Automatic practical rotary cutting device

A rotary cutting device, practical technology, applied in forming/shaping machines, special forming/shaping machines, veneer manufacturing, etc., can solve the problems of large volume, complex structure, lack of centering function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

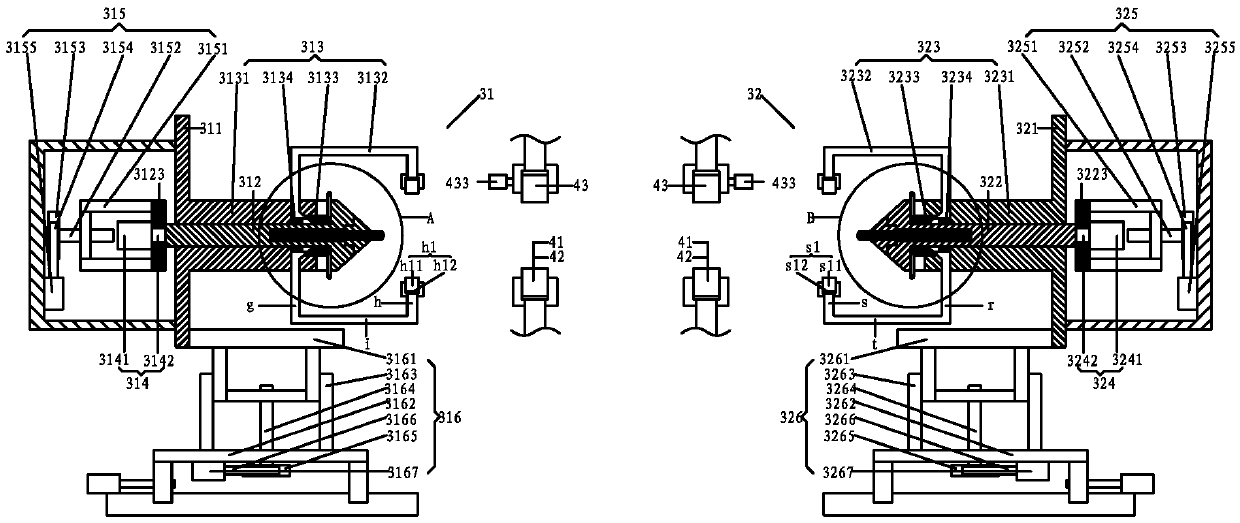

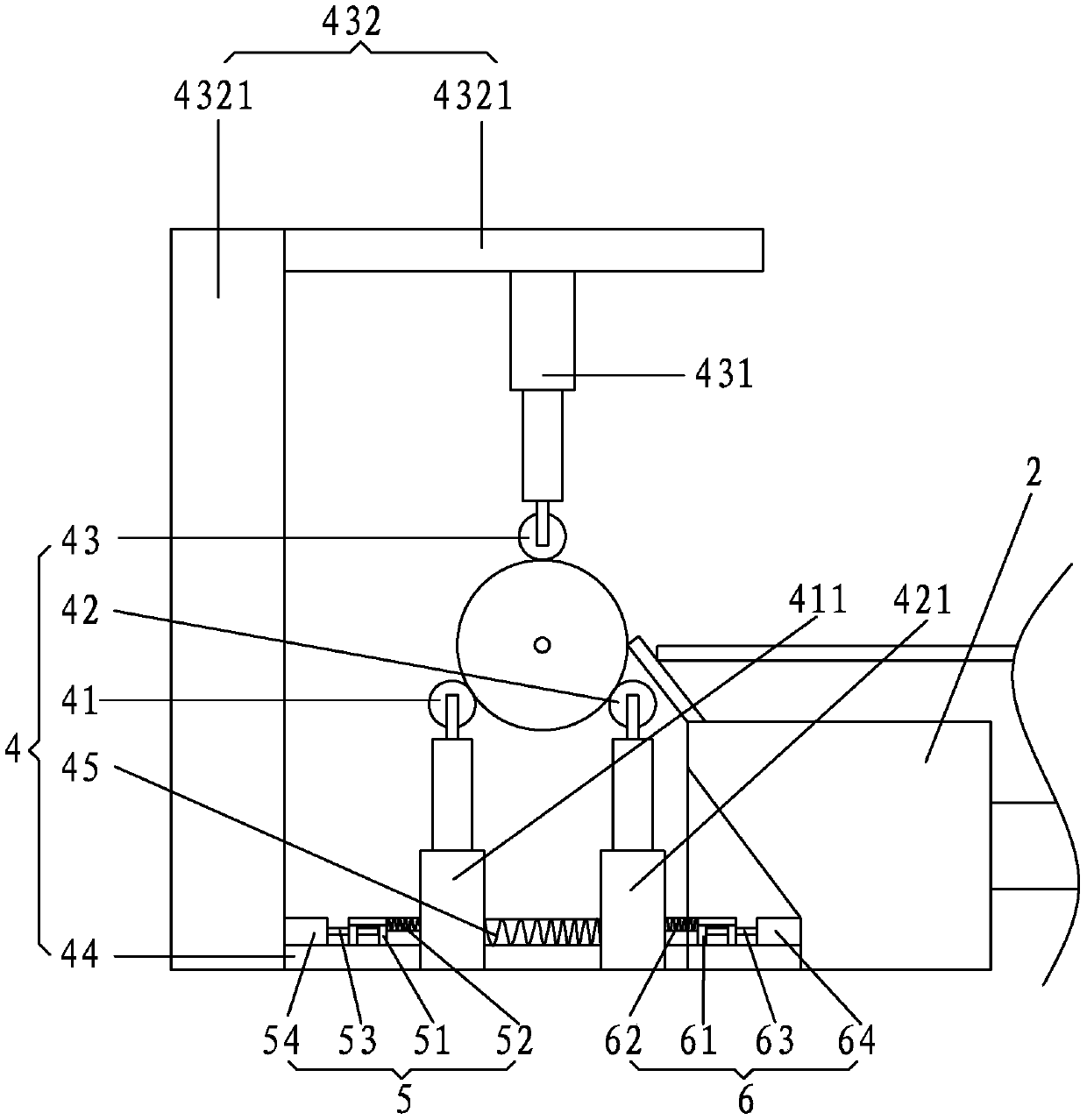

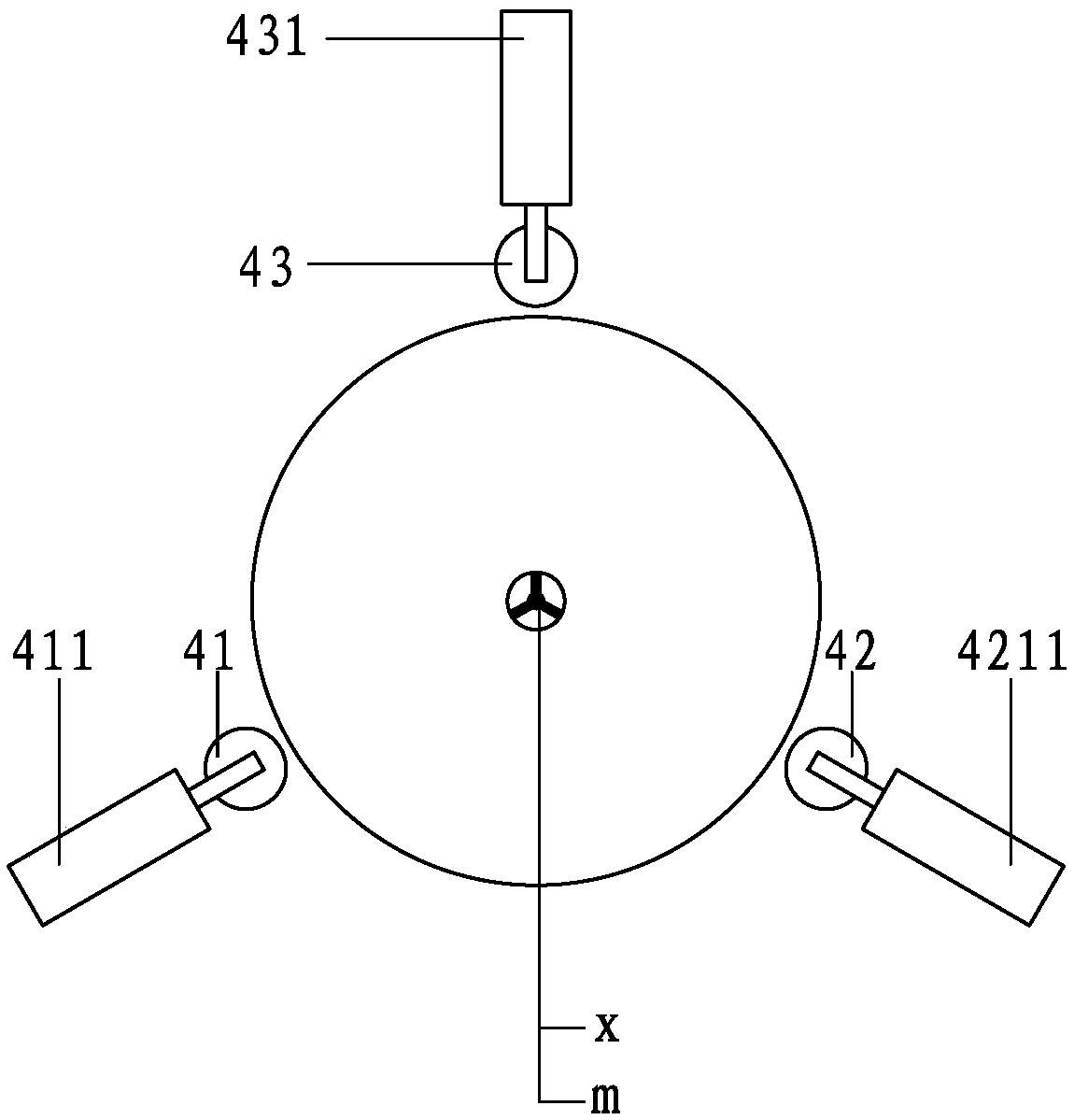

[0041] A kind of automatic practical rotary cutting device of the present invention, as Figure 1-6 As shown, it includes a frame, a rotary cutting device 2 and a clamping shaft located on the frame; the clamping shaft includes a first clamping portion 31 at one end of the log, and a second clamping portion 32 at the other end of the log; Both the first clamping part 31 and the second clamping part 32 have a proximal end facing the direction of the log and a distal end facing the opposite direction; it is characterized in that it also includes a positioning and rotating drive device 4 for positioning and rotating the log;

[0042] The first clamping part 31 includes a first main base plate 311 perpendicular to the log, a first positioning shaft device passing through the first main base plate 311, and a first positioning sleeve devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com