A press-fit marine bearing

A press-fit, marine technology, applied in the direction of shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems of falling off, loud noise, excessive friction of rubber lining, etc., to achieve stable connection, reduce noise, and avoid detachment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

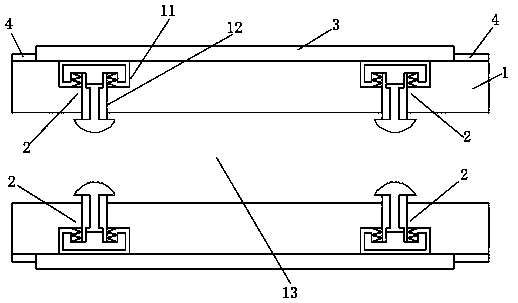

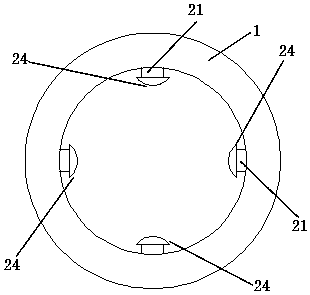

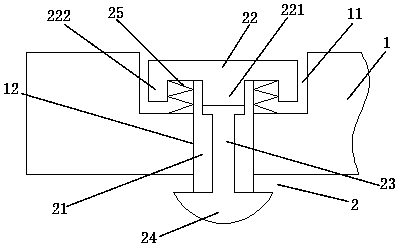

[0023] like Figures 1 to 5 As shown, a press-fit marine bearing includes a bearing sleeve 1 and a pressure-resisting mechanism 2; the bearing sleeve 1 is in an annular sleeve structure, and a shaft cavity 13 is arranged inside the bearing sleeve 1; the pressure-resisting mechanism 2 is set There are multiple; the two ends of the bearing sleeve 1 are provided with a plurality of installation grooves 11; the inside of the installation groove 11 is provided with a thread groove 12; the thread groove 12 communicates with the shaft cavity 13; A pressing mechanism 2 is respectively installed in the installation groove 11, such as figure 2 As shown, four pressing mechanisms 2 can be evenly distributed, and four pressing blocks 24 are used to support and limit the rotation shaft; Drive plate 22, annular elastic body 25; said external thread cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com