Connecting structure of goods van lampshade

A technology for connecting structures and lampshades, which is applied to vehicle components, optical signals, signal devices, etc., can solve the problems of inconvenient and laborious disassembly, and achieve the effects of cost saving, simple disassembly, labor-saving convenience, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

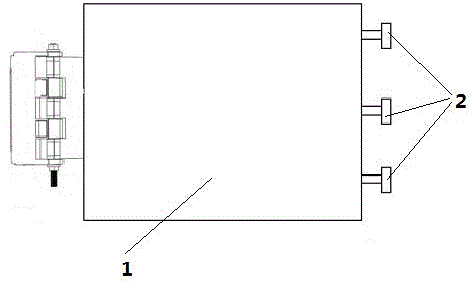

[0013] Such as figure 1 and 2 Shown: a connection structure of a lampshade for a truck, including a lampshade 1, one side of the lampshade 1 is hinged to the vehicle body, and the opposite side is detachably clamped to the vehicle body.

[0014] The side of the detachable clamping connection with the car body is evenly provided with three buckles 2, the shape of the buckles 2 is U-shaped, the hook 3 on the buckle 2 is a right angle, and the car body is provided with There is a slot 4 matching the hook 3, and the lampshade 1 and the buckle 2 are integrally injection-molded of transparent plastic.

[0015] The number of buckles 2 depends on the size of the lampshade 1. When the lampshade 1 is installed, one side of the lampshade 1 is hinged to the vehicle body, and the opposite side is inserted into the slot 4 through the hook 3. ; When disassembling, just pull the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com