On-line deactivated catalyst regenerating method and on-line deactivated catalyst regenerating device for wood tar hydrogenation in fluidized bed

A deactivated catalyst and wood tar technology, which is applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of non-continuous operation, environmental hazards, oil waste, etc., and achieve continuous operation of the device Operation, avoid operation cycle, high extraction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

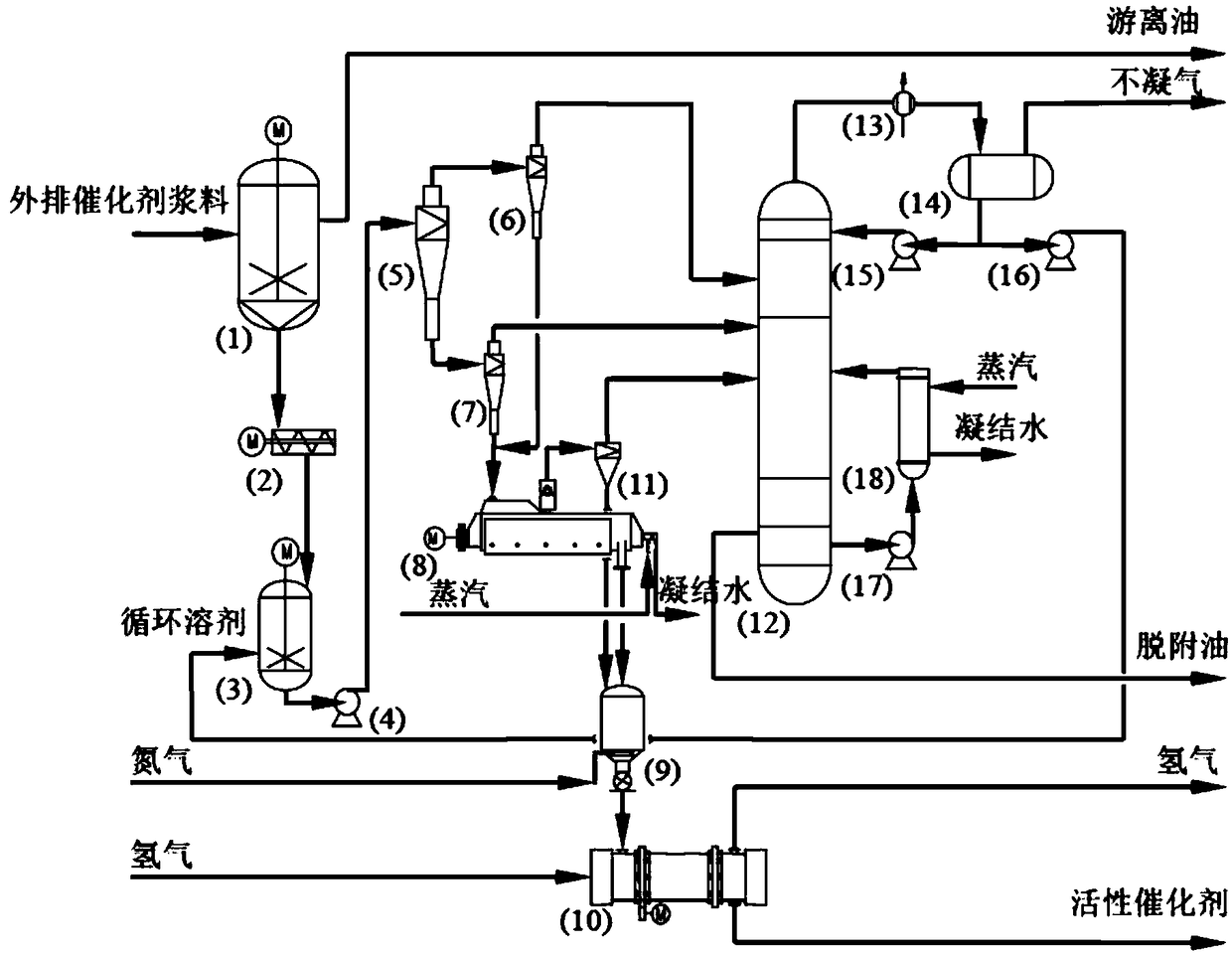

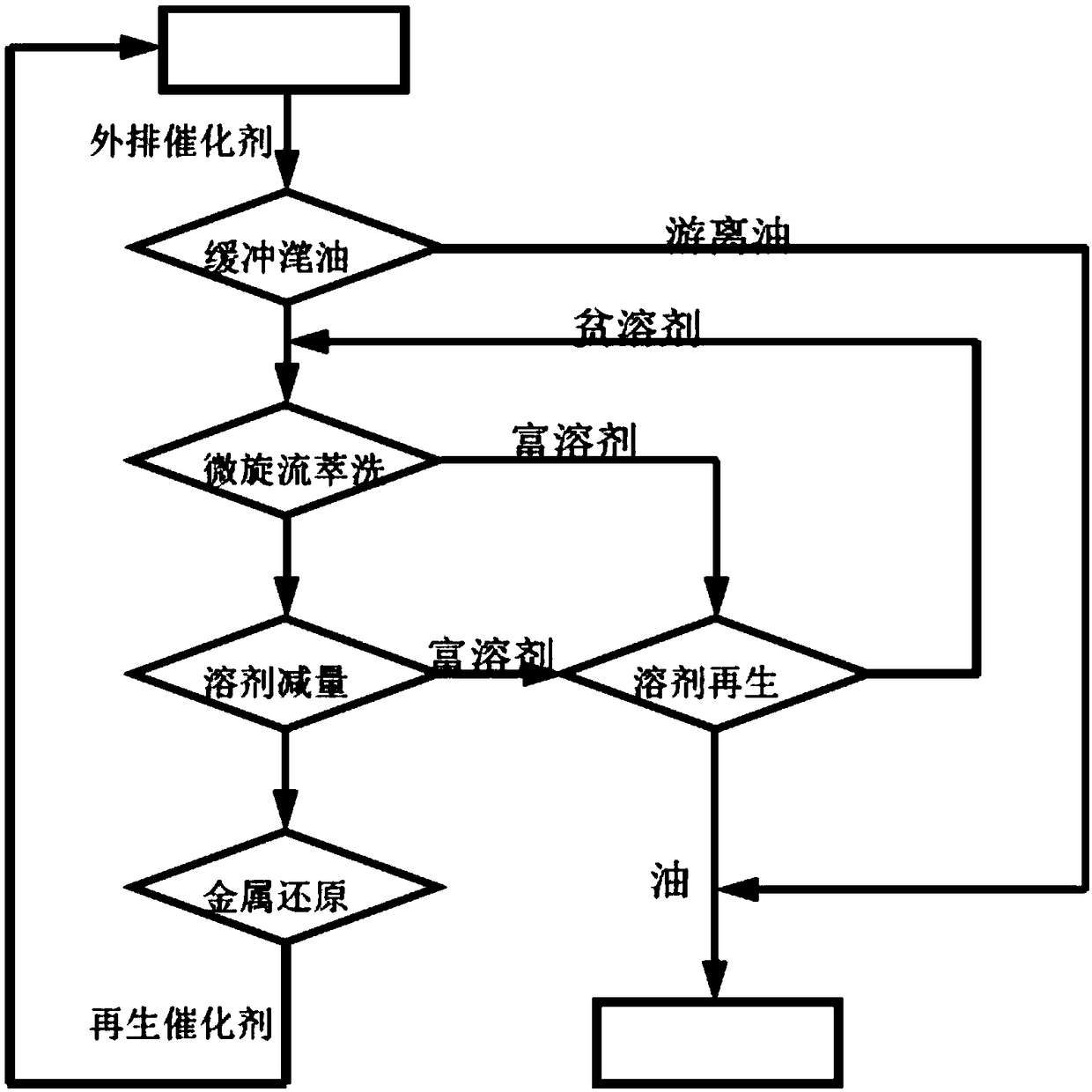

