A method for pre-assembling steel structure trusses of super high-rise buildings

A pre-assembled and reinforced layer technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of inconvenient pre-assembly, high construction cost, and low construction efficiency, so as to increase site utilization and reduce site Occupying and reducing the effect of working at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Example: see Figure 1 to Figure 8 , a super high-rise building reinforced layer steel structure truss pre-assembly method, comprising the following steps:

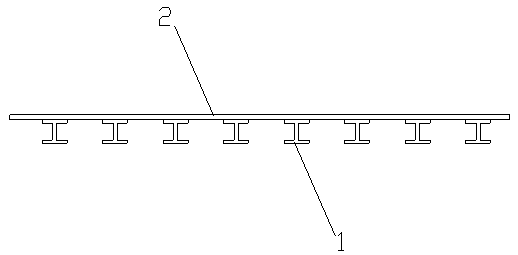

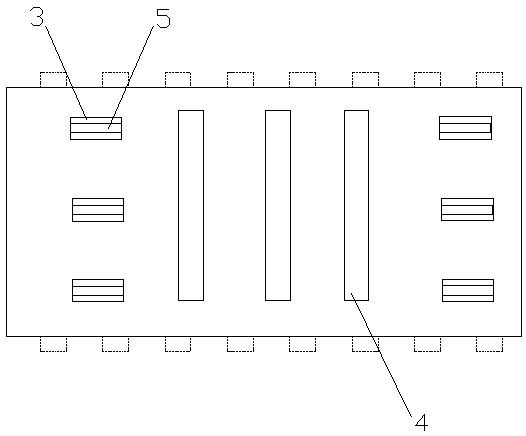

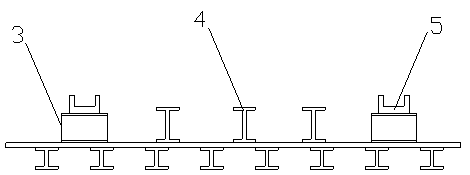

[0057] 1) Set up a pre-assembled platform on the ground in the factory: the pre-assembled platform includes several first H-shaped steels 1 and platform plates 2, the first H-shaped steels 1 are parallel to each other, and the upper flanges of all the first H-shaped steels 1 The plates are located on the same level, and the distance between two adjacent first H-shaped steels 1 is 0.5-1m; the platform plate 2 is laid on the upper flange plate of the first H-shaped steel 1 and connected with the upper The flange plates are fixedly connected, and the length direction of the platform plate 2 is perpendicular to the length direction of the first H-shaped steel 1; wherein, the platform plate 2 is formed by welding several steel plates. During the assembly process, the first H-shaped steel 1 is placed at a higher positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com