Method for efficiently synthesizing Neotame

A neotame and high-efficiency technology, applied in the field of food additives, can solve the problems of low product purity, complicated operation, high cost, etc., and achieve the effect of less reaction impurities, simple operation and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

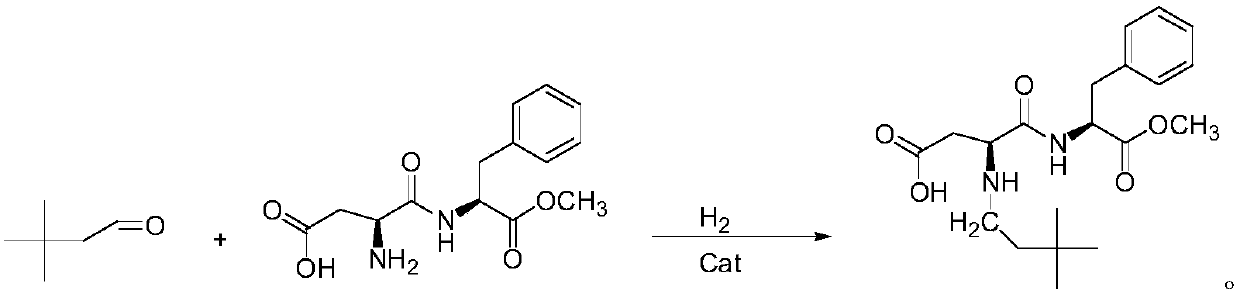

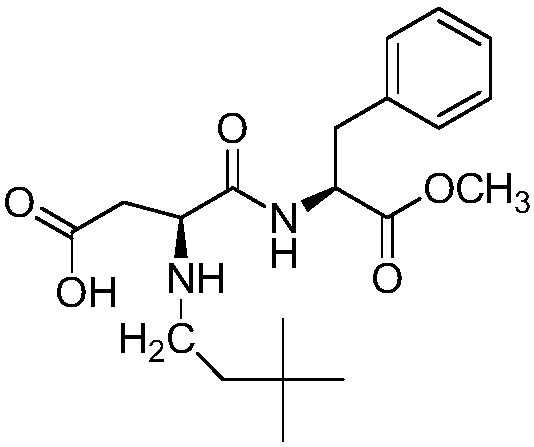

Method used

Image

Examples

Embodiment 1

[0026] Pump 100kg of ethanol into a 500-liter high-pressure reactor, add 12.5kg (42.5mol) of aspartame, and then add 4.2kg of 3,3-dimethylbutyraldehyde (41.9mol), stir and dissolve, and add 0.45Kg of Raney nickel Catalyst, close the valve, replace the system with hydrogen after nitrogen replacement three times, keep the hydrogen pressure in the system at 1.0Mpa after the replacement, start stirring, adjust the speed to 30 (equivalent to 180r / min), heat with hot water, and control the reaction temperature at 50°C. After 2 hours of heat preservation and hydrogenation, the hydrogen gas was discharged, the catalyst was removed by pressure filtration, ethanol was removed by vacuum distillation, the catalyst was recovered, the filtrate was cooled to -5°C to crystallize, and the centrifuge was centrifuged to obtain the neotame product, with a yield of 97% based on aspartame. Purity (HPLC) 99.83%.

Embodiment 2

[0028] Pump 500kg of tetrahydrofuran into a 1000-liter high-pressure reactor, put in 62.5kg (212.4mol) of aspartame, and then put in 23.4kg of 3,3-dimethylbutyraldehyde (233.6mol), stir and dissolve, and put in 2.25Kg of Raney Nickel catalyst, close the valve, replace the system with hydrogen after nitrogen replacement three times, keep the hydrogen pressure in the system at 1.2Mpa after the replacement, start stirring, adjust the speed to 30 (equivalent to 180r / min), heat with hot water, and control the reaction temperature at 60°C , after 2 hours of heat preservation hydrogenation, the hydrogen gas is discharged, the catalyst is removed by pressure filtration, and tetrahydrofuran is removed by vacuum distillation, the catalyst is recovered, the filtrate is cooled to 10°C to crystallize, and the centrifuge is centrifuged to obtain the neotame product, with a yield of 96% based on aspartame. Purity (HPLC) 99.63%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com