Construction method of special shaped curved surface concrete thin plate

A special-shaped curved surface and construction method technology, which is applied to arch structures, dome structures, building components, etc., can solve the problems of self-heavy, high cost of manpower and material resources, and low utilization rate of custom-made steel formwork, so as to reduce the emission measurement Difficulty and labor intensity, the effect of saving organizational time and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A construction method for a special-shaped curved concrete slab, the specific implementation method is as follows:

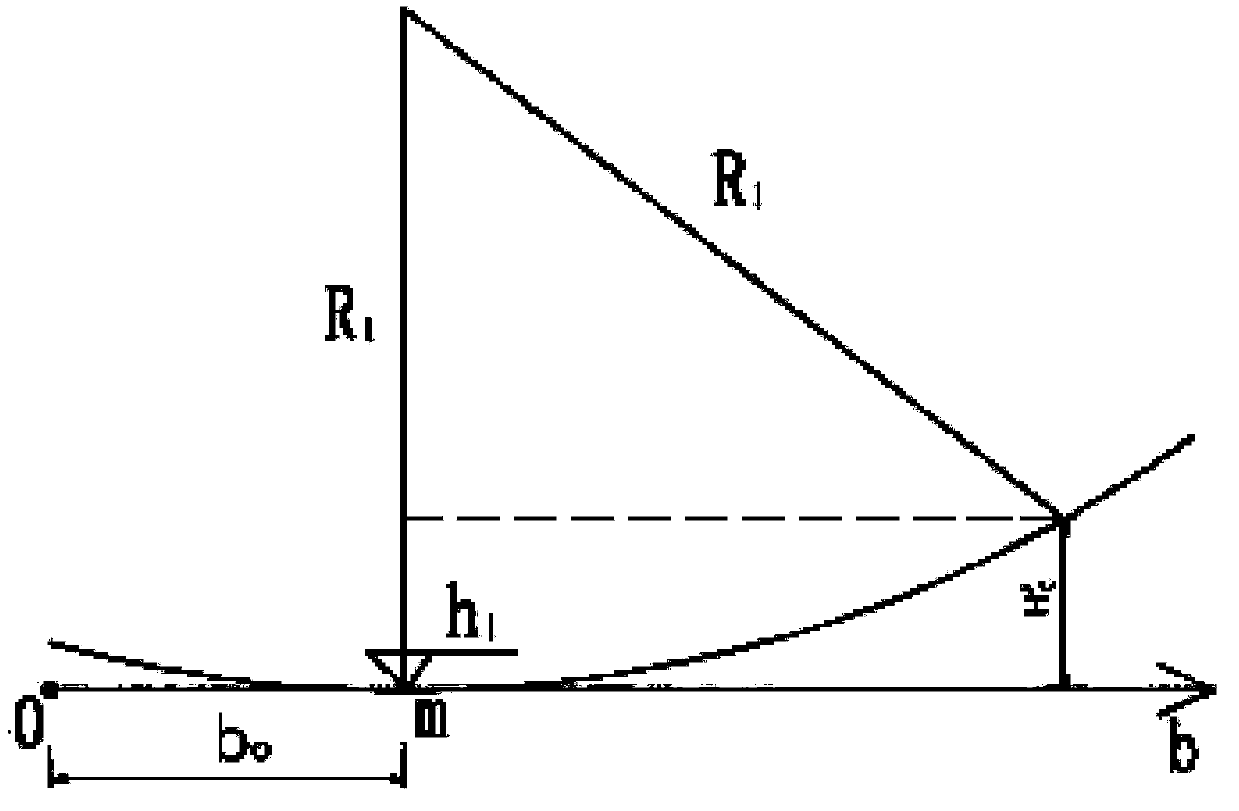

[0043] 1. Axis elevation measurement

[0044] In order to accurately and quickly measure the axis elevation of the thin plate on the curved surface, the coordinate grid measurement and positioning method is used to project the spatial surface horizontally, and divide the projection surface into several grids of 1000mm×1000mm or smaller, and then apply the formula to calculate the horizontal projection Each grid node in the surface coordinate system corresponds to the elevation of the point on the space surface, and then the elevation is marked on-site, as the basis for erecting and supporting the formwork, and all the calculated node elevations are connected together to form A smooth surface2 such as figure 1 shown.

