Heat exchange device

A heat exchange device and technology for exchanging heat, applied to electrochemical generators, electrical components, circuits, etc., can solve problems such as poor heat exchange capacity and long heat exchange time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention.

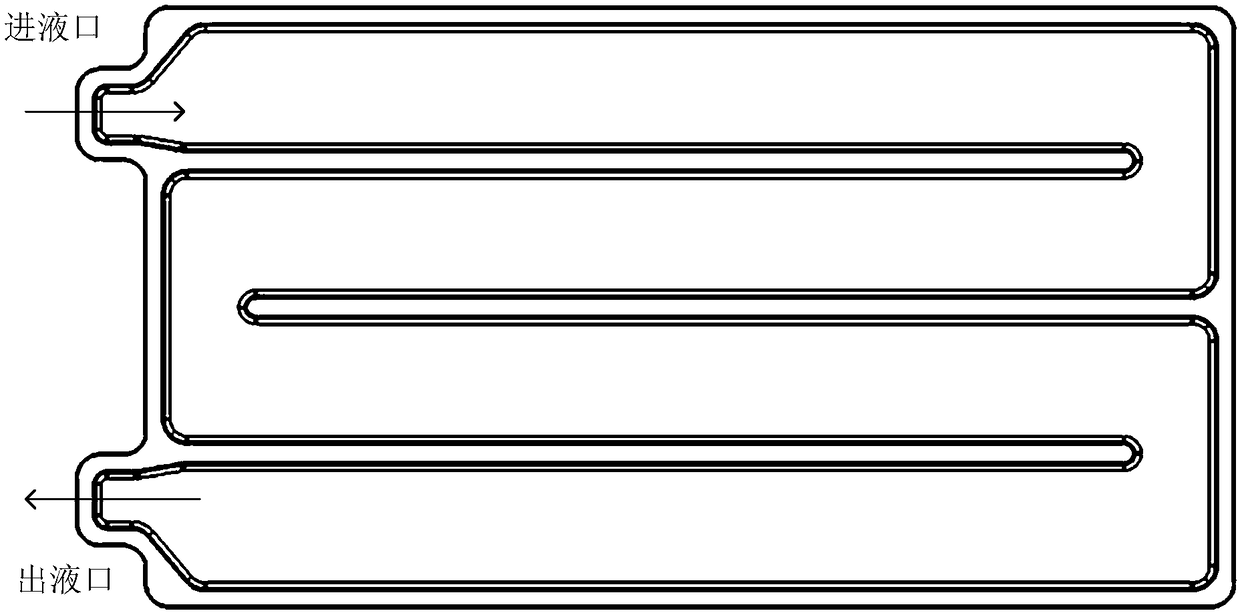

[0037] In order to solve the problems of low heat exchange efficiency and long heat exchange time in existing power battery heat exchange devices, a heat exchange device is provided in this case.

