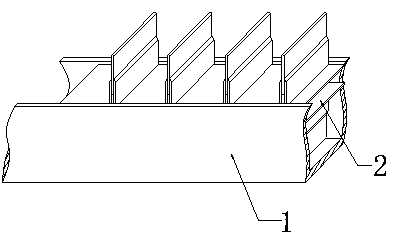

Feeding device capable of effectively preventing mechanical damage

A technology of mechanical damage and feeding device, applied in the field of mechanical equipment, can solve the problems of material damage, reduced production quality, poor conveying stability, etc., to achieve the effect of easy operation, improved production quality, and good conveying stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

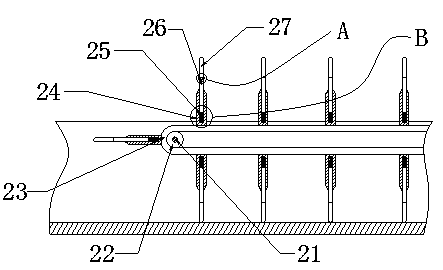

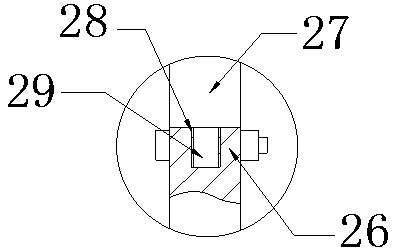

[0021] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: During use, the staff runs the motor, the motor drives the rotation shaft 21 to rotate, the rotation of the rotation shaft 21 drives the rotation of the drum 22, the rotation of the drum 22 drives the conveyor belt 23 to move, the conveyor belt 23 moves to drive the hollow plate 24 to move, and the hollow plate 24 moves. The movement of the plate 24 drives the movement of the solid plate 26, the movement of the solid plate 26 drives the movement of the rubber plate 27, and then the worker puts the material into the left end of the bracket 1. Under the action of the elastic force of the rubber plate 27, the rubber plate 27 is closely attached to the inner lower side of the bracket 1 during the moving process, thereby improving the material conveying effect. If the material is damaged, when the rubber plate 27 is seriously worn, the staff removes the bolts from the connecting holes 1 and 2, separates the protruding strips ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com