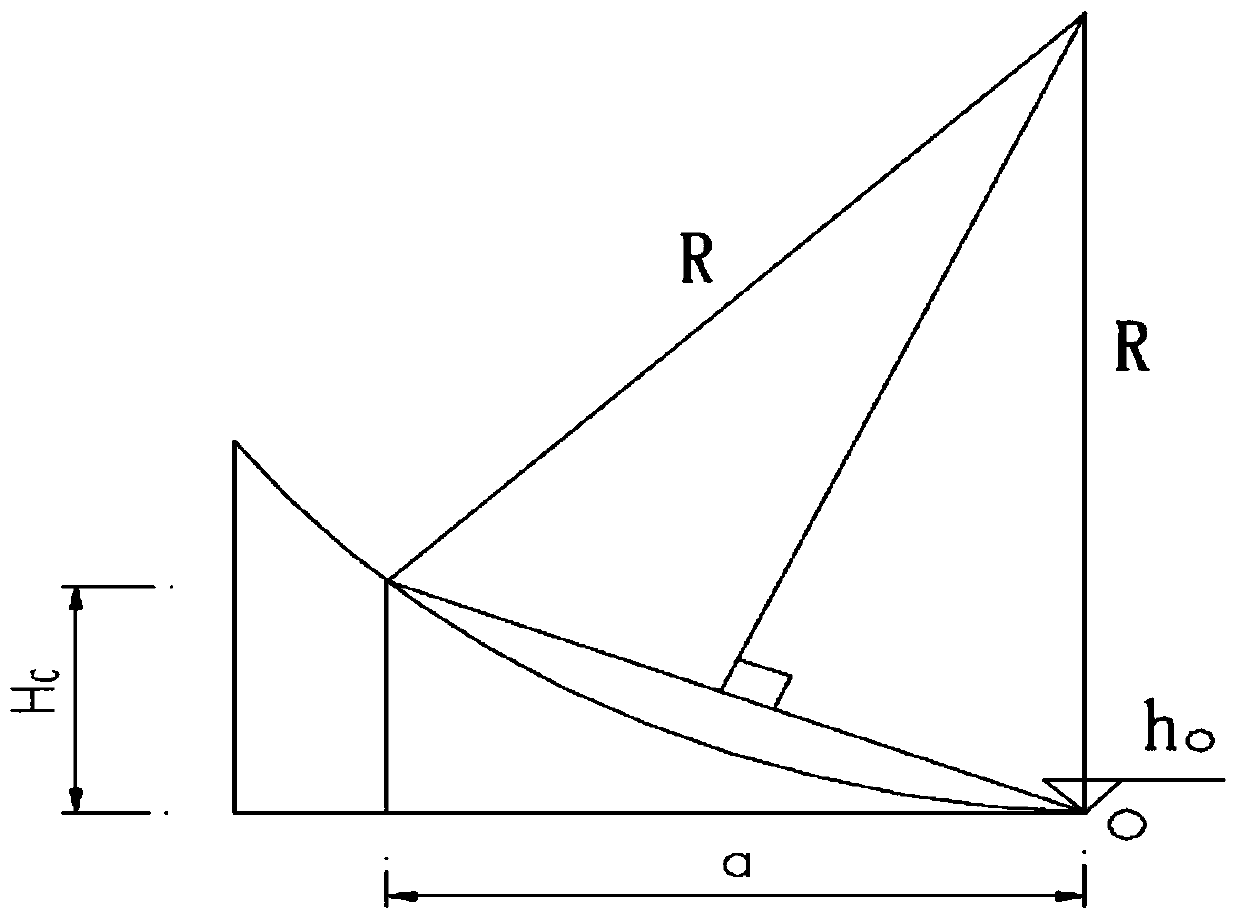

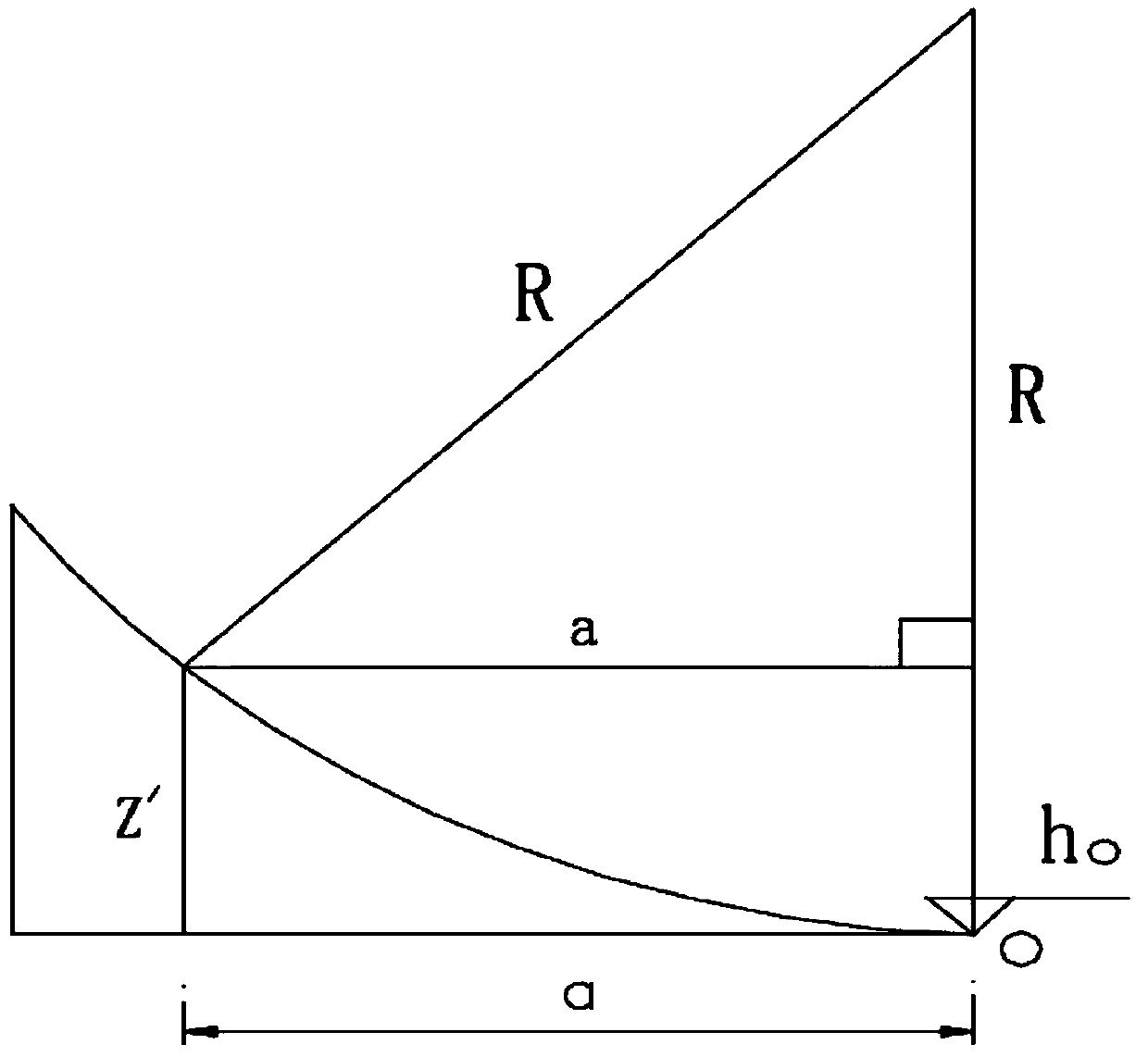

[0045] The specific application formula is as follows:

[0046] 1.1 Calculate the vertical elevation Hc of the curve on the left project...

Embodiment 2

[0076] The rest are the same as in Embodiment 1, the difference is that: according to the different curvatures of the curved surface sheet design, the layered height of the concrete pouring on both sides of the relative boundary line 10 is controlled, and the layered height is 600mm. Concrete is piled up; the general direction of advancement is also implemented in sections, controlled at a height of 800mm.

Embodiment 3

[0078] The rest are the same as in Embodiment 1, the difference is that: according to the different curvatures of the curved surface sheet design, the layered height of the concrete pouring on both sides of the relative boundary line 10 is controlled, and the layered height is 900mm, and the layered height is 900mm, and then it will go up after the vibration is tapped in place. Concrete is piled up; the general propulsion direction is also implemented in sections, controlled at a height of 1200mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com