Production method of superfine fiber synthetic leather with antistatic and electrically conductive properties

A technology of ultra-fine fibers and production methods, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as inconvenience in life and work, static electricity cannot be safely released, and achieve the effect of simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

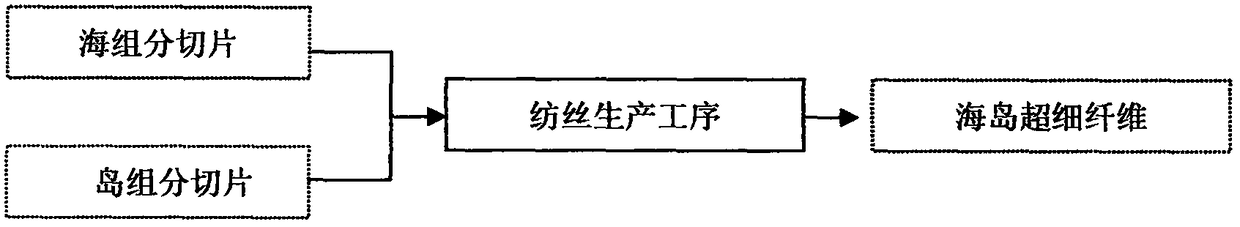

[0017] figure 1 Schematic diagram of the processing flow for island microfiber

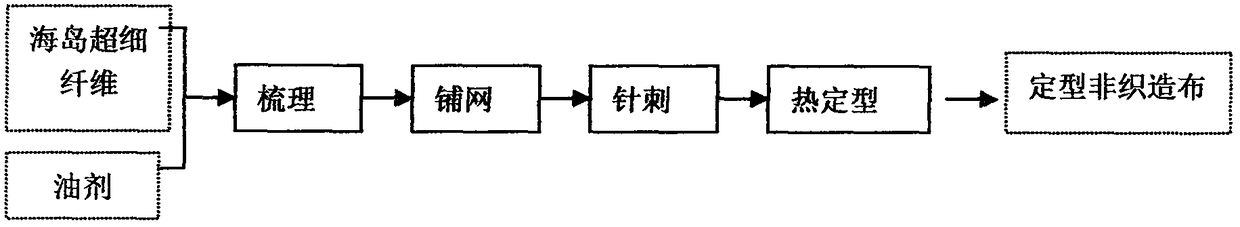

[0018] figure 2 Schematic diagram of the production process for sizing nonwovens

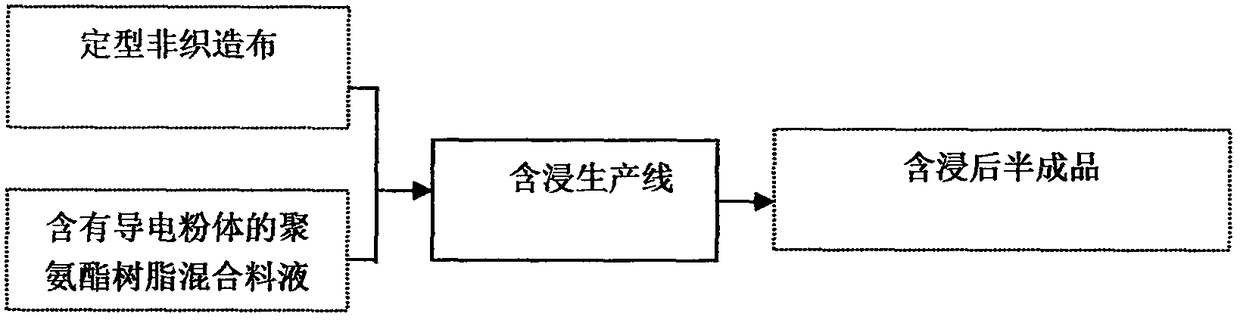

[0019] image 3 Schematic flow chart of wet slurry impregnation treatment for conductive particles

[0020] Figure 4 Schematic flow chart for the dissolution of sea components for the sea-island microfiber alkali reduction method

[0021] Figure 5 Schematic diagram of the process for the manufacture of antistatic conductive microfiber synthetic leather products

[0022] As a specific implementation example, a production method of superfine fiber synthetic leather with antistatic and conductive properties is realized through the following steps:

[0023] 1) Island microfiber processing

[0024] Firstly, the raw materials of sea component chips (such as polyethylene) and island component chips (such as nylon chips) are made into sea-island superfine fibers through the spinning production process; the spinni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com