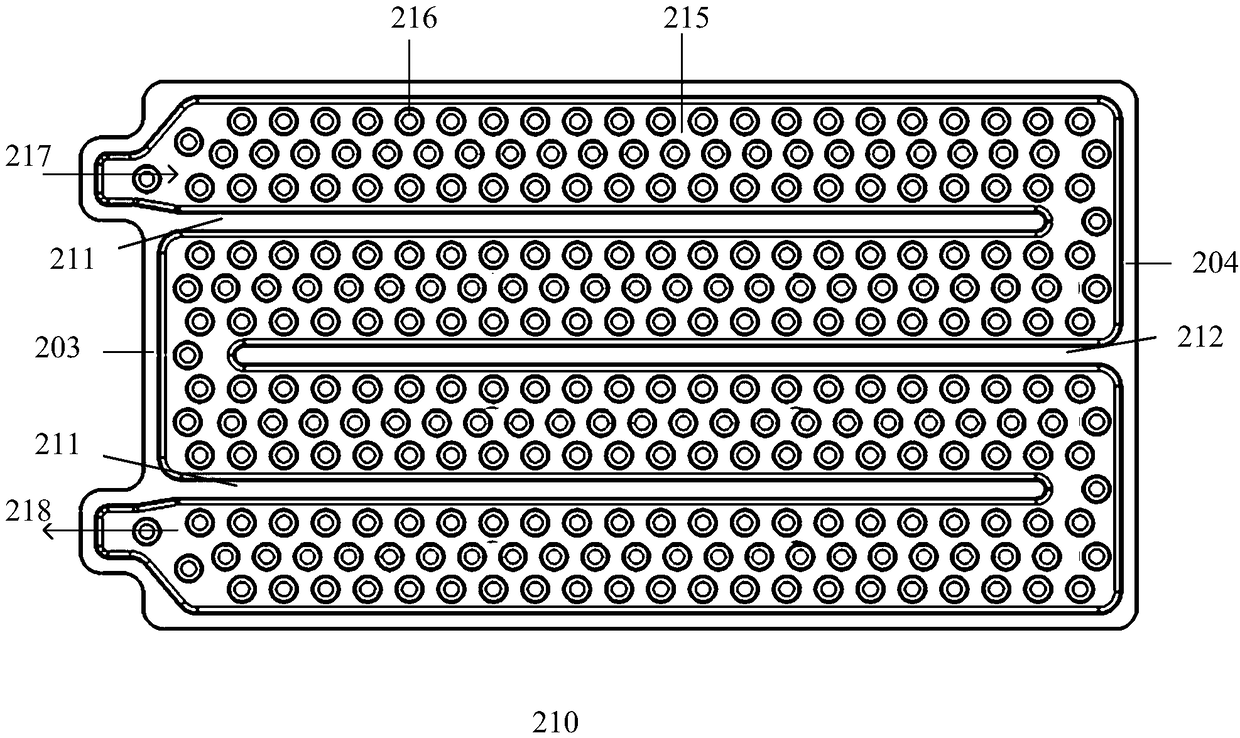

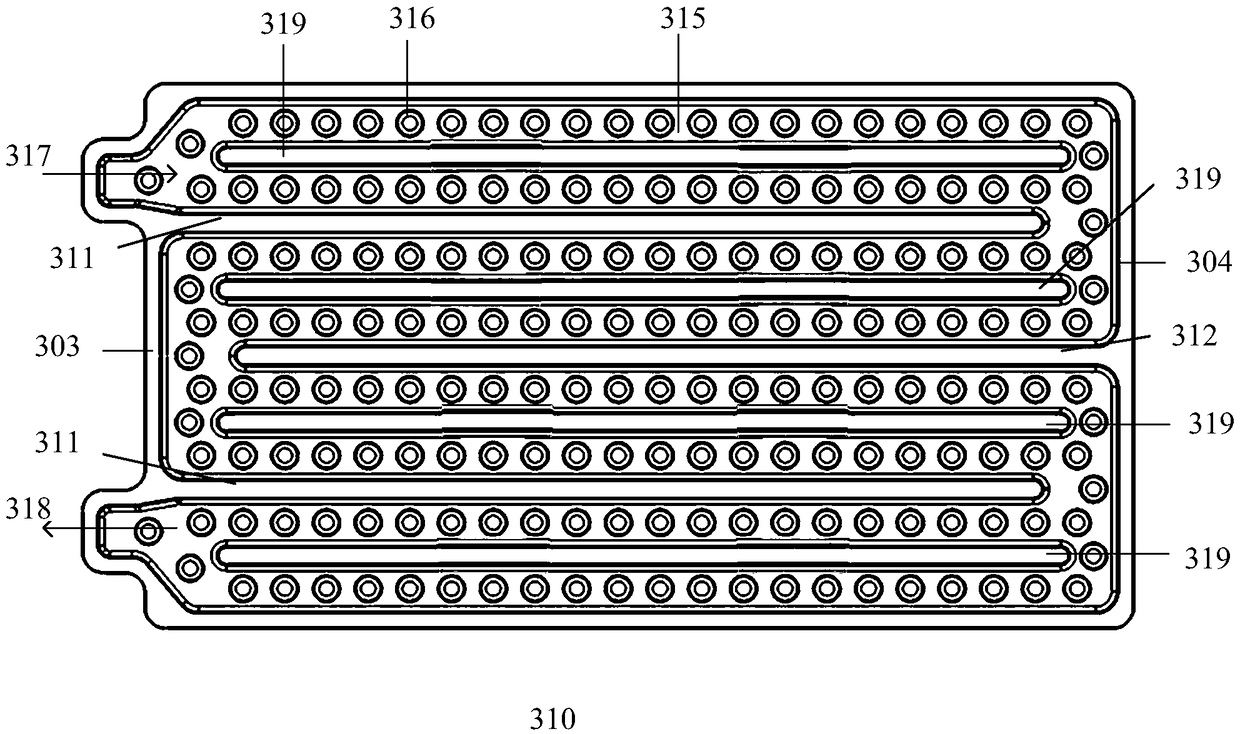

[0038] In one embodiment, as figure 2 As shown, the heat exchange device includes a first plate (not shown) and a second plate 210 .

[0039] The first plate is a metal plate, which is used to contact the power battery after being covered with heat-conducting silica gel.

[0040] The second flat plate 210 is a metal flat plate, and a concave portion is formed after stamping. When the periphery of the second flat plate 210 is welded or punched but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com