Convenient injection mold cleaning device

A cleaning device and injection mold technology, applied in the field of cleaning equipment, can solve the problems of inhaling too much cleaning agent, low efficiency of manual cleaning, waste of cleaning agent, etc., and achieve the effects of high efficiency, convenient lifting and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

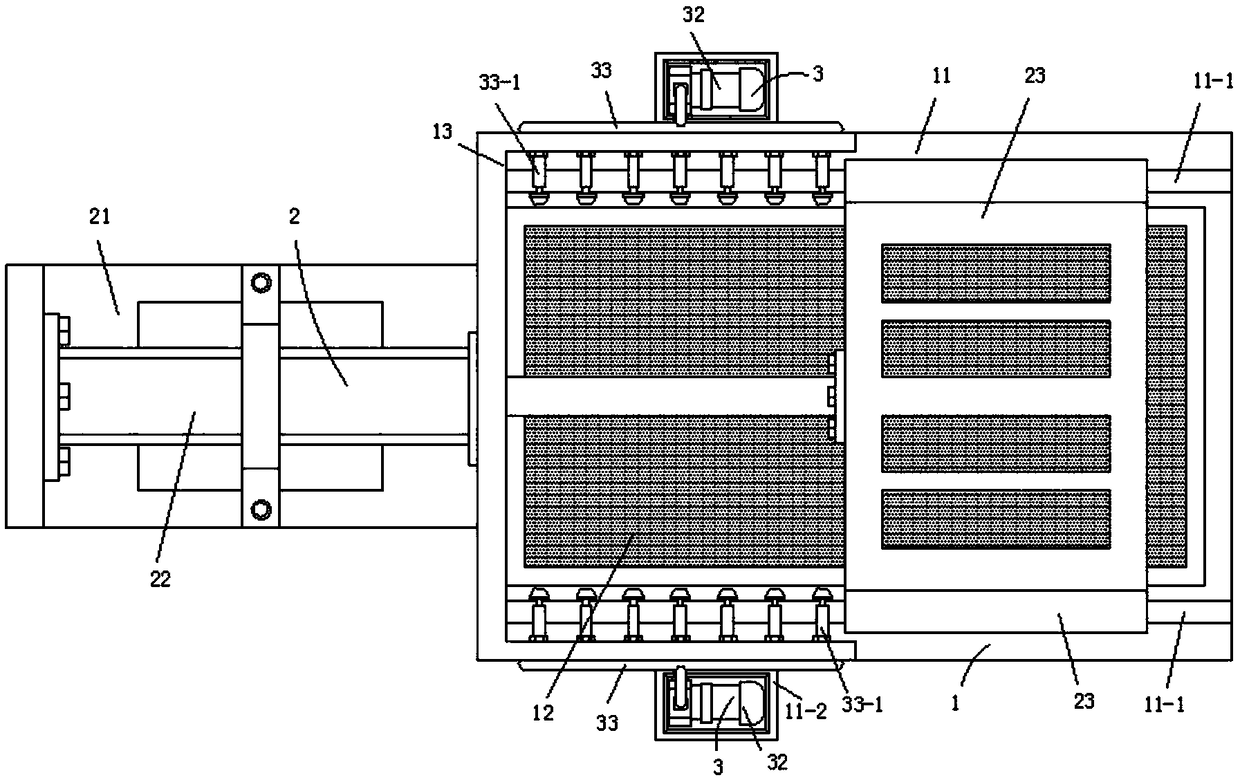

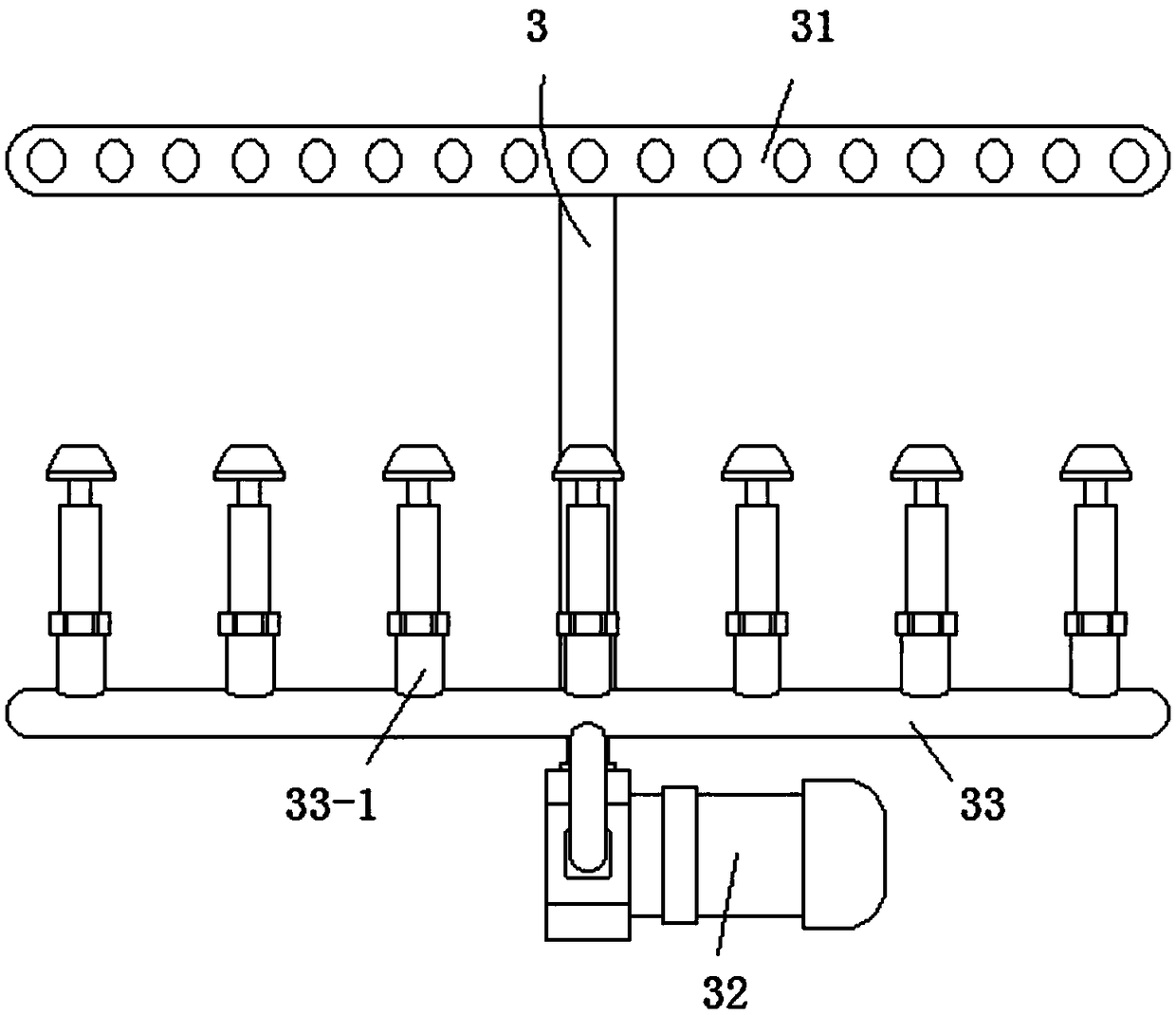

[0013] figure 1 with figure 2 A specific embodiment of the present invention is shown: a convenient cleaning device for injection molds, which is characterized in that it includes a cleaning machine table 1, a moving cleaning table mechanism 2 and a cleaning actuator 3, and the moving cleaning table mechanism 2 is controlled by a hydraulic cylinder fixing seat 21 , a hydraulic cylinder 22 and a sliding plate 23, the hydraulic cylinder fixing seat 21 is fixedly connected to the back wall of the cleaning machine 1, the hydraulic cylinder 22 is fixedly installed on the hydraulic cylinder fixing seat 21, and the side end of the sliding plate 23 It is fixedly connected with the output end of the hydraulic cylinder 22, and the sliding plate 23 is slidingly connected with the cleaning machine 1. There are two cleaning actuators 3, and the two cleaning actuators 3 are symmetrically distributed on the central axis of the cleaning machine 1. On both sides, the cleaning actuator 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com