Vegetable feeding device of sandwich production and sales machine

A technology for placing devices and sandwiches, applied in baking, filling baked goods, food science, etc., can solve the problems of increasing the work intensity of equipment maintenance personnel, poor fault tolerance and stability of the device, and uncontrollable vegetable feeding amount, so as to improve the production The effect of success rate, uniform and accurate delivery, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

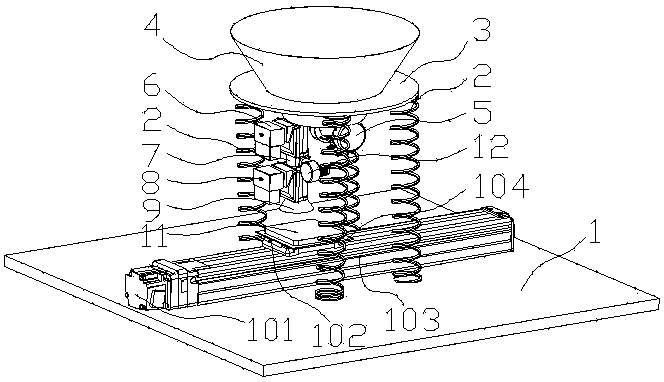

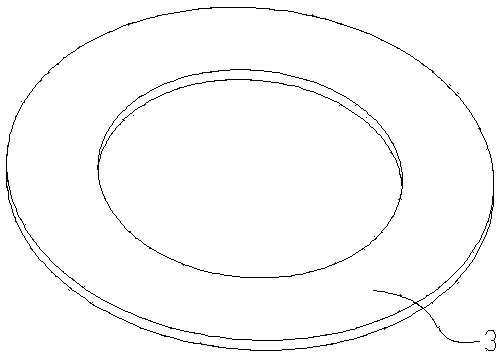

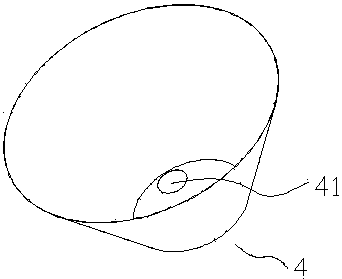

[0033] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , a new type of vegetable feeding device for a sandwich production and sales machine, which is characterized in that it includes a base plate 1, four coil springs 2 are vertically fixed on the upper surface of the base plate 1, and the four coil springs 2 are center-symmetric and distributed axially symmetrically The upper surface of the bottom plate 1; the upper ends of the four helical springs 2 are respectively fixed on the lower surface of a ring 3, the plane where the ring 3 is located is parallel to the bottom plate 1, and the center-symmetric and axisymmetric symmetry centers of the four springs 2 are aligned with the circle The straight line where the center of the ring 3 is located is perpendicular to the bottom plate 1; the circular table-shaped vegetable storage tank 4 is fixed on the ring 3, and the vegetable storage tank 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com