Bag deduster prepared by reconstructing electric deduster

A bag-type dust collector and electrostatic precipitator technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of difficulty in setting up air ducts, long construction period, shortened transformation period, etc. Retrofit period, improve construction efficiency, and make full use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

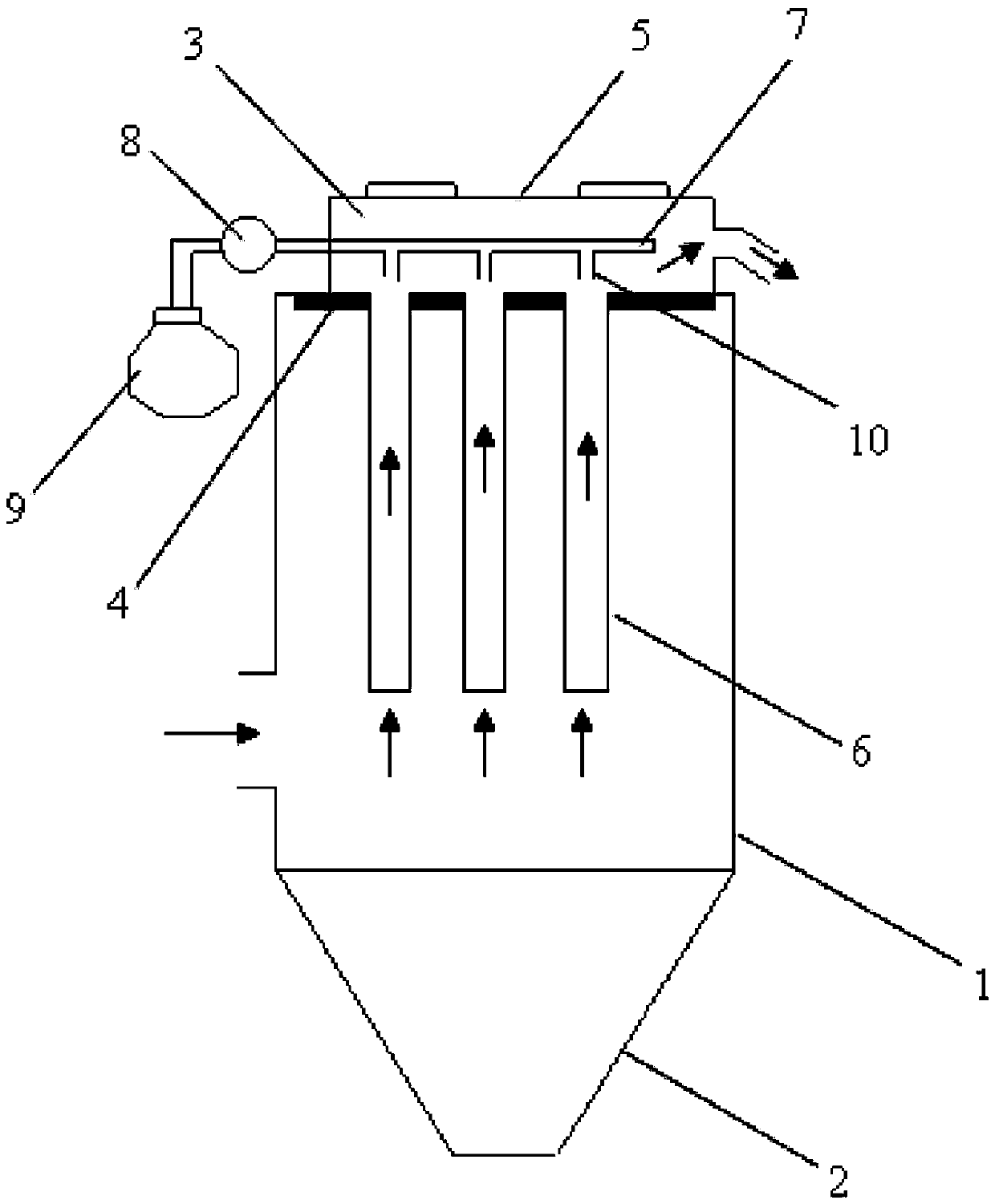

[0018] In order to make the present invention clearer, the bag-type dust collector modified by the electric dust collector of the present invention will be further described below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention and are not intended to limit the present invention.

