Rotating mechanism with automatic barrel installing, automatic barrel cover covering and automatic empty barrel replacing

A technology of automatic replacement and rotation mechanism, applied in the direction of packaging, transportation and packaging, packaging item type, etc., to achieve cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

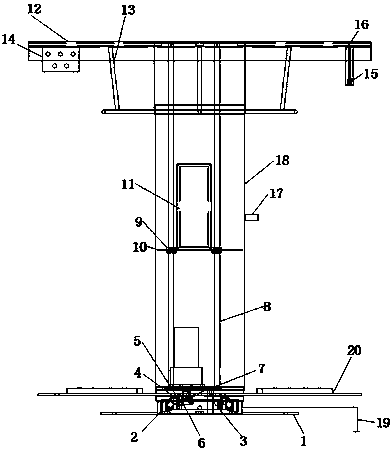

[0013] refer to figure 1 , the specific implementation method adopts the following technical solutions: a rotating mechanism for automatically loading barrels, automatically covering barrels, and automatically replacing empty barrels, including a bottom frame 1, a slewing support 2, a support shaft 3, a motor mounting plate 4, and a motor flange Backing plate 5, gear 6, gear reduction motor 7, support column 8, fixed ring 9, waterproof support column 10, electric control box 11, waterproof ceiling 12, first cover drop device 13, manual switch control box 14, photoelectric sensor 15 , photoelectric sensor fixing frame 16, second cover drop device 17, shield 18, power cord 19 and rotating platform 20, gear reduction motor 7 and chassis 1 through sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com