Rapid-cooling plastic mold for water tank cover

A plastic mold and rapid cooling technology, applied in the field of molds, can solve the problems that the cooling equipment cannot be cooled in place, reduce labor efficiency, and high mold temperature, and achieve the effects of rapid and sufficient cooling, saving cooling time, and rapid cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

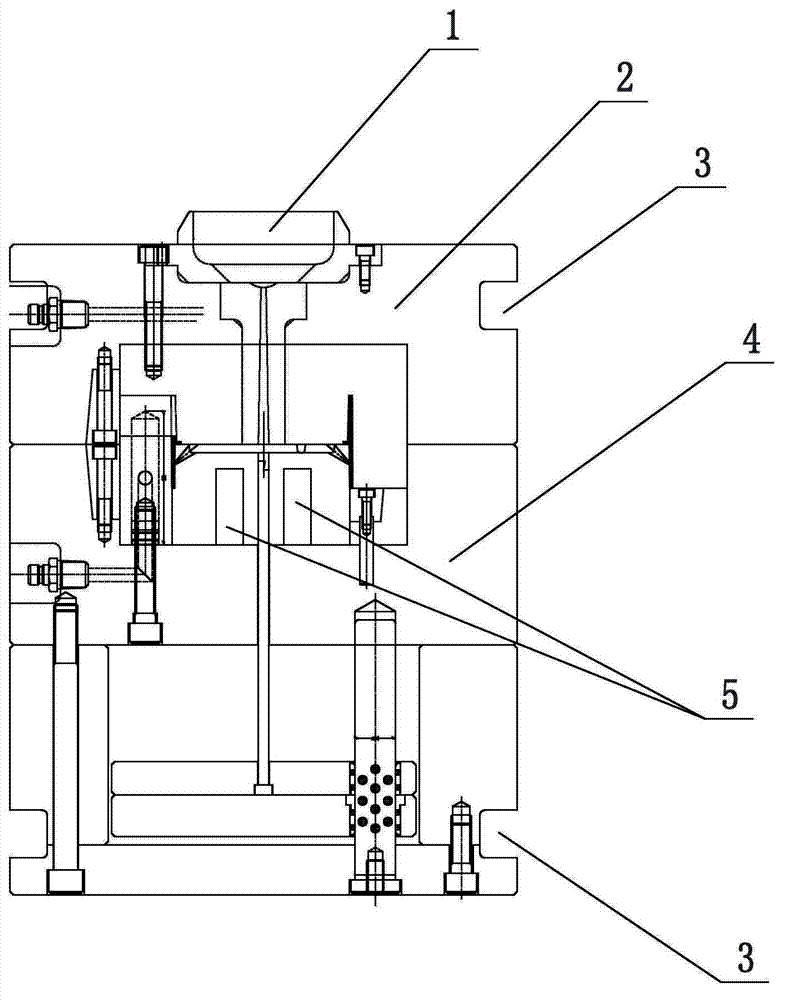

[0015] Such as figure 1 As shown, a plastic mold for rapid cooling water tank cover includes a mold body 4 on which a mold base 2 is arranged. The upper part of the mold base 2 is provided with a positioning ring 1, and the middle part of the mold body 4 is provided with a water cooling device.

[0016] In this embodiment, the water cooling device includes a water inlet and a water outlet, and the water inlet and the water outlet are connected through pipelines, and several well-shaped cooling pipes 5 are connected to the pipelines. Usually, the number of well-shaped cooling pipes is determined by actual needs, generally two.

[0017] In this embodiment, chamfers with an angle of 30° are provided on both sides of the upper end of the positioning ring 1 . A groove 3 is respectively arranged on the four corners of the mold base, and the depth of the groove 3 is 20cm.

[0018] A plurality of water well-shaped cooling pipes are arranged in the middle of the mold body, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com