Automatic phenol water discharging device in kiln

A technology for draining Fen water and kilns, which is applied to furnaces, furnace components, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of reducing labor force and increasing labor intensity, and achieves reduction of labor intensity, sanitation and cleanliness, and improvement of on-site air quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] In this example, the relevant knowledge about Fenshui is: the main components of gas are CO and H 2 It is produced by the reaction of coal and water vapor at high temperature, so it is also called water gas, and the "water" in it refers to Fenshui.

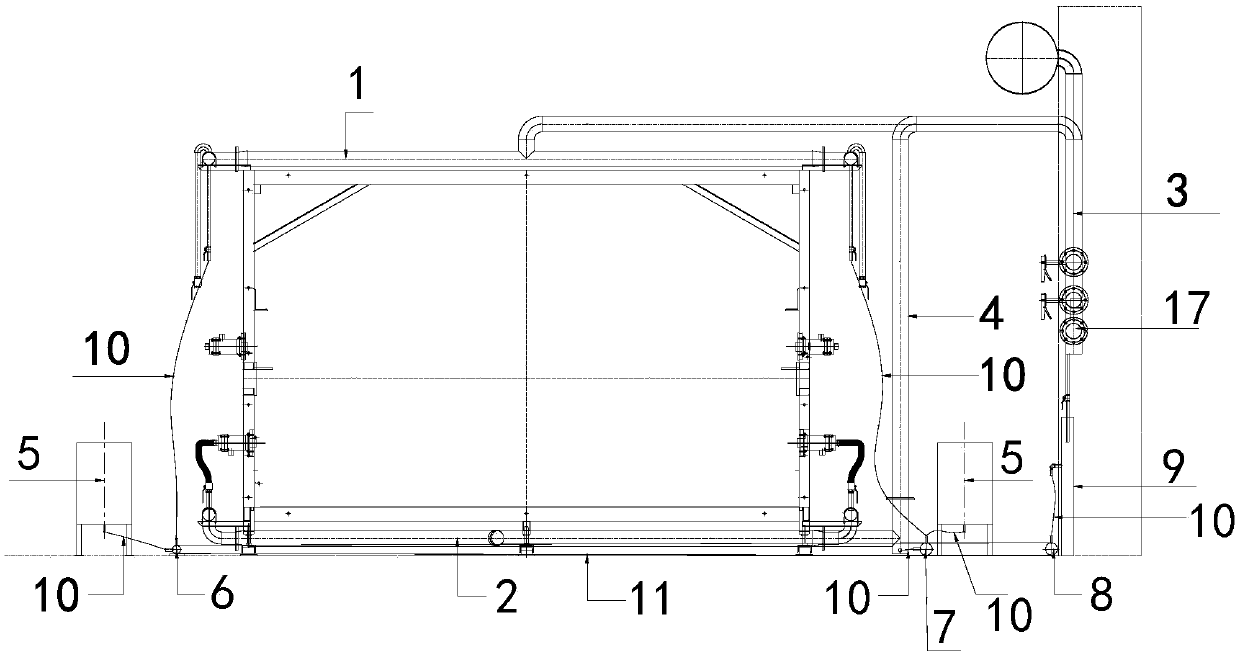

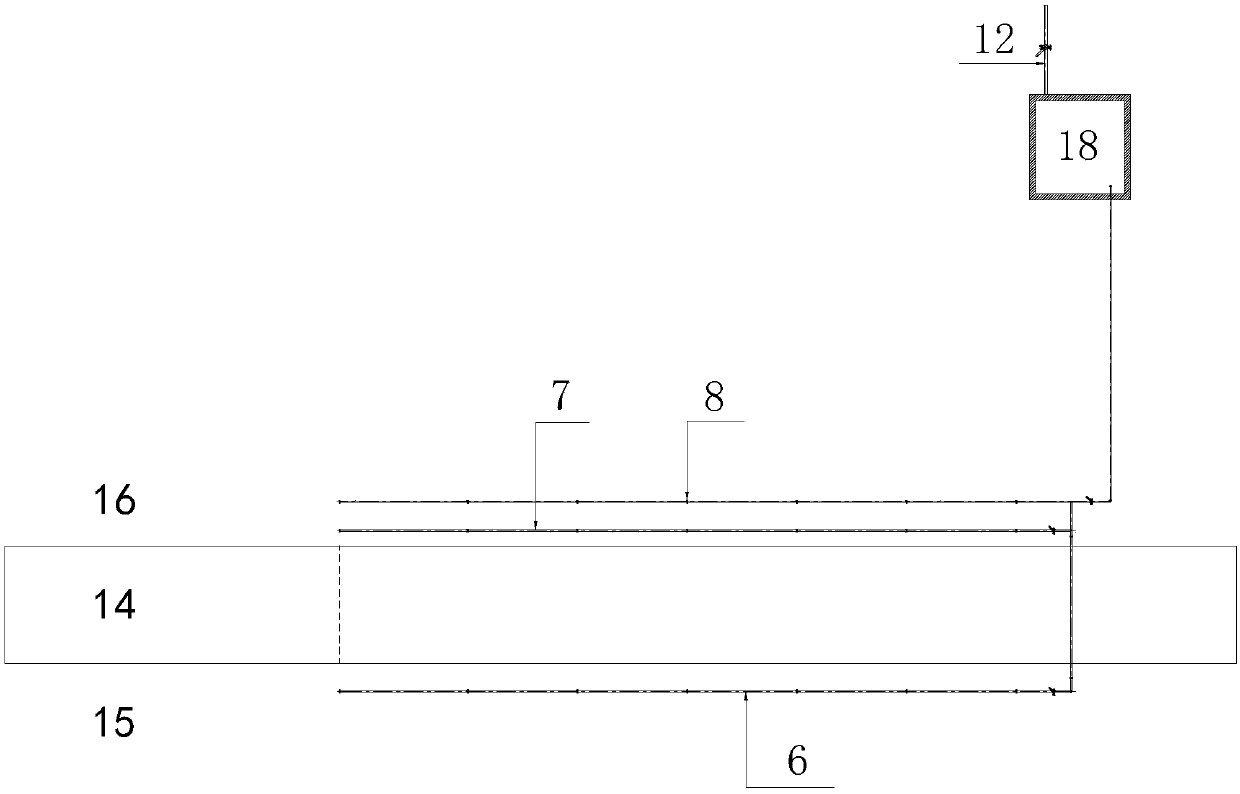

[0018] refer to Figure 1 to Figure 5 , is a kind of kiln automatic drainage device, including surface gun gas group 1, bottom gun gas group 2, surface gun control group 3, bottom gun control group 4, surface gun filter tank 5, passive side Fen water supervisor 6, Active edge Fenshui supervisor 7, control group Fenshui supervisor 8, surface gun control group Fenshui branch pipe 9; The surface gun control group Fenshui discharge port 31 is connected with the surface gun filter tank 5, the surface gun filter tank 5 is connected with the surface gun control group Fenshui branch pipe 9 through the connecting pipe 10, the surface gun gas at both ends of the surface gun gas group 1 Group Fenshui discharge port 101 is respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com