Hydrodynamic valve controller

A valve controller and water power technology, applied in the industry, can solve the problems of cable burning, unfavorable safety management, imperfect flammable and explosive liquid storage facilities, etc., to reduce fire losses, flexible selection, and improve personnel safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

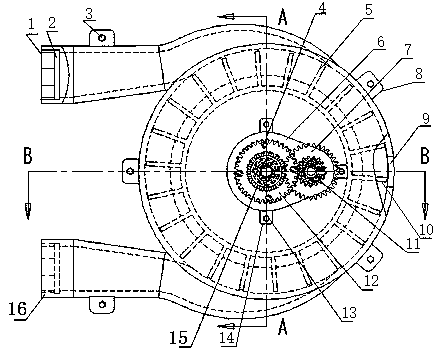

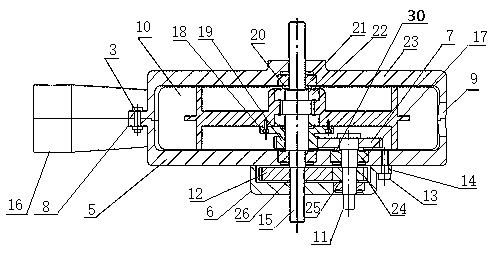

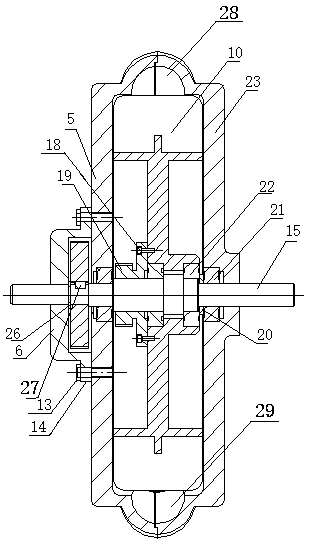

[0014] A hydrodynamic valve controller, characterized in that: the main body is composed of a pump body and a deceleration mechanism, each front pump cover 5 is aligned with the five fixing feet 18 on the rear pump cover 23, and fixed with bolt groups 3 to form a pump body There are water inlet and outlet pipes I1 and water inlet and outlet pipes II16 on the pump body shell, and pipe joints 2 are built in the nozzles. The other side of the pump body shell is provided with a pressure relief port 9, and the impeller 10 is installed on the front pump cover. 5 and the rear pump cover 23 are combined to form a groove, which is connected to the shaft II15 through two bearings III22, and can rotate around the axis of the shaft II15. The shaft II15 is limited by the shaft sleeve I20 and the two bearings II21. Two bearings II 21 are respectively connected with the front pump cover 5 and the rear pump cover 23, the front pump cover 5 and the rear pump cover 23 limit and support the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com