Cap type beam-column connection piece, beam-column assembly structure using beam-column connection piece and mounting method

A beam-column connection and assembly structure technology, which is applied in the direction of building construction and construction, can solve the problems of inability to apply in a large area, weak strength of connection nodes, and weakening of strength, and achieve the effect of simple and reliable assembly method and improved connection safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose of the present invention and the advantages of the technical solution more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

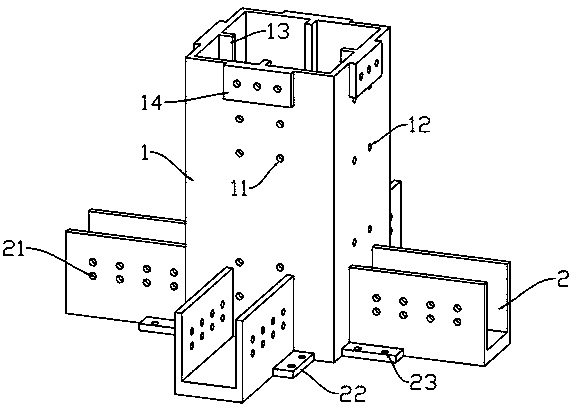

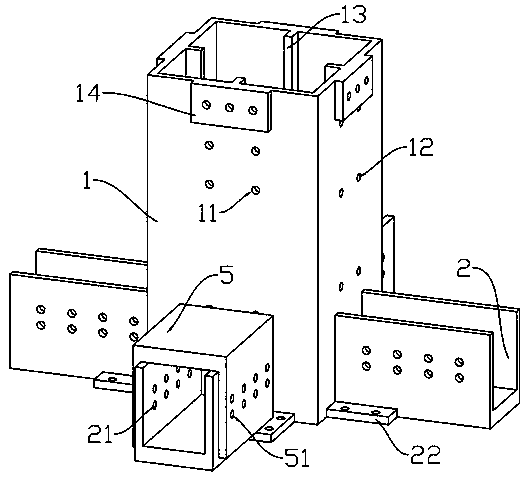

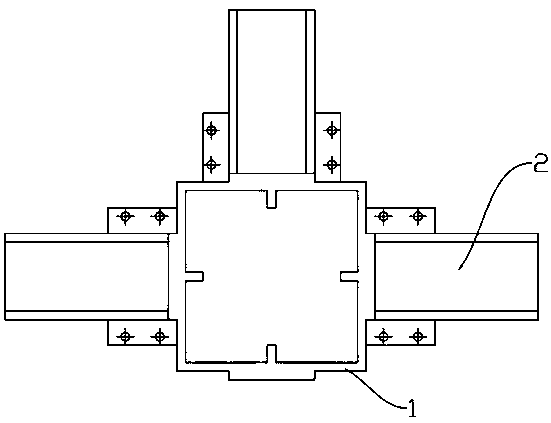

[0032] as attached figure 1 As shown, the hat-shaped beam-to-column connector can be formed by welding galvanized steel sheets or integrally cast and processed. The column 3 is fixedly connected to the sleeve 1 and several slots 2 for fixing the beam 4 . The inside of the sleeve 1 is hollow and penetrates up and down. The overall structure is square on the outside and square on the inside or square on the outside. In this embodiment, the structure of the outside and inside is adopted. A plurality of through-through first installation holes 11 are opened from top to bottom on two opposite sides of the sleeve 1 , and a plurality of through-through second installation holes 12 are opened from top to bottom on the other two opposite sides. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com