Damage patching and repairing method based on memory alloy and for expandable tubular

A memory alloy and repair method technology, which is applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of easy occurrence of downhole accidents, low construction efficiency, complex mechanism, etc., and achieves convenient preparation, improved success rate, and broad application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

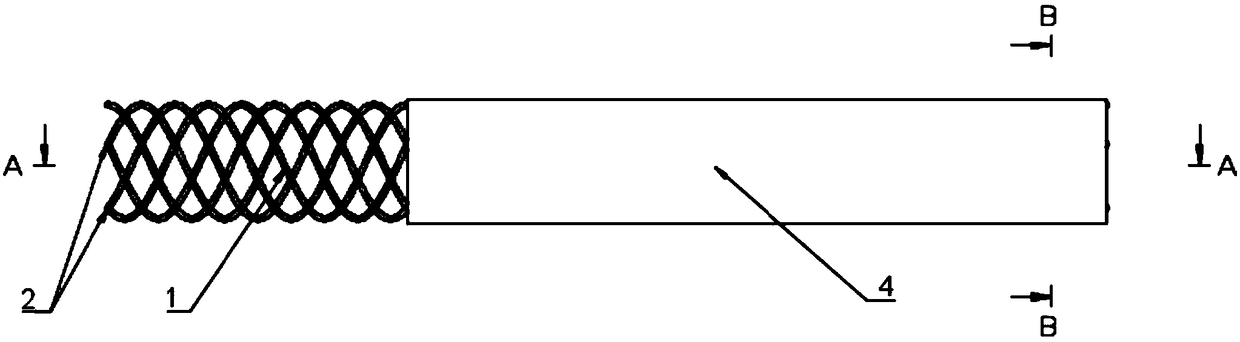

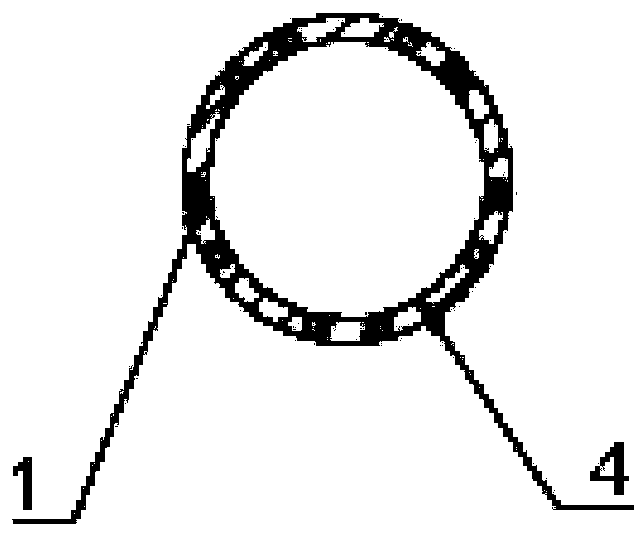

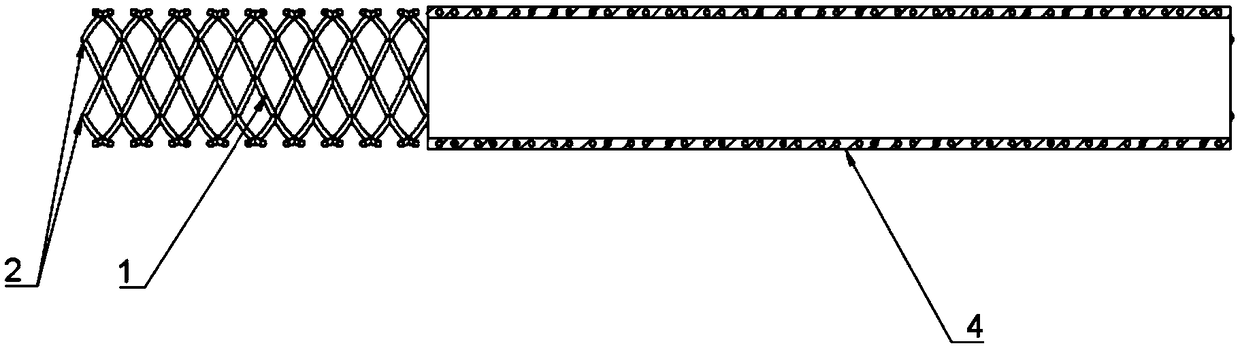

[0049] 1) Select 24 Ti-Ni memory alloy wires with a diameter of 4 mm to make a 125 mm outer diameter and a 9 mm wall thickness memory alloy expansion sleeve damage compensation tool, wherein the memory alloy wire mesh adopts a Ti-Ni-based shape memory alloy Made of silk, it has a good shape memory effect. The elastic sealing material tube 4 is made of cyanide-butadiene rubber, which has a large elastic deformation capacity and high-pressure resistance;

[0050] 2) Accurately measure the location and internal dimensions of the damaged casing section with an outer diameter of 140 mm and a wall thickness of 7.72 mm, and use casing milling or shaping tools to reshape and clean the inside of the casing;

[0051] 3) Put the memory alloy expansion sleeve damage compensation tool on the ground in a liquid nitrogen box (temperature is less than minus 20 degrees), and apply uniform stress on both ends to elongate the memory alloy expansion sleeve damage compensation tool, so that the mem...

Embodiment 2

[0057] 1) Select 223 mm outer diameter and 19 mm wall thickness memory alloy expansion sleeve damage compensation tool made of 16 Ti-Ni-V memory alloy wires with a diameter of 9 mm, in which the memory alloy wire mesh is made of Ti-Ni-V The shape memory alloy wire is woven, which has a good shape memory effect. The elastic sealing material tube is made of fluorobutane rubber, which has a large elastic deformation capacity and high temperature and high pressure resistance;

[0058] 2) Accurately measure the position and internal dimensions of the casing damaged section with an outer diameter of 244.5 mm and a wall thickness of 12 mm, and use casing milling or shaping tools to reshape and clean the inside of the casing;

[0059] 3) Put the memory alloy expansion sleeve damage compensation tool on the ground in a low-temperature cold box (temperature is less than zero), and apply uniform stress on both ends to elongate the memory alloy expansion sleeve damage compensation tool, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com