Electromagnetic test probe, electromagnetic test device and electromagnetic test method

An electromagnetic and testing signal line technology, applied in measuring devices, measuring leads/probes, components of electrical measuring instruments, etc., can solve problems such as affecting product performance, generating noise, and common mode interference of motherboards, achieving convenient operation, Noise removal, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

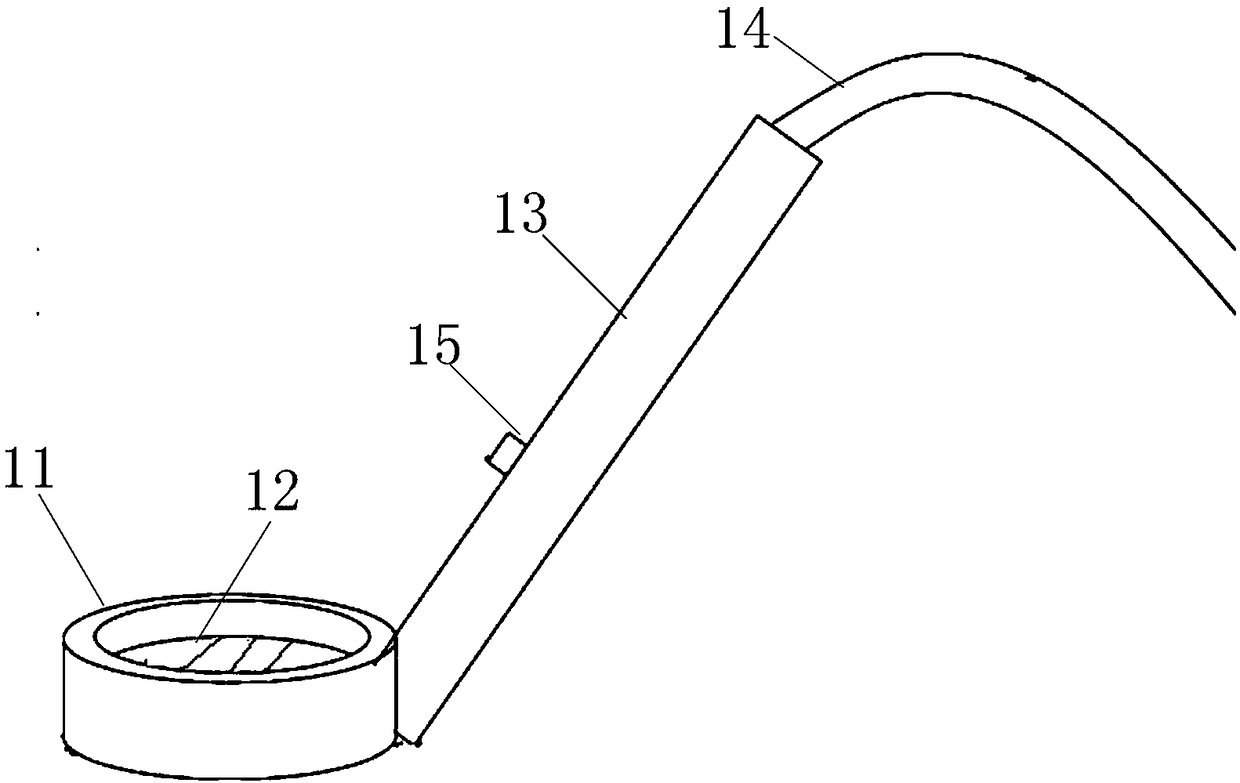

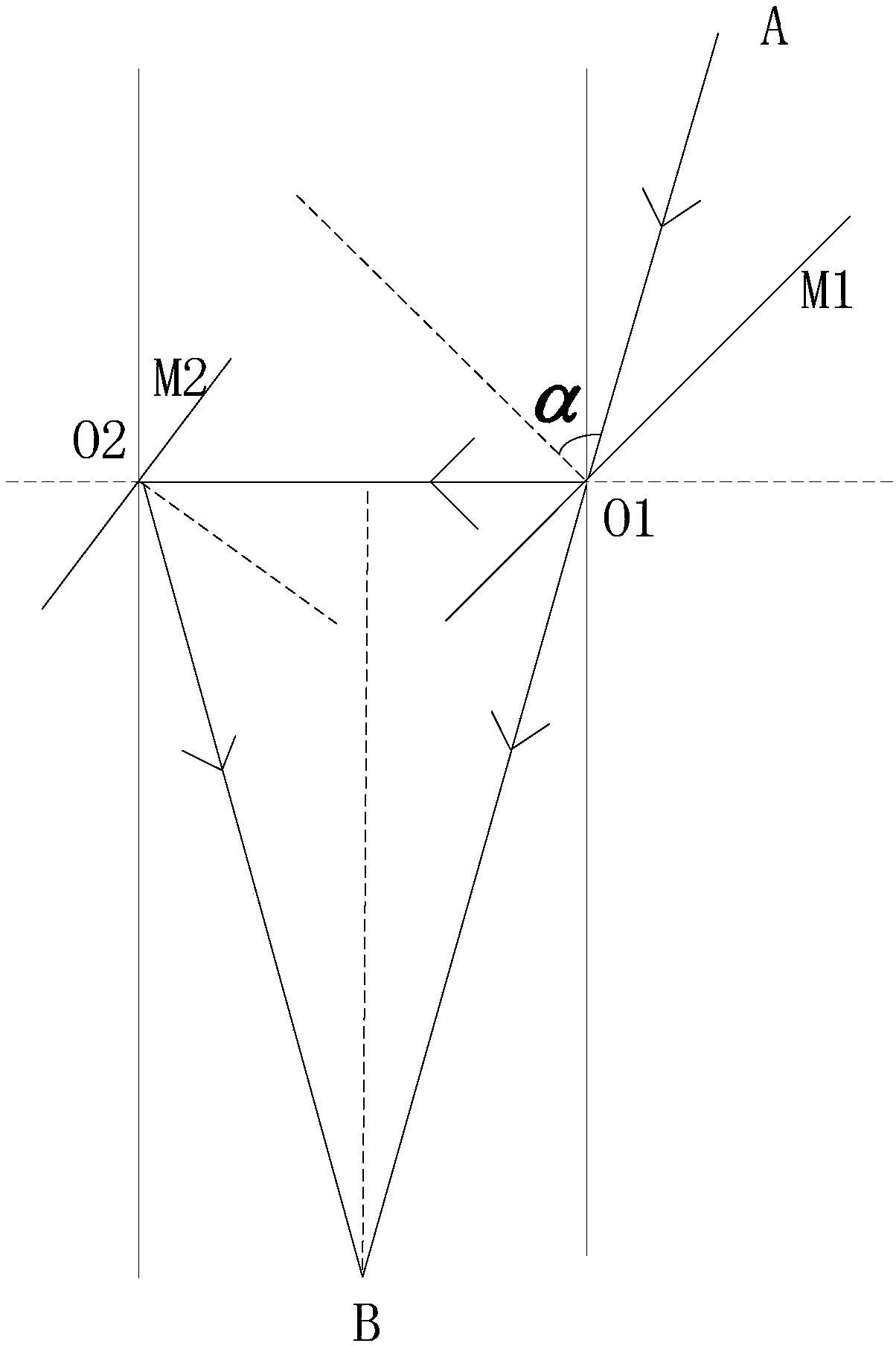

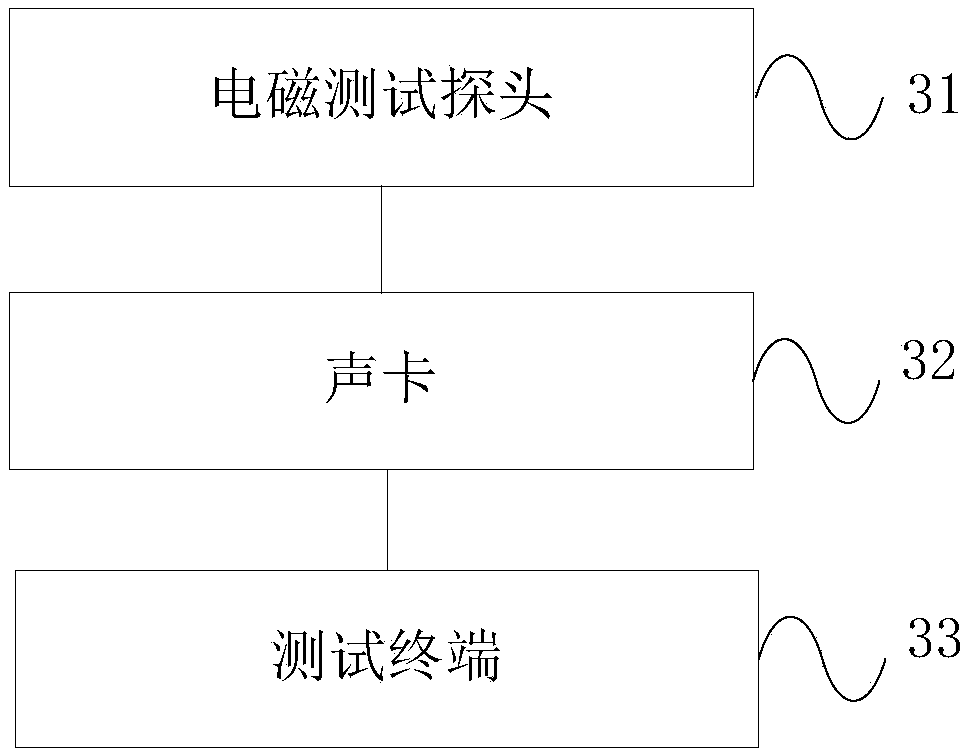

[0041] In order to solve the technical problems raised in the background technology, the inventors of the present application thought of designing an electromagnetic test probe with simple structure and convenient operation, which only includes a hollow positive cylinder and a handle, and the side walls around the positive cylinder are equipped with There are induction coils, semi-transmissive mirrors and reflectors. There is flat glass on the bottom of the positive cylinder. Laser generators and test signal lines are installed inside the handle. The tester holds the handle of the electromagnetic test probe close to the main board to be tested, and then the electromagnetic Radiation measurement, easy to operate. The present invention also designs an electromagnetic testing device comprising the above-mentioned electromagnetic testing probe and an electromagnetic testing method using the electromagnetic testing device. Through the electromagnetic testing device, the electromagne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com