Self-pressing type hole punching device and punching method

A punching device and punching technology, applied in the field of punching dies, can solve problems such as unsatisfactory punching effect and slow punching efficiency, and achieve the effects of saving labor intensity, convenient installation and maintenance, and reasonable and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

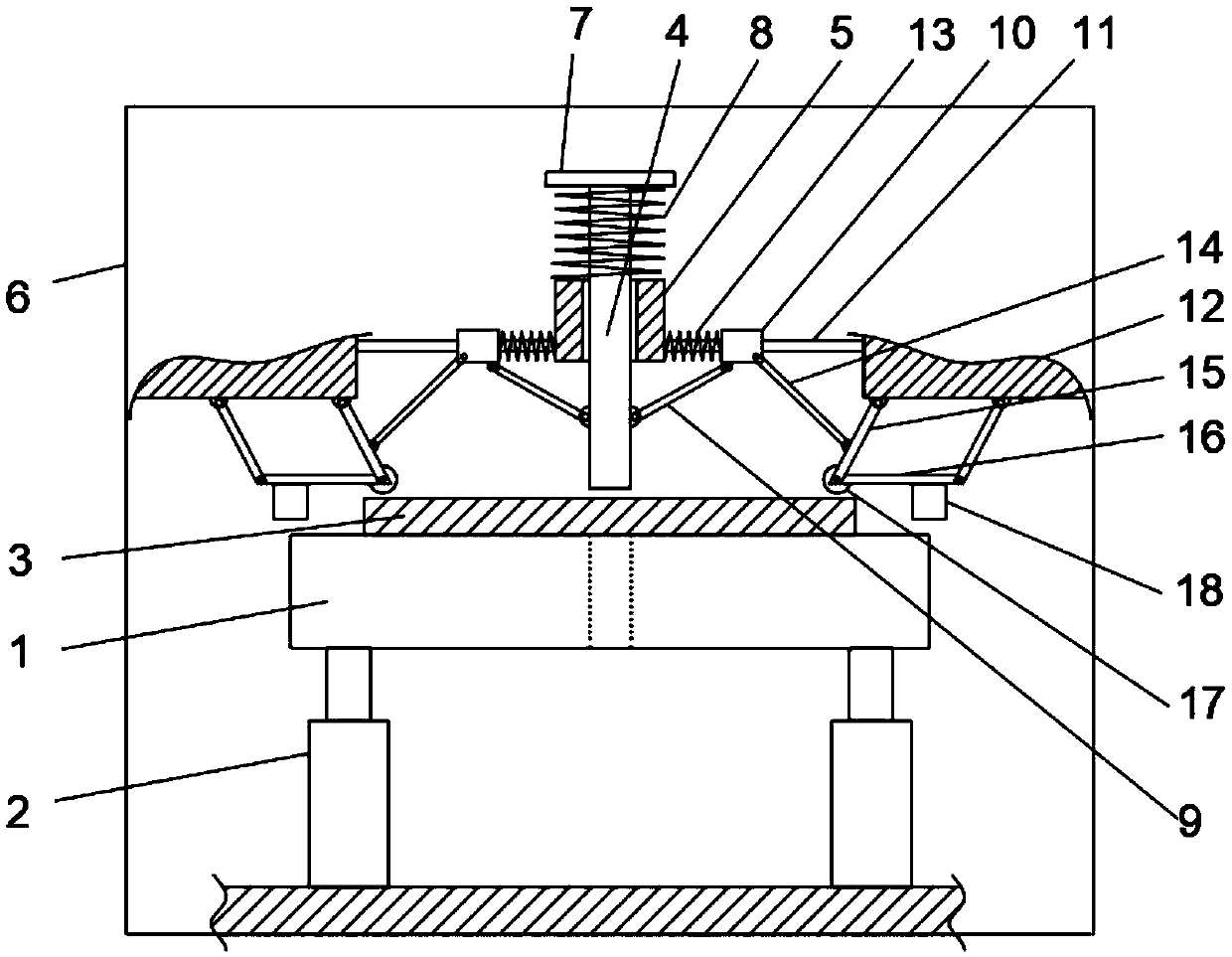

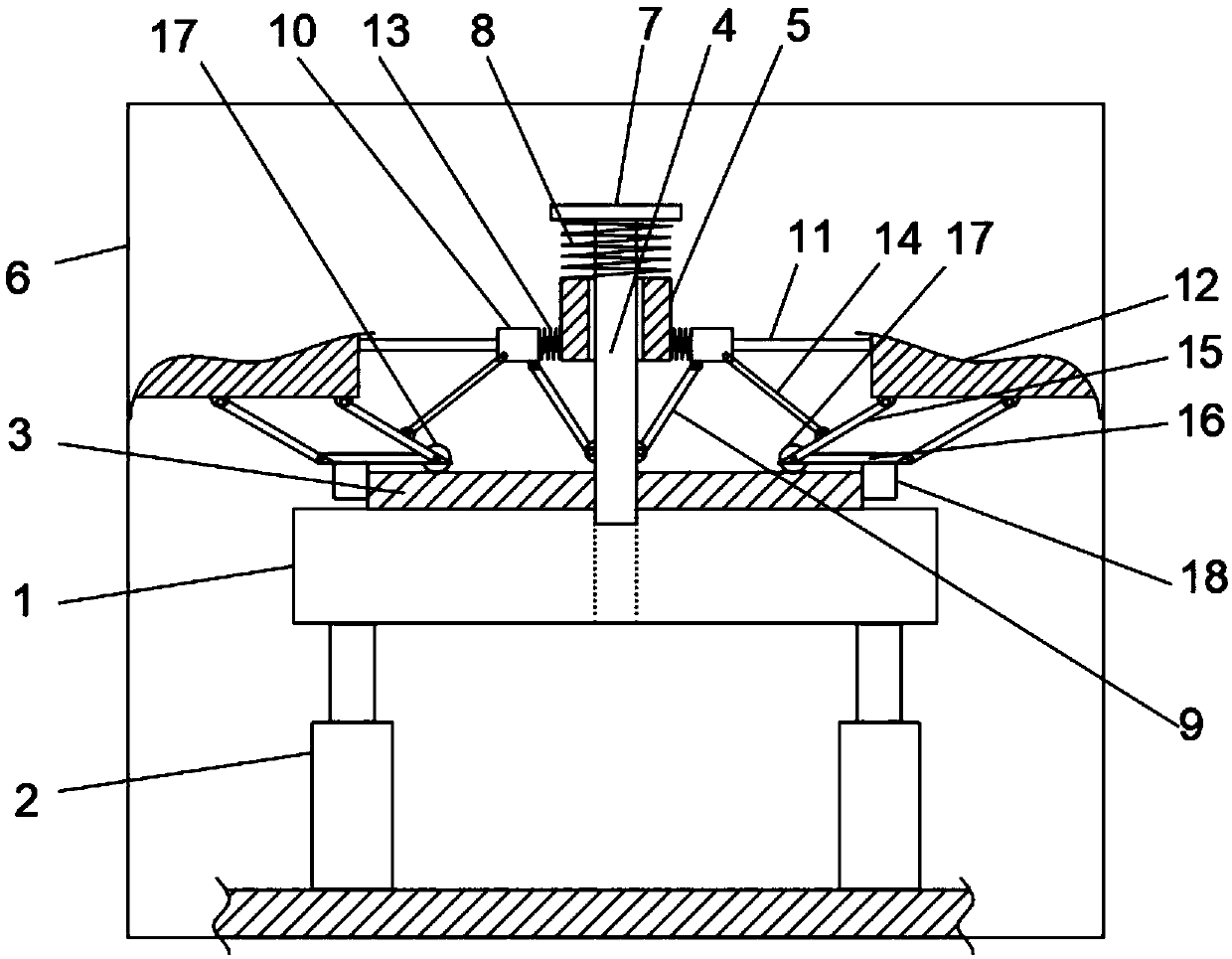

[0029] see Figure 1-2 , the present invention provides a technical solution:

[0030] A self-pressurized punching device, including a workbench 1, a cylinder 2 is provided under the workbench 1, the number of cylinders 2 can be set to two, and the workbench 1 is driven up and down by the cylinder 2, and the plate 3 is placed on the workbench 1 The upper surface of the upper surface of the plate 3 is vertically provided with a punching rod 4, and the workbench 1 is provided with a through hole with a diameter equal to or larger than the diameter of the punching rod 4, and the punching rod 4 slides through the hole. Over the limit block 5, the front side wall and the rear side wall of the limit block 5 are all fixed on the inner wall of the frame 6, and the top of the punching rod 4 is fixedly connected to the baffle plate 7 horizontally, between the baffle plate 7 and the limit block 5 The first spring 8 is arranged between the upper surface of the upper surface, the first sp...

