Aluminum-based alloy

An aluminum-based alloy, a general-type technology, applied in the field of aluminum-based alloys, can solve the problems of reduced rigidity and increased rigidity, and achieve the effects of reduced thickness, improved Young's modulus, and shape design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

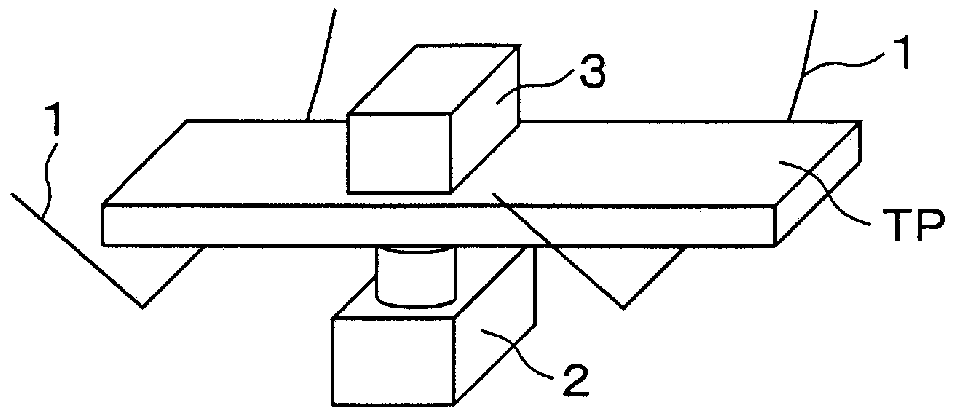

Image

Examples

no. 2 Embodiment

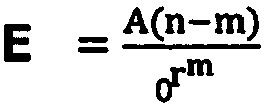

[0036] Samples were produced under the same conditions as in the first example except that an aging treatment was performed at 90° C. for 10 days, and the Young’s modulus was measured. The results are shown in Table 2. In addition, the Young's modulus calculated using the above-mentioned formula 1 is collectively recorded in Table 2.

[0037] [Table 2]

[0038]

[0039] As shown in Table 2, the Young's modulus calculated using the formula 1 is very close to the measured value, confirming the correctness of the selection of Cu, Zn, Ag, and Li.

[0040] 3. The third embodiment

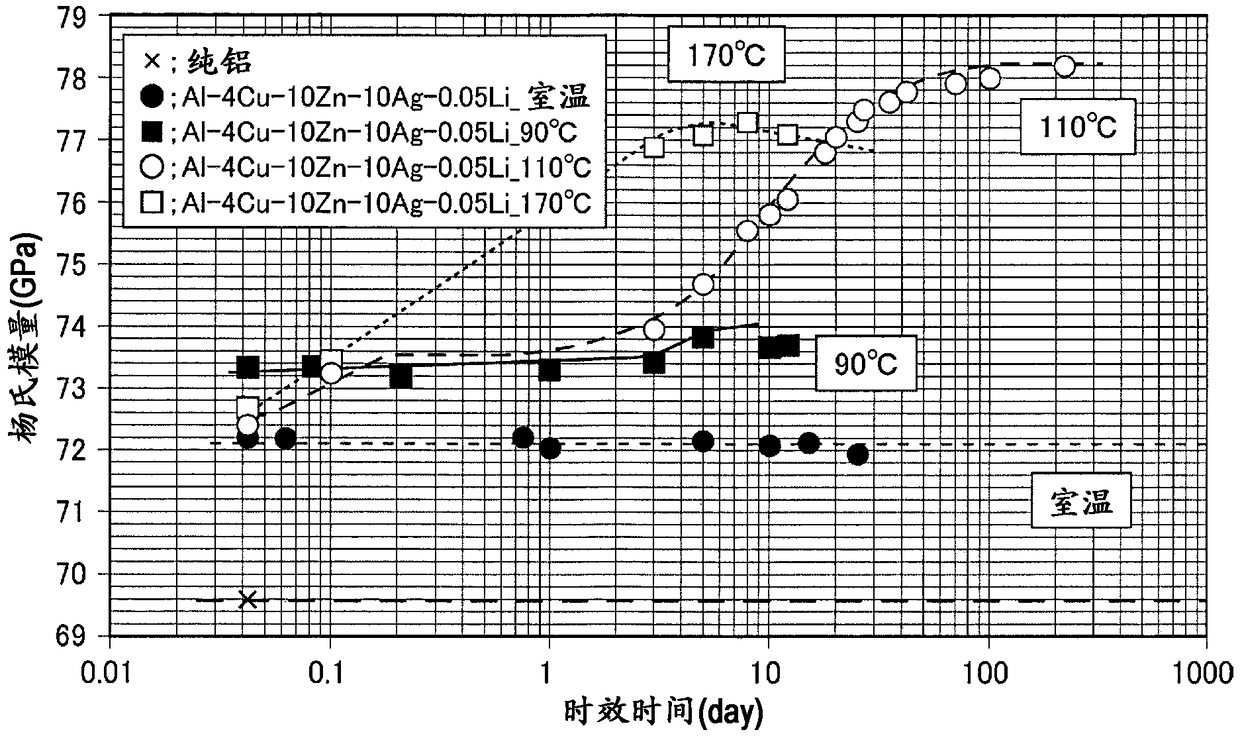

[0041] In addition to ingredients and aging treatment conditions are figure 2 Except for the cases shown, aluminum-based alloy samples were produced under the same conditions as those in the first example. according to figure 2 It can be seen that when the aging temperature is 170° C., a Young's modulus of 77 GPa or more can be obtained by aging for 240 hours. It was also confirmed that, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com