Novel power head structure

A power head, a new type of technology, applied in the direction of transmission box, transmission device, large fixed members, etc., can solve the problems of shortened product life, insufficient stability, single processing, etc., to reduce the time for replacing the cutter head, and facilitate various processing , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

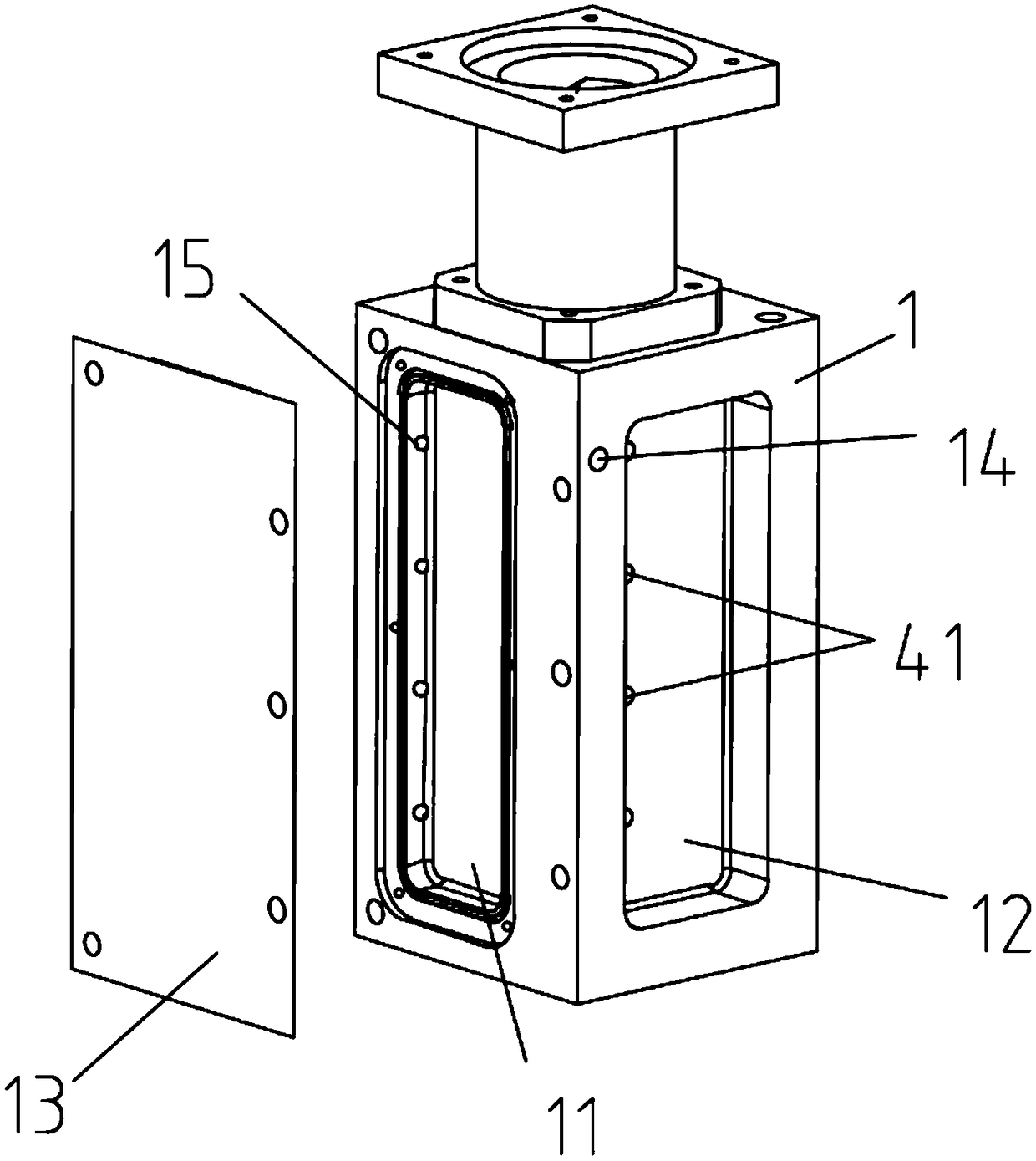

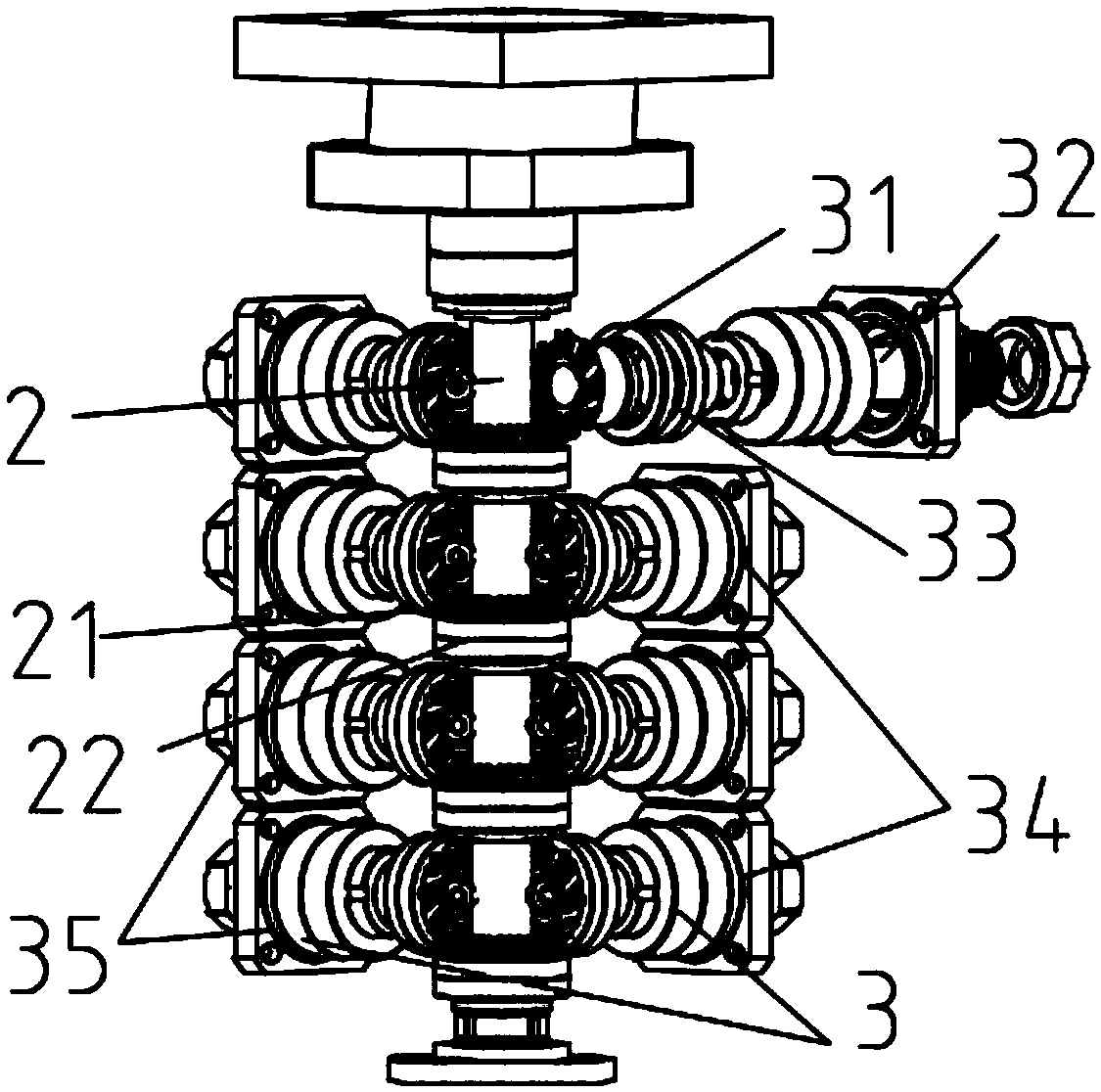

[0019] See attached Figure 1-4 , the present embodiment provides a novel power head structure, including a casing 1, a driving shaft 2 arranged in the casing 1, and a plurality of driven groups 3, and a plurality of first helical arc gears 21 are sleeved on the driving shaft 2, so that The gear hub of the first helical arc gear 21 is sleeved with a first bearing 22, and the driven group 3 includes a second helical arc gear 31, a driven shaft 32 and a second bearing 33, and the second helical arc gear 31 is sleeved on one end of the driven shaft 32, the second bearing 33 is matched with the second helical arc gear 31 and is sleeved on the gear hub of the second helical arc gear 31, the first The second helical arc gear 31 fits with the first helical arc gear 21. When the driving shaft 2 moves, the first helical arc gear 21 drives the second helical arc gear 31 to move and then drives the driven shaft to move 3 A first hollow cavity 11, a second hollow cavity 12 and a knife se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap