Combined type casement window system

A casement window and combined technology, which is applied in the field of doors and windows, can solve problems such as air leakage, leakage, and air leakage, and achieve the effects of improving wind resistance performance, increasing service life, and ensuring connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

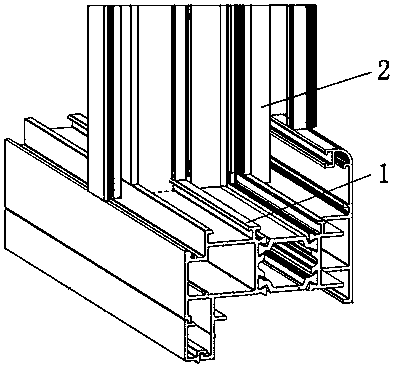

[0046] A combined casement window system, comprising a secondary frame 10, a window frame 1, a center sash 2 and a sash 3, the window frame 1 is provided with a window frame water blocking windshield 1a, a connecting plate 1b and a window frame stopper Plate 1c, the sub-frame 10 is provided with a sub-frame water-blocking windshield 10a; the window frame 1 is connected to the sub-frame 10 through the connecting plate 1b; The wind board 10a is bonded to the window frame water blocking windshield 1a; the window frame 1 and the center leg 2 are respectively provided with a bonding edge 9, and the window frame 1 is fastened and connected to the center leg 2 through the bonding edge 9. Effectively improve positioning accuracy, waterproof and windproof performance.

Embodiment 2

[0048] A combined casement window system, comprising a secondary frame 10, a window frame 1, a center sash 2 and a sash 3, the window frame 1 is provided with a window frame water blocking windshield 1a, a connecting plate 1b and a window frame stopper Plate 1c, the sub-frame 10 is provided with a sub-frame water-blocking windshield 10a; the window frame 1 is connected to the sub-frame 10 through the connecting plate 1b; The wind board 10a is bonded to the window frame water blocking windshield 1a; the window frame 1 and the center leg 2 are respectively provided with a bonding edge 9, and the window frame 1 is fastened and connected to the center leg 2 through the bonding edge 9. The sub-frame 10 is also provided with a sub-frame limiting water-blocking plate 10b and a sub-frame limiting plate 10c, the sub-frame limiting water-blocking plate 10b is attached to the wall or the wall insulation layer, and the sub-frame limiting plate 10c It is attached to the wall or the wall pl...

Embodiment 3

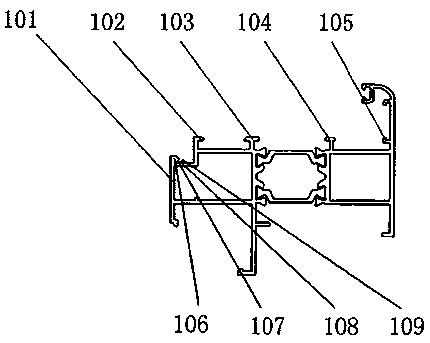

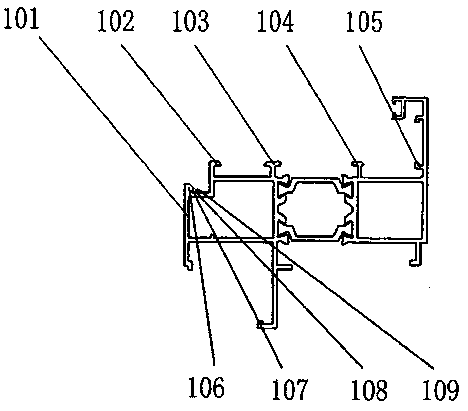

[0050] On the basis of Example 2, the window frame 1 is respectively provided with a window frame locking edge I101, a window frame locking edge II102, a window frame locking edge III103, a window frame locking edge IV104 and a window frame locking edge V105, Center stile 2 is respectively provided with center stile lock side Ⅰ201, center stile lock side Ⅱ202, center stile lock side Ⅲ203, center stile lock side Ⅳ204, center stile lock side Ⅴ205; window frame lock side and center stile The buckle sides are locked and fitted in turn to form a 5-point buckle and double butterfly structure. The multi-sided fit is convenient for observing and determining the position during the installation operation, and improves the installation accuracy. The wind resistance level reaches level 9 of GB / T7106-2008. The mutual bonding structure makes the overall thickness of the window frame and center poles controlled within the range of 60-110mm. Guaranteed wind resistance level while reducing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com