Sand production device

A technology of sand making machine and sand and gravel material, applied in the direction of grain processing, etc., can solve the problems of difficult sand and gravel dust removal, high powder content of sand and gravel, unable to meet production requirements, etc., so as to improve the powder removal efficiency and increase the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

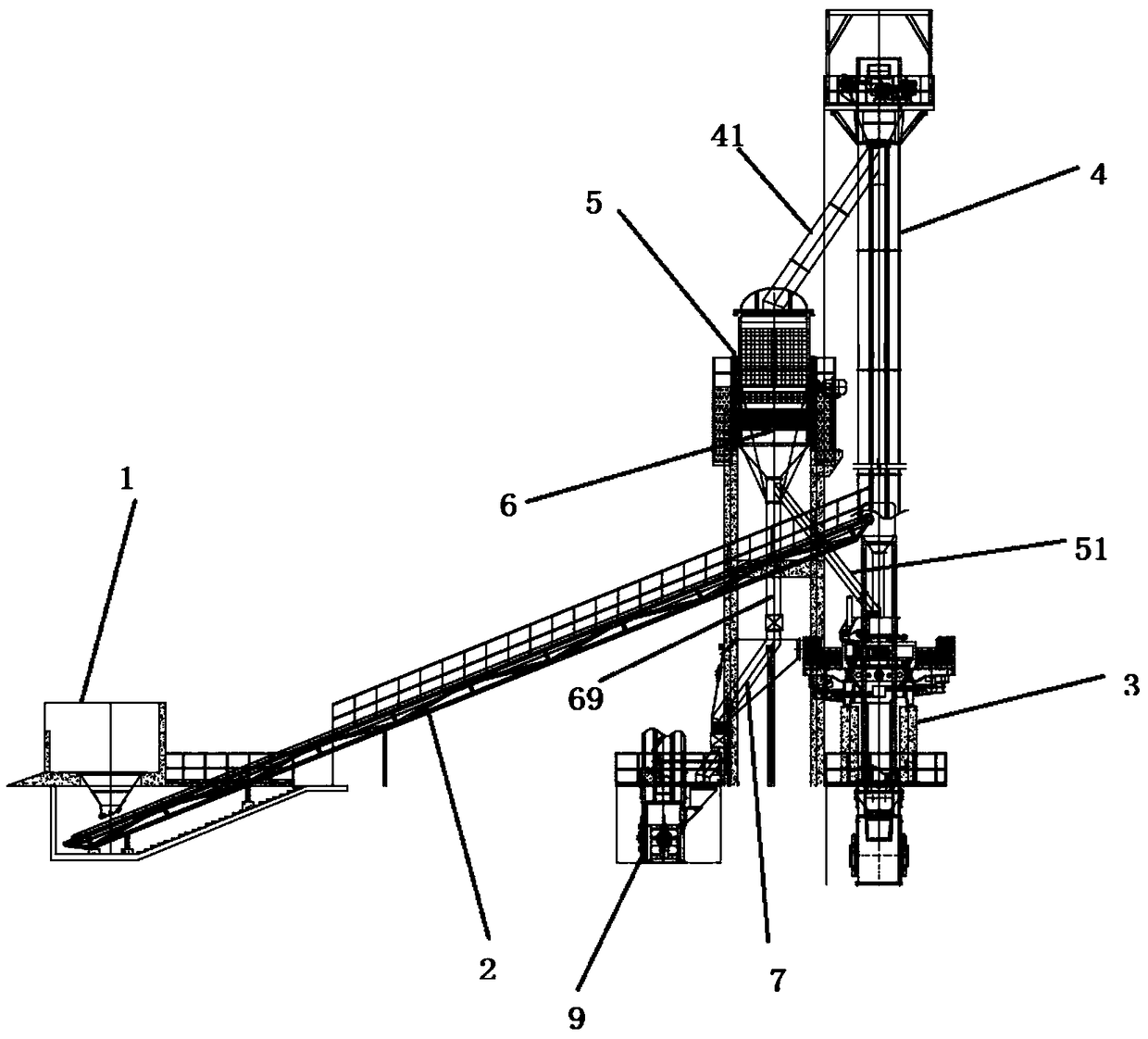

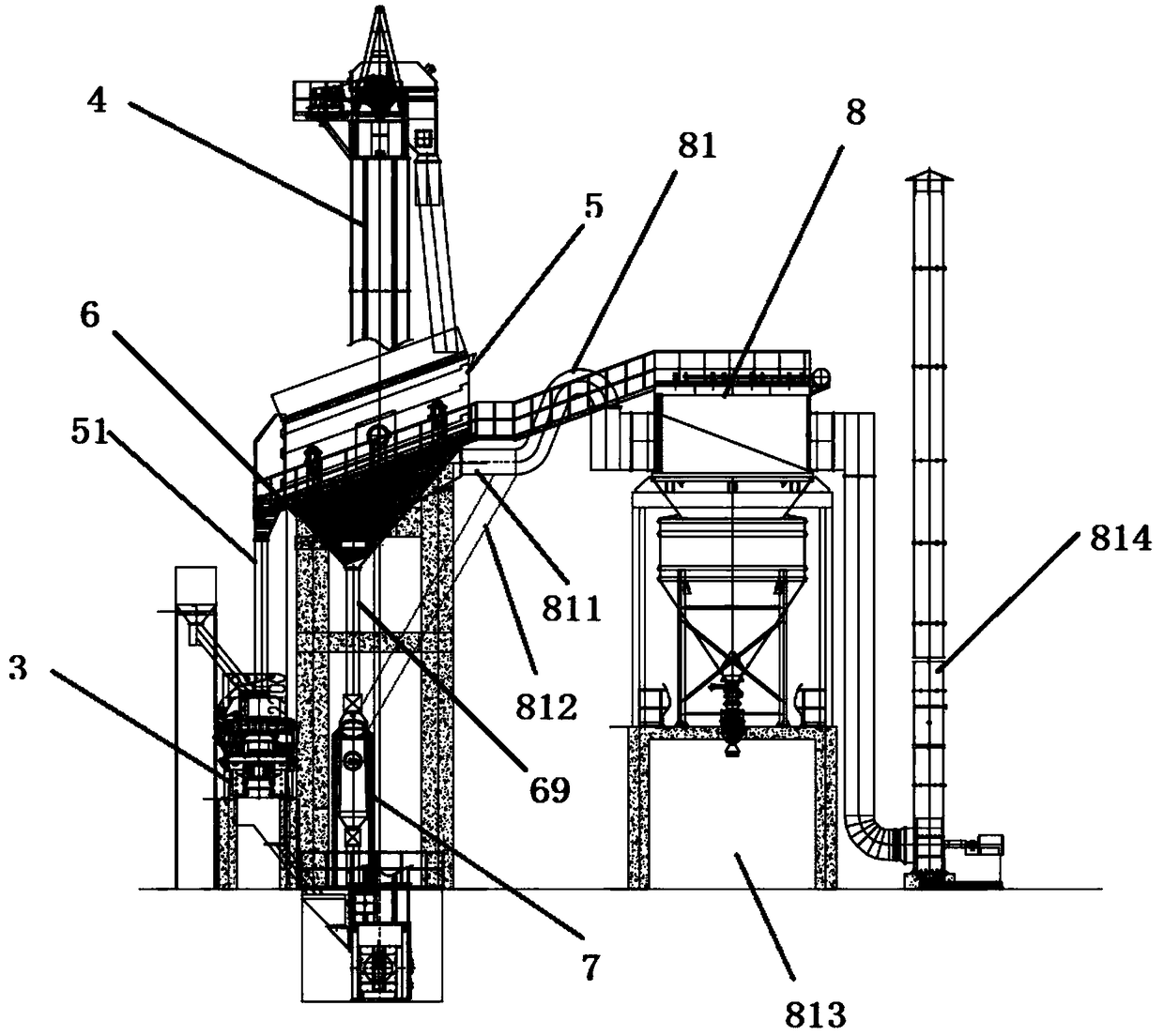

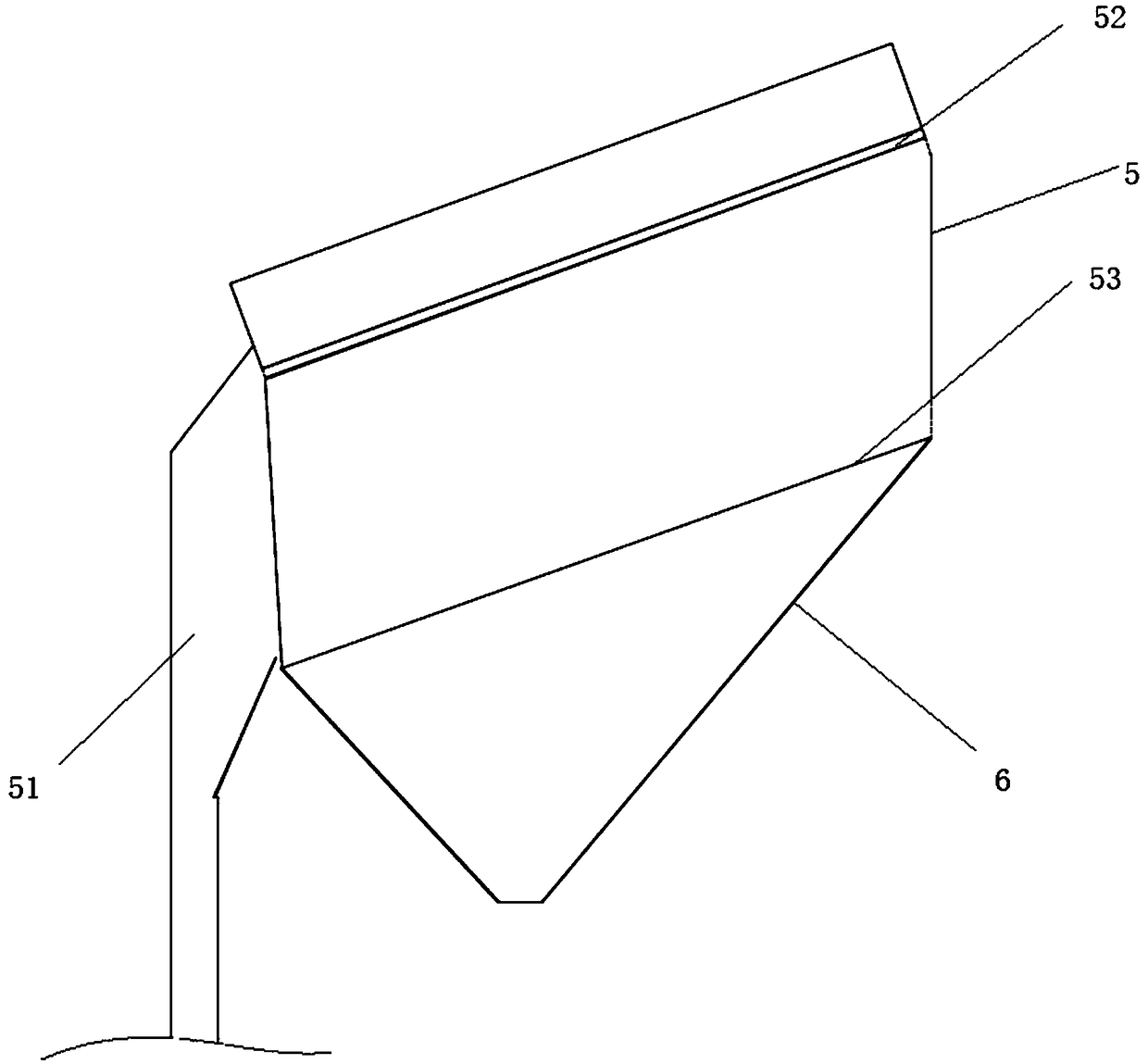

[0038] see Figure 1 to Figure 4 , a sand making device according to a preferred embodiment of the present invention includes a sand hopper 1, a conveyor belt 2, a sand making machine 3, a hoist 4, a vibrating screen 5, a powder removal hopper 6, a powerless powder removal machine 7, Dust collector 8 and storage machine 9;

[0039] Among them, the conveyor belt 2 is used to transport the ore material dropped from the sand and gravel hopper 1 to the sand making machine 3;

[0040] The sand making machine 3 is used for crushing the ore material, and the crushed ore material is transported to the vibrating screen 5 through the elevator 4;

[0041] The vibrating screen 5 is a two-stage screen, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com