Current measurement techniques to compensate for shunt drift

A shunt resistance and current technology, applied in the field of current measurement equipment, can solve unpredictable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

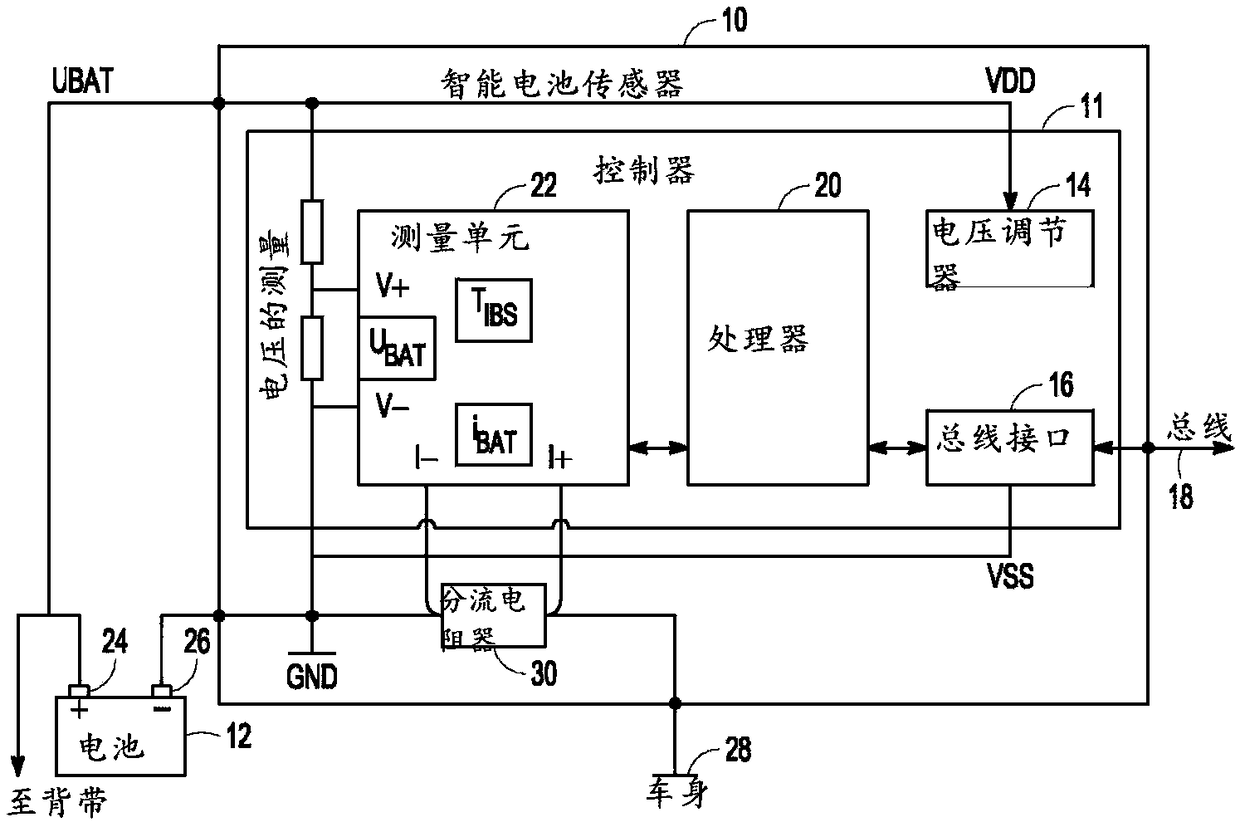

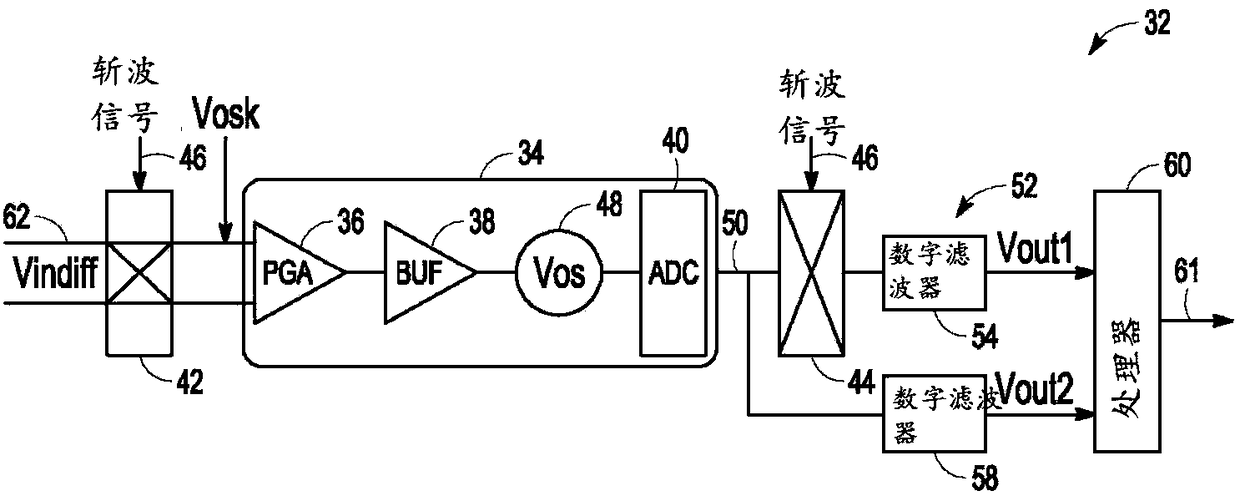

[0022] In intelligent battery sensing (IBS) applications, the state of health (SOH), state of charge (SOC) and state of function (SOF) of the battery can be determined by directly measuring the battery voltage and also measuring the current delivered by the battery in various operating modes. Current is usually measured by placing a current shunt in series with one of the battery terminals and measuring the voltage across it. Application of Ohm's law (current (I) = voltage (V) / resistance (R)) can derive the current. However, for the current measurement to be accurate, the resistance of the current shunt should be known exactly. Initially, the shunt can be measured on the factory floor, and then an offset / gain calibration can be performed on the shunt. Once the part containing the shutdown comes out of the field connected to the battery, there is no efficient way to monitor the value of the shunt itself, since there is always an unknown current (battery current) flowing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com