Method used

Image

Examples

Embodiment 1

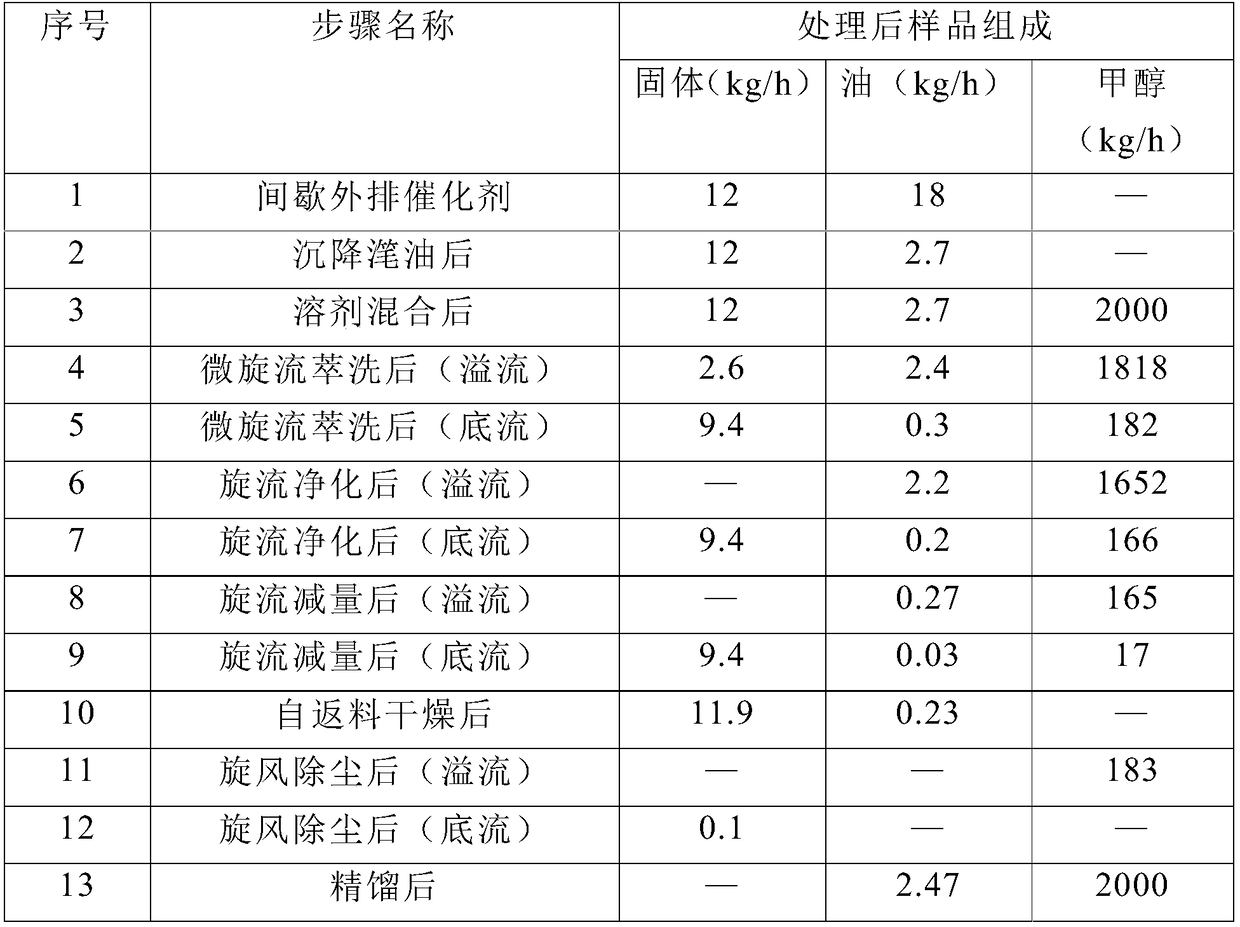

[0090] Aiming at the 30,000 tons / year ebullated bed wood tar hydrogenation device exhaust catalyst regeneration treatment process, according to the method of the present invention, using methanol (boiling point 64.7 ° C) as a solvent, first carry out the ebullated bed wood tar hydrogenation exhaust catalyst Micro-swirl extraction and washing; then solvent reduction is performed on the deoiled catalyst particles to remove the organic solvent to obtain dry catalyst particles, and then enter the rotary kiln to perform hydrogen reduction on the deactivated metal particles to realize catalyst regeneration and return to boiling The bed is recycled; the rich solvent after extraction and washing is regenerated by rectification to separate the desorbed oil. After regeneration, the solvent returns to the micro-swirl extraction and washing section for recycling. The specific operation process and effect are described as follows:

[0091] 1. Properties of ebullated bed wood tar hydrogenati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com