Pile head breaking and cutting device for bridge cast-in-place pile and using method

A cast-in-place pile and pile head technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of difficulty in removal, high cost and high structural strength, and achieve the goal of reducing cost, reducing concrete thickness and improving construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

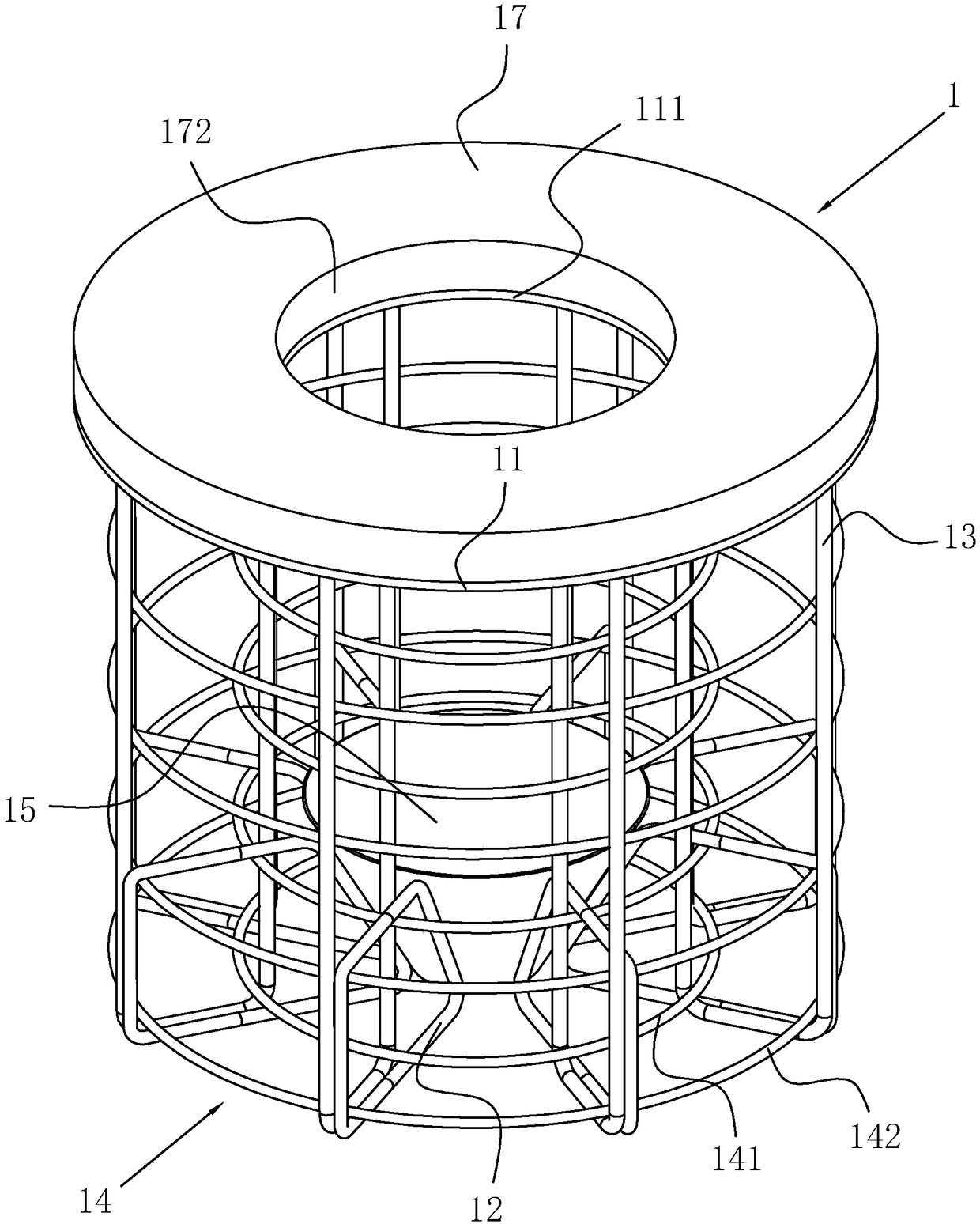

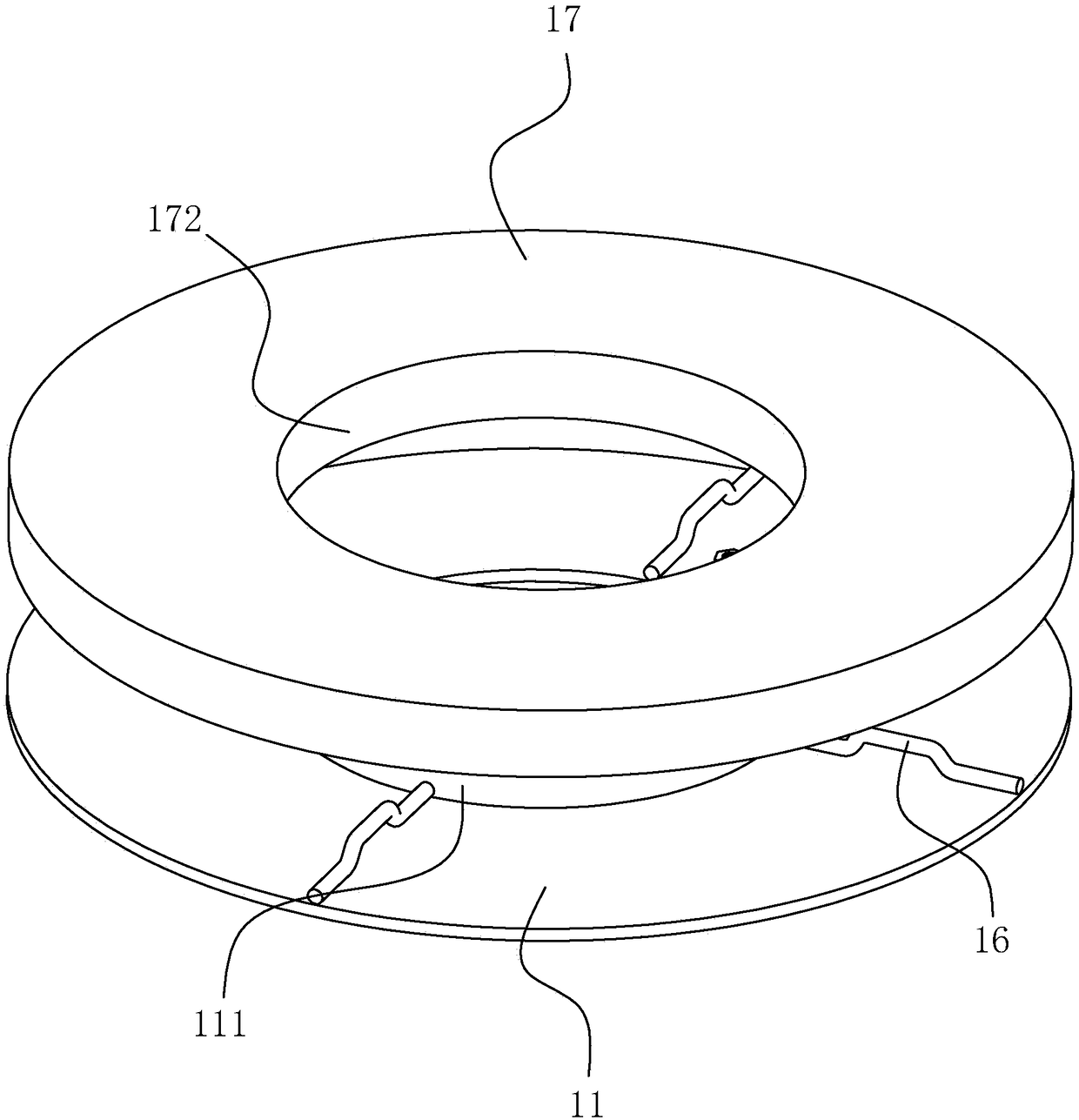

[0043] A pile head breaking and shearing device for cast-in-situ bridge piles, such as figure 1As shown, the shearer body 1 is included. Here, the size of the shearer body 1 is determined according to the diameter of the cast-in-situ pile and the designed pile head length, and the shearer body 1 includes a cover plate 11 arranged in a disc shape. 11 has a relief hole 111 in the center, and a plurality of vertically arranged crushing ribs 12 are arranged at intervals around the axis of the cover plate 11 at the bottom of the cover plate 11. Here, the crushing ribs 12 are arranged in a frame structure.

[0044] Generally, the actual pouring length of the cast-in-place pile is greater than the calculated length setting, so that the sediment at the bottom of the pile and the impurities precipitated in the mud during the pouring process gradually gather to the top of the cast-in-place pile to form a certain thickness of laitance, so that after the pile head is removed, the cast-in-s...

