Method of Repairing the Outlet Edge of the Runner Blade of Francis Turbine

A technology for runner blades and blade outlets, which is applied in the field of edge modification of the outlet of Francis turbine runner blades, which can solve the problems of unable to prevent or eliminate the whistling of turbines and cracks of runner blades, so as to avoid the occurrence of blade cracks and ensure fatigue The effect of strength and simplification of the repair process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for modifying the outlet edge of a Francis turbine runner blade, comprising the following steps:

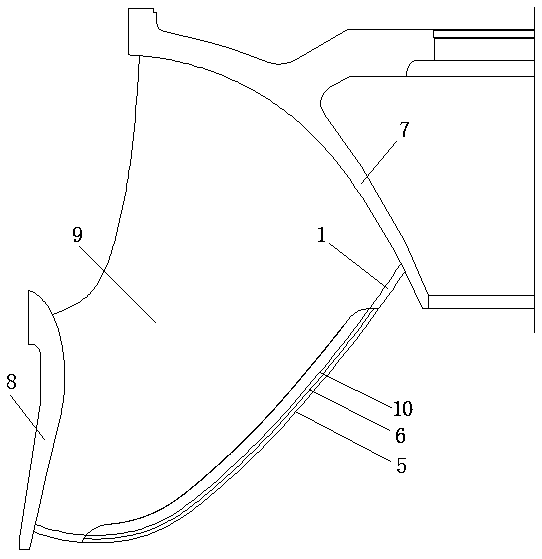

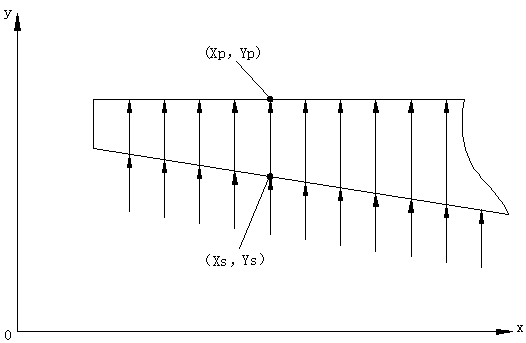

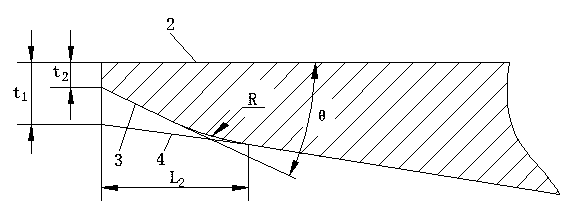

[0035]a. Cut out the airfoil of the blade and determine the repair area of the blade outlet side 1. The blade outlet side 1 includes an integrally formed upper section, a middle section and a lower section, and the length of the upper section and the lower section are both L 1 , L 1 It is 3% of the nominal diameter of the runner, the middle section is the trimmed area, the upper and lower sections are the non-profiled area, the transition between the profiled area and the non-profiled area is smooth, and the thickness of the outlet edge of the blade before the trimming is t 1 ;

[0036] b. Thickness of blade outlet edge after trimming is t 2 , the thickness of the outlet edge of the blade after modification is the thickness of the outlet edge of the blade before modification t 1 0.4 times of 0.4; the angle θ between the straight line segment in the blade fron...

Embodiment 2

[0043] A method for modifying the outlet edge of a Francis turbine runner blade, comprising the following steps:

[0044] a. Cut out the airfoil of the blade and determine the repair area of the blade outlet side 1. The blade outlet side 1 includes an integrally formed upper section, a middle section and a lower section, and the length of the upper section and the lower section are both L 1 , L 1 It is 3.5% of the nominal diameter of the runner, the middle section is the trimmed area, the upper and lower sections are the non-modified area, the transition between the trimmed area and the non-modified area is smooth, and the thickness of the outlet edge of the blade before the trimming is t 1 ;

[0045] b. Thickness of blade outlet edge after trimming is t 2 , the thickness of the outlet edge of the blade after modification is the thickness of the outlet edge of the blade before modification t 1 0.45 times of 0.45 times; the angle θ between the straight line segment in the ...

Embodiment 3

[0053] A method for modifying the outlet edge of a Francis turbine runner blade, comprising the following steps:

[0054] a. Cut out the airfoil of the blade and determine the repair area of the blade outlet side 1. The blade outlet side 1 includes an integrally formed upper section, a middle section and a lower section, and the length of the upper section and the lower section are both L 1 , L 1 It is 4% of the nominal diameter of the runner. The middle section is the trimmed area, and the upper and lower sections are non-profiled areas. There is a smooth transition between the trimmed area and the non-profiled area. The thickness of the outlet edge of the blade before the trimming is t 1 ;

[0055] b. Thickness of blade outlet edge after trimming is t 2 , the thickness of the outlet edge of the blade after modification is the thickness of the outlet edge of the blade before modification t 1 0.5 times of ; the angle θ between the straight line segment in the blade front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com