Film blowing and printing all-in-one machine

An all-in-one machine and printing unit technology, used in printing machines, rotary printing machines, printing and other directions, can solve the problems of affecting production operation, slow production speed, poor effect, etc., achieve rapid and sufficient cooling, improve production speed, and avoid a large number of The effect of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be introduced and explained in detail below in conjunction with accompanying drawing by specific embodiment:

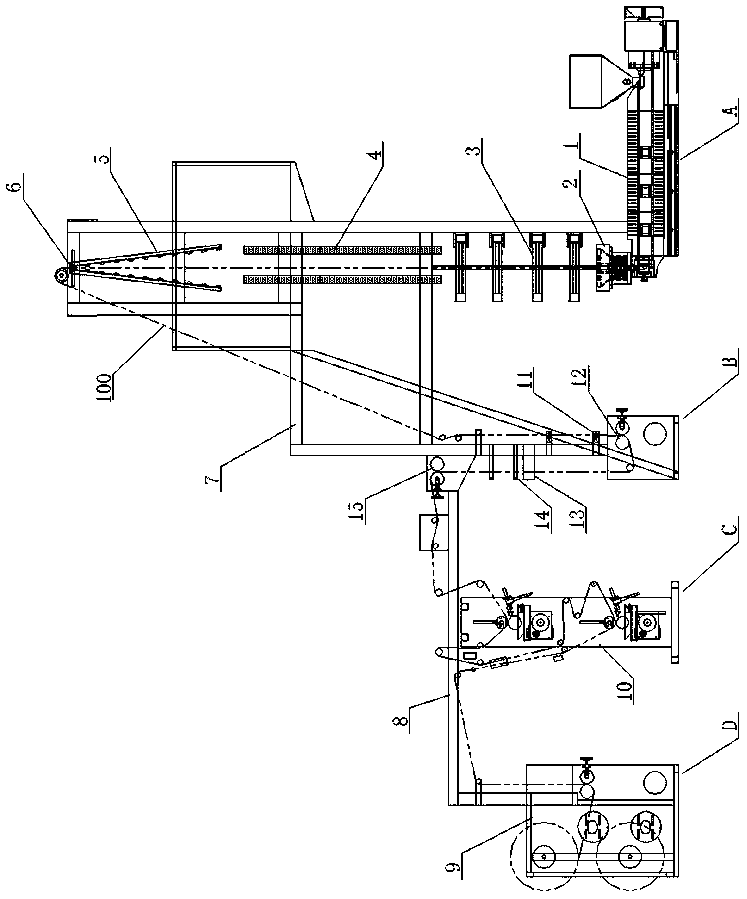

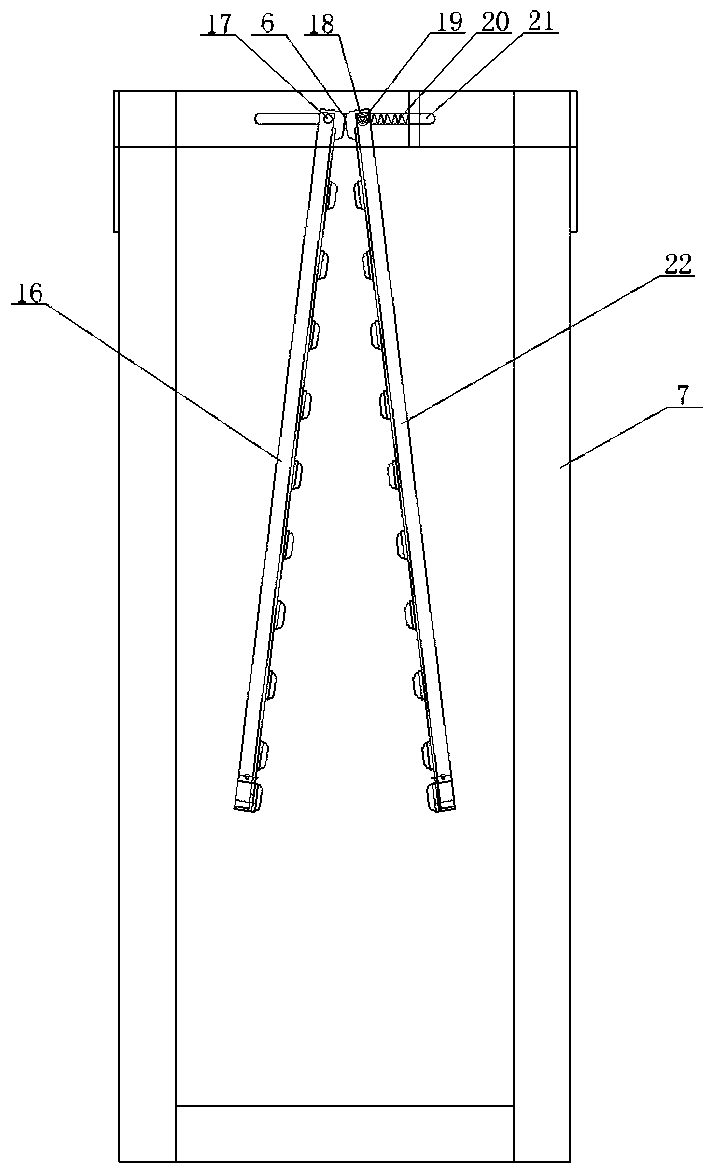

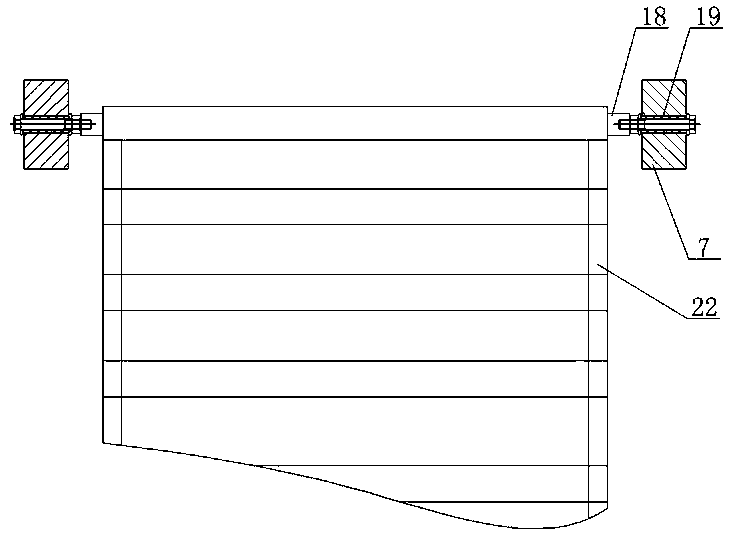

[0019] As shown in the figure, the film blowing and printing all-in-one machine of the present invention is composed of a winding part D arranged in the left and right directions, a two-color printing part C, a traction part B and a film blowing main machine part A, and the film blowing main machine part A includes a film blowing main machine 1 and the forming mold 2 connected to the outlet of the film blowing main machine, the blowing film main machine 1 blows out the self-sealing film bag 100 tube material with zipper through the forming mold 2, and the top of the forming mold 2 is provided with a cooling air ring 3 and a stainless steel cooling air pipe 4 With the herringbone frame 5, the cooling air ring 3 is provided with four floors up and down, and the cooling air ring 3, the stainless steel cooling air duct 4 and the herringbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com