Embodiment 2

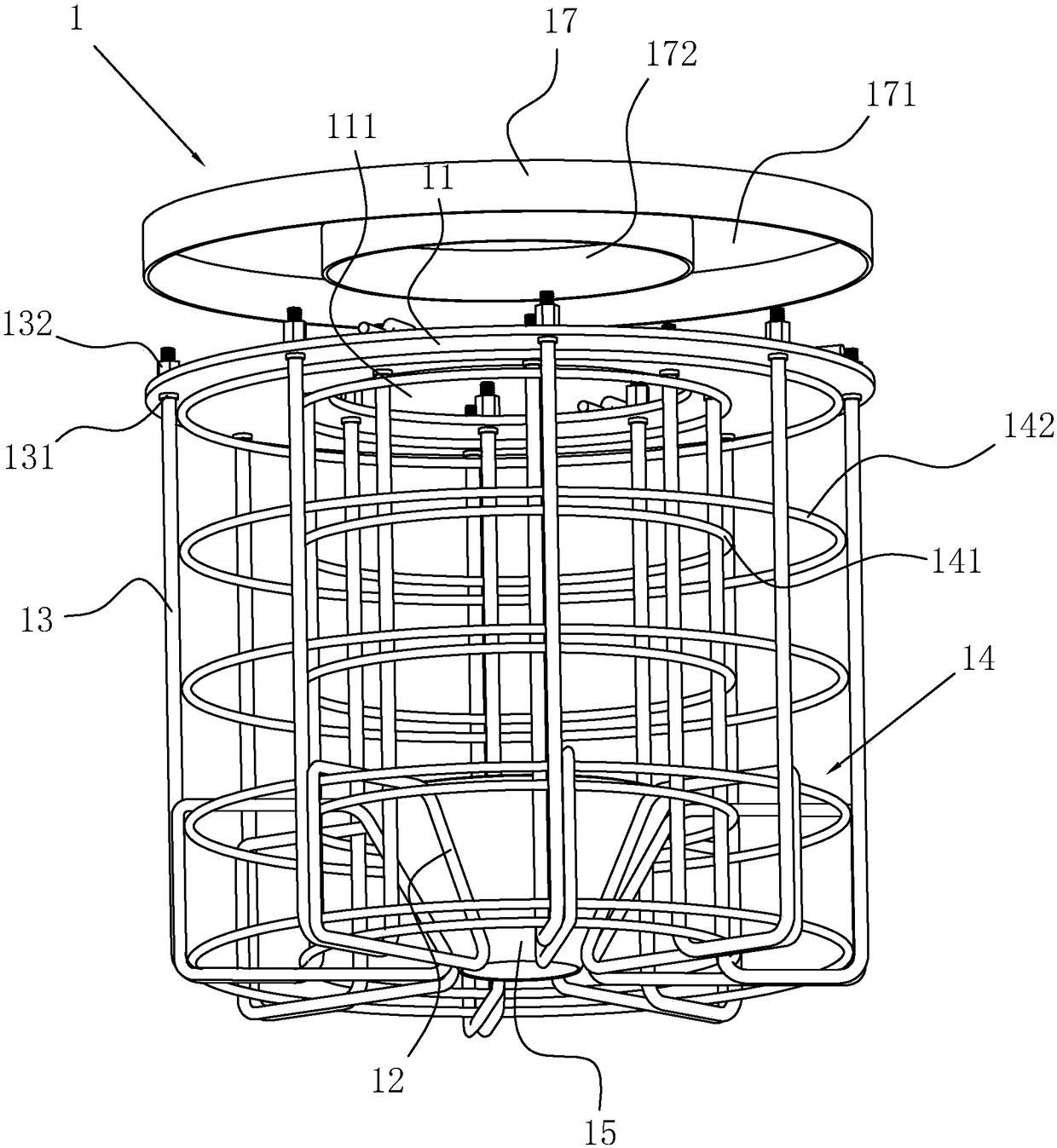

[0061] This embodiment is substantially the same as Embodiment 1, the difference is that in order to further stabilize the structure of the shearer body 1, as figure 2 As shown, the broken tendons 12 are sleeved on two groups of reinforcing hoops 14 at the bottom of the high-strength U-shaped bolts 13, and the radius of the first reinforcing hoop 141 is equal to the radius of the cylinder surrounded by a plurality of high-strength U-shaped bolts 13. The second reinforced The radius of the hoop 142 is equal to the radius of the cylinder surrounded by a plurality of high-strength U-shaped bolts 13 outside. In this way, on the one hand, the forced deformation of the first reinforcement hoop 141 and the second reinforcement hoop 142 and the high-strength U-shaped bolt 13 is used to realize the socket connection of the reinforcement hoop group 14; Outside the two sets of reinforcing hoops 14 at the bottom of the body 1, the reinforcing hoops 14 are used to locate the position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com