Embodiment 2

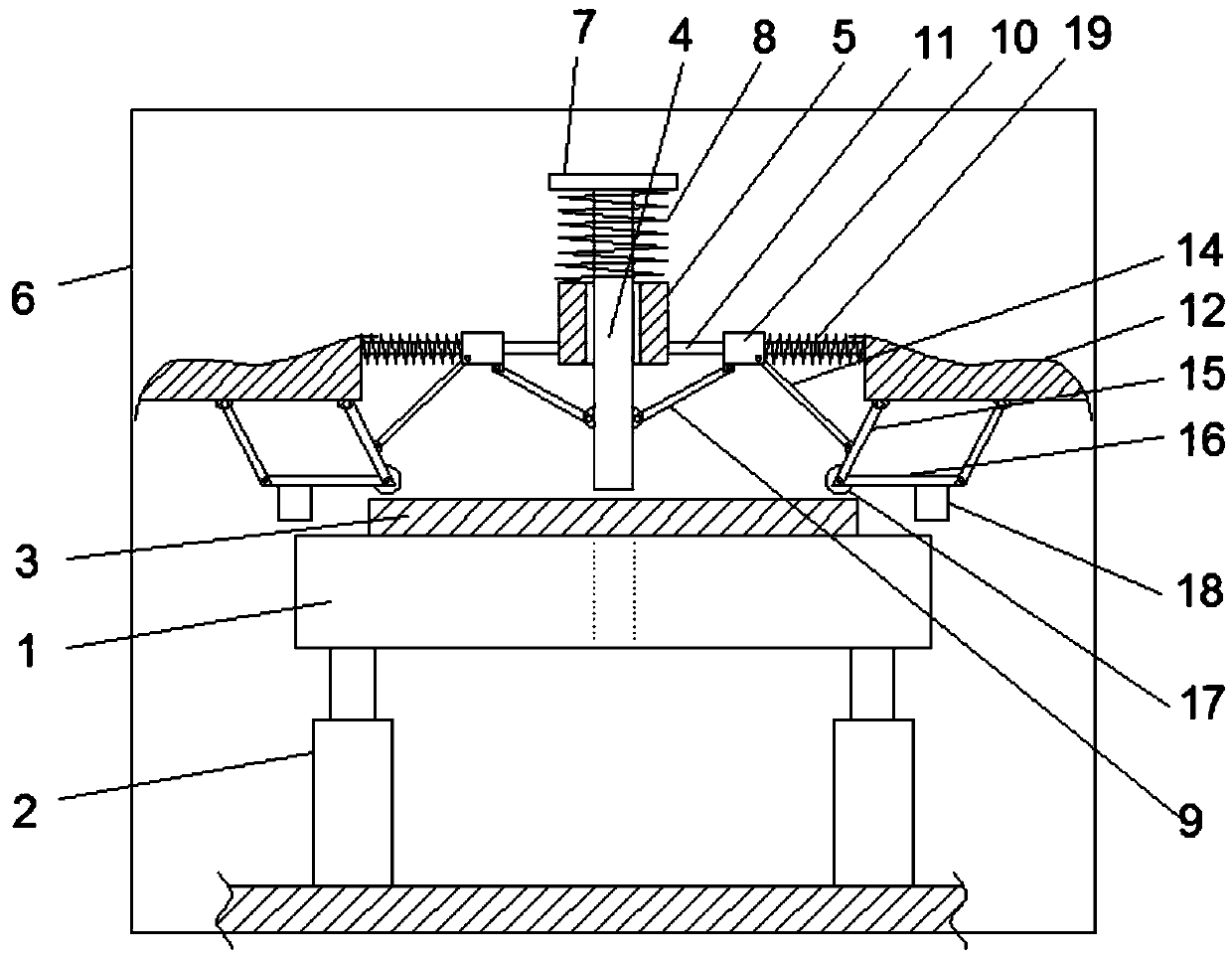

[0041] see image 3 , the second spring 13 arranged between the slider 10 and the limiting block 5 is replaced by a third spring 19 arranged between the slider 10 and the mounting block 12 , and the third spring 19 is sleeved on the slider 11 . The third spring 19 is a tension spring, which can also ensure the smooth movement of the slider 10 and the effective return of the slider 10 after the punching is completed. Other structures and principles are the same as those in Embodiment 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com