Low-speed high-thrust density double-layer fractional slot winding cylindrical linear motor

A double-layer fractional-slot, linear motor technology, applied in the shape/style/structure of winding conductors, electromechanical devices, electrical components, etc., can solve the problems of low thrust density, low efficiency, and small speed regulation range, and reduce positioning. The effect of reducing the cogging force and increasing the working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

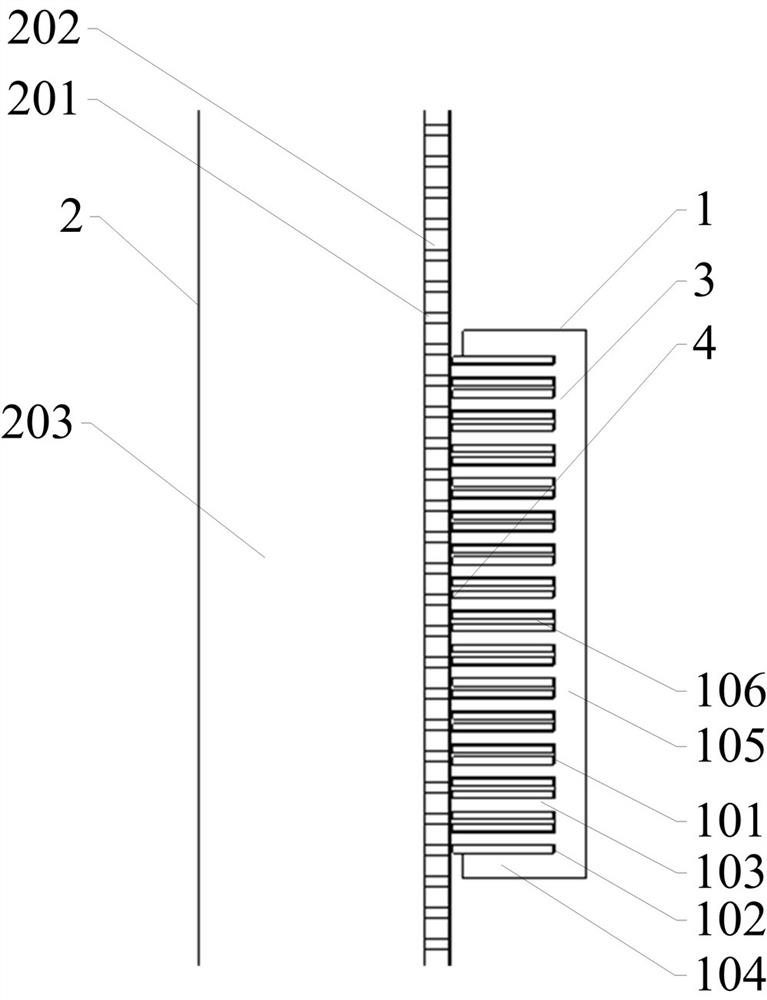

[0026] Cylindrical linear motors with low-speed and high-thrust density double-layer windings such as figure 1 As shown, including motor primary (1), motor secondary (2).

[0027] The motor primary (1) includes primary wire slots (101), primary half wire slots (102), primary teeth (103), primary end teeth (104), primary yokes (105) and pie windings (106). The slots at both ends of the motor primary (1) are primary half wire slots (102), and the remaining slots are primary wire slots (101); a set of cake windings (106) are respectively placed inside the primary half wire slots (102) at both ends; the primary wire Two sets of independent pie windings (106) are placed side by side inside the slot (101); two adjacent primary wire slots (101) are separated by primary teeth (102), and the primary half wires at the two ends of the motor primary (1) The outer side of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com