Installation method of box-shaped rod piece butt plates of steel structure arch bridge

An installation method and technology of docking plates, applied in arch bridges, bridge forms, bridges, etc., can solve time-consuming problems, reduce the number of docking times, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

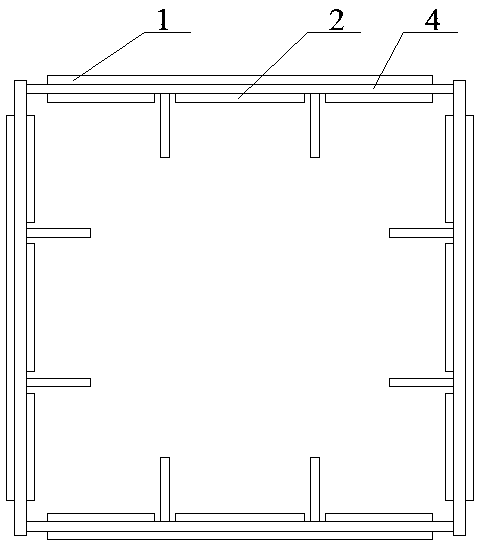

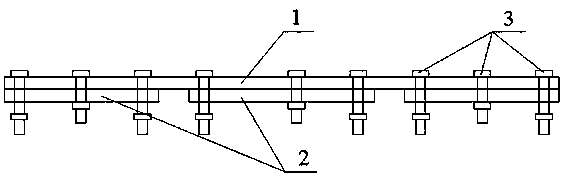

[0020] see Figure 1 to Figure 7 , a method for installing the butt joint plates of box-shaped rods of steel structure arch bridges. In this method, before the rods are hoisted, after all the butt-joint plates on the inner and outer sides of each side of the box-shaped rods are spliced, the butt joints are manually cooperated with forklifts. The board is installed as a whole to the corresponding position of the bar.

[0021] The following takes the installation of the butt plate of the top plate on the rod as an example to illustrate:

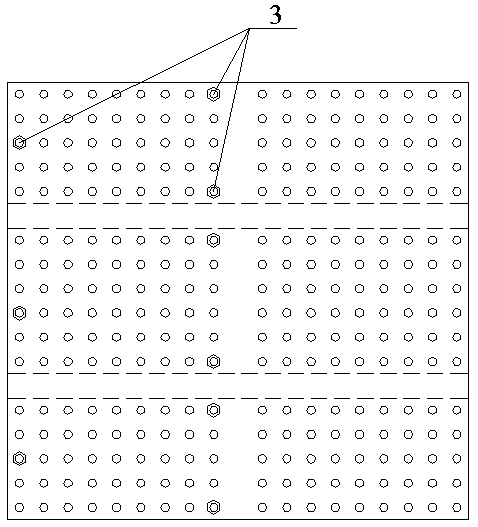

[0022] The butt plates corresponding to the top plate 4 on the rod are divided into four pieces: one outer butt plate 1 and three inner butt plate 2. When assembling, the four butt plates are stacked together according to the spatial position, and each inner butt plate 2 and the outer butt plate 1 are fixed with thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com