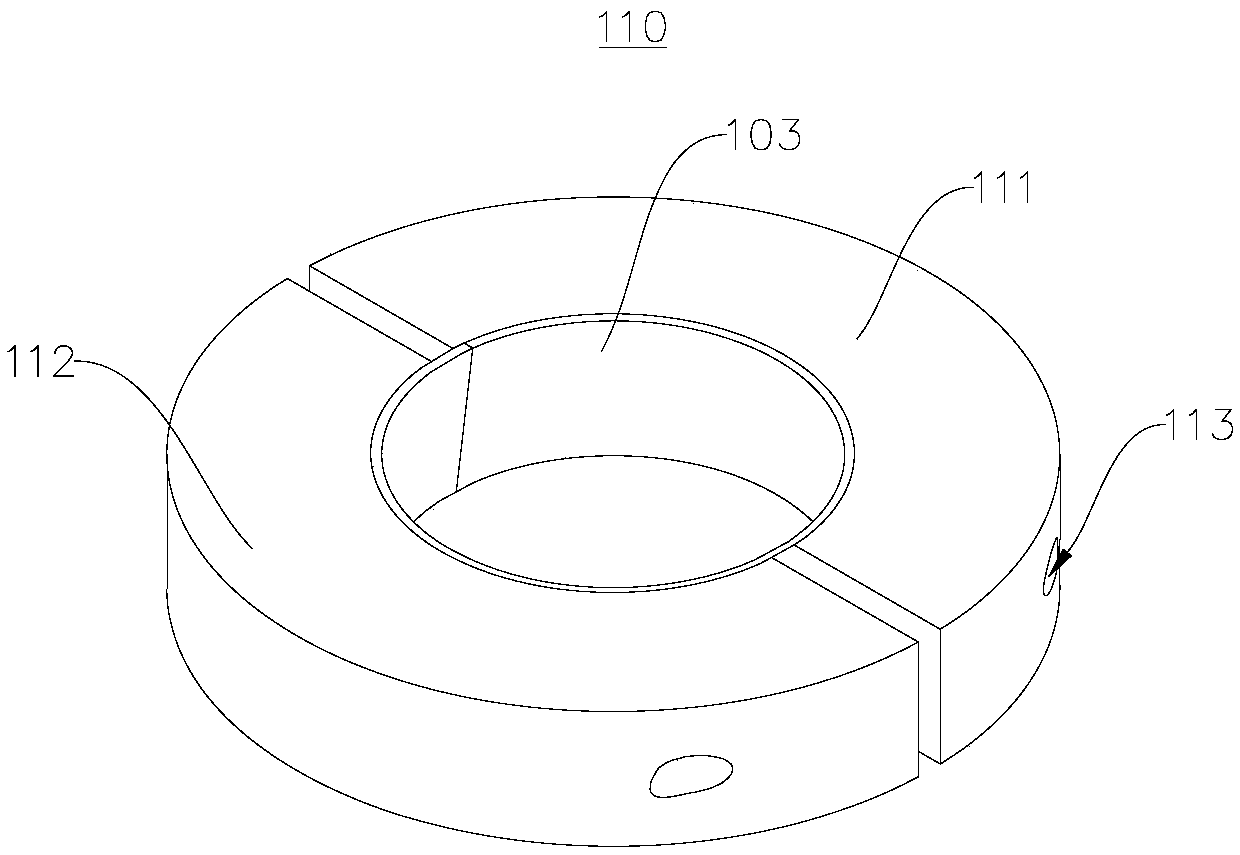

[0039] figure 2 A schematic diagram of the gas well gas production structure is shown, image 3 A schematic structural view of the first clasp 110 provided by the embodiment of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com