Fertility improving type thermal desorption soil remediation equipment and method

A soil remediation and thermal desorption technology, applied in the field of fertilizer-enhancing thermal desorption soil remediation equipment, can solve the problems of easy sandification, uneven heating, loss of nutrients, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

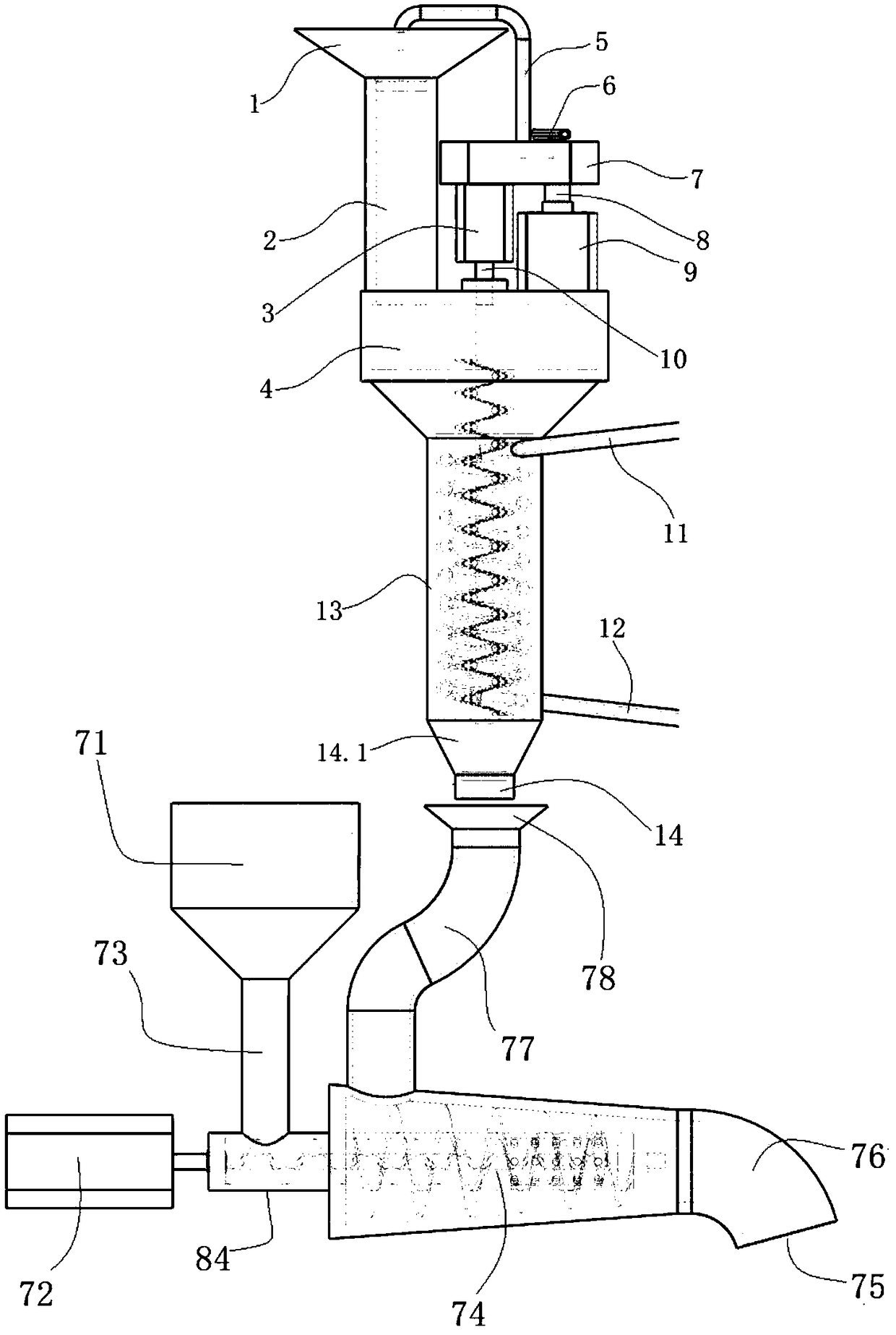

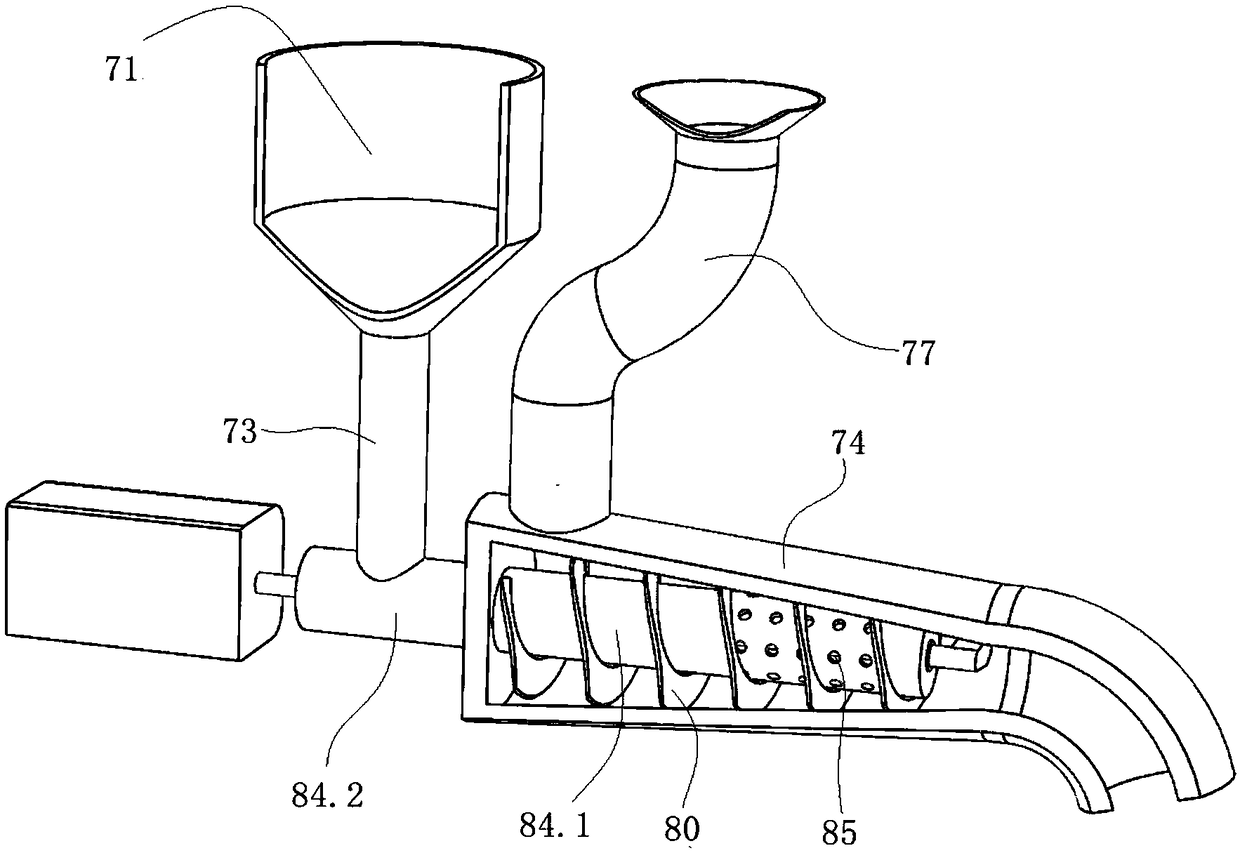

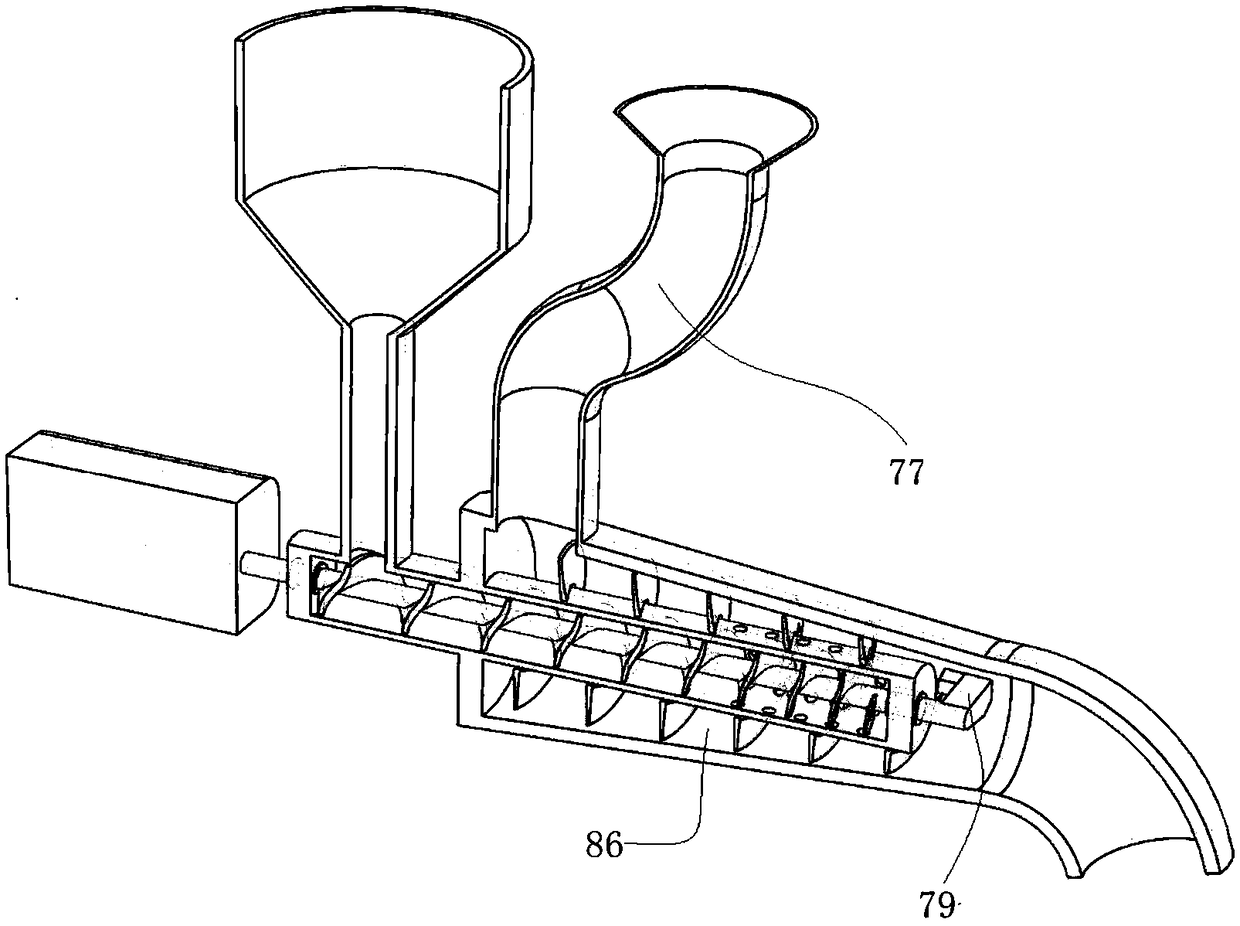

[0038] as attached Figures 1 to 10 A kind of fertilization type thermal desorption soil remediation equipment shown, comprises dung sludge tower 71, soil thermal desorption equipment, dung soil mixing fertilization device; The dung sludge discharge end of described dung sludge tower 71 is connected with described dung soil mixing The dung sludge feed end of the fertilization device, the thermal desorption soil discharge end of the soil thermal desorption device is connected to the soil source feed end of the dung soil mixing fertilization device.

[0039] The device for mixing and fertilizing manure and soil comprises a manure sludge transmission extruding pipe 84, and a columnar manure sludge extruding channel 87 is arranged in the manure sludge conveying extruding pipe 84, and the inside of the columnar manure sludge extruding channel 87 is coaxial The core rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com