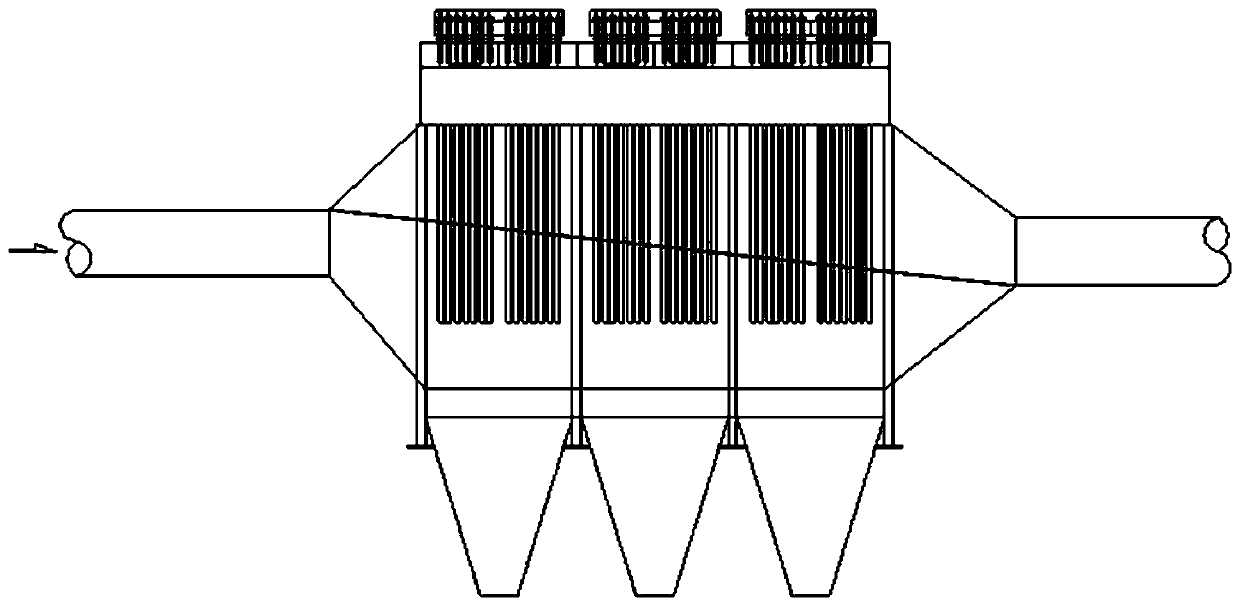

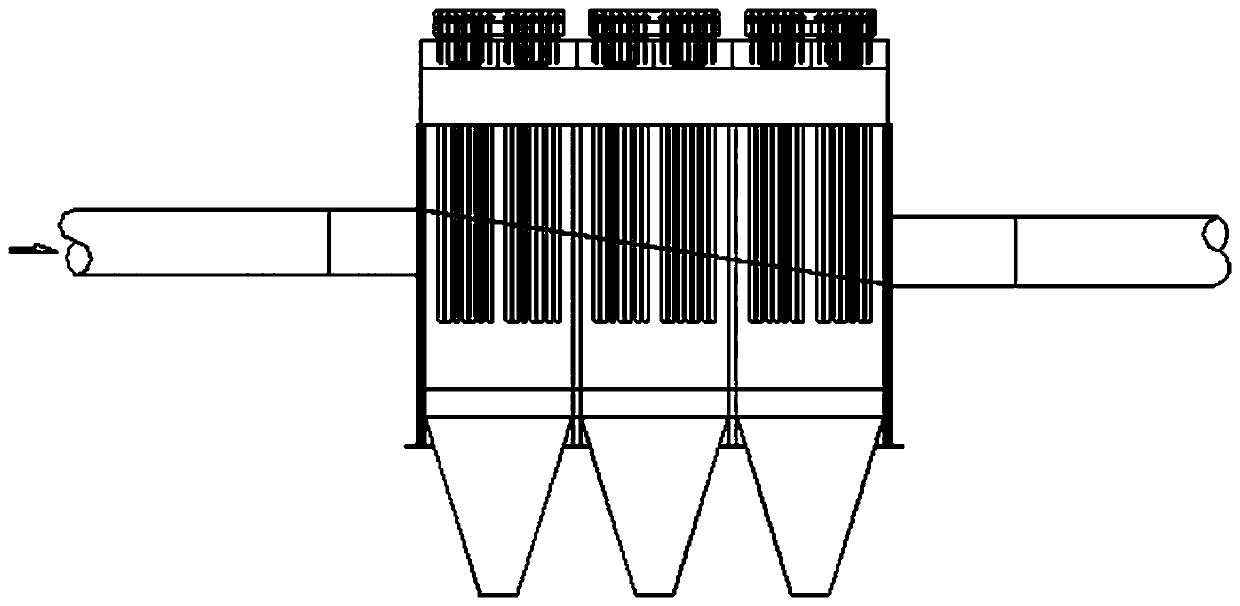

[0019] see image 3 , Figure 4 , a bag-type dust collector modified by using an electrostatic precipitator, including the foundation of the original electrostatic precipitator, an ash hopper 2, a shell 1, an inlet horn 17, and an outlet horn 18, and a cleaning system including a cleaning system is added on the upper part of the original shell 1 The air box 3 and the clean air box 3 are provided with a flower plate 4 at the lower part and a maintenance platform 5 at the top; It is erected above the flower board 4 , and a filter bag 6 is arranged below the flower board 4 , and the drainage nozzle 10 at the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com