Subsonic-speed jet type pneumatic probe calibration wind tunnel

A jet-type, subsonic technology, applied in aerodynamic tests, measuring devices, instruments, etc., can solve the problems of large area, high operating cost, large volume, etc., and achieve low operating cost, low cost, and land occupation The effect of area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

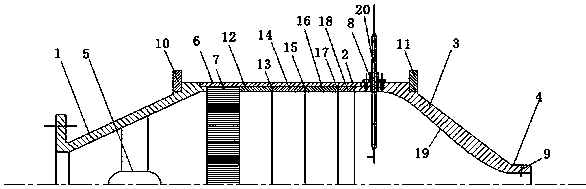

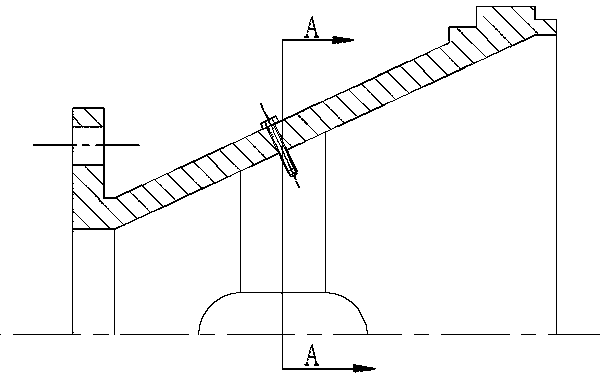

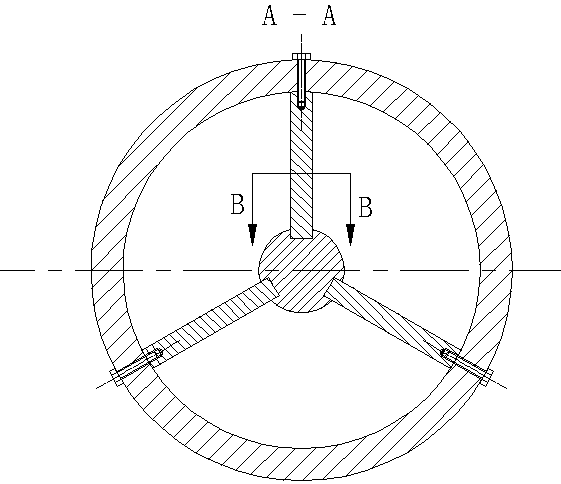

[0036] The subsonic jet type pneumatic probe calibration wind tunnel is characterized in that: it includes an inlet expansion section 1, a steady flow section 2, a contraction section 3 and an experimental section 4 connected in sequence; the inlet expansion section 1 gradually expands from the end to the steady flow section , the contraction section 3 gradually shrinks from the steady flow section 2 to the experimental section 4; the inlet diversion cone 5 is set on the inlet expansion section 1, and the steady flow section 2 includes an outer ring 6 arranged in sequence along the wind flow direction, The honeycomb 7 and a number of inner rings and broken vortex nets arranged at intervals; the total pressure probe mounting seat 8 is arranged on the contraction section 3 close to the flow stabilization section 2, and the static pressure hole is arranged on the contraction section 3 away from the flow stabilization section 2 9.

[0037] Further, the inlet expansion section 1 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com