A device and method for removing volatile organic compounds in emulsion

An organic compound and volatile technology, applied in the field of green petrochemical industry, can solve the problems that affect the production capacity of equipment, lack of reference, and a large number of skinning, so as to reduce the risk of foaming, high processing efficiency, and reduce the effect of skinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

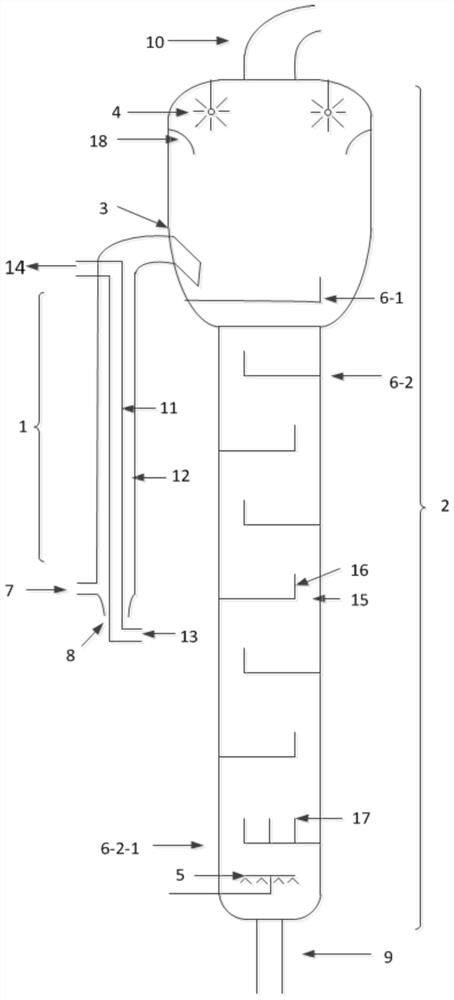

[0055] A device for removing volatile organic compounds in emulsion (such as figure 1 shown), including vapor-liquid mixer 1 and de-VOC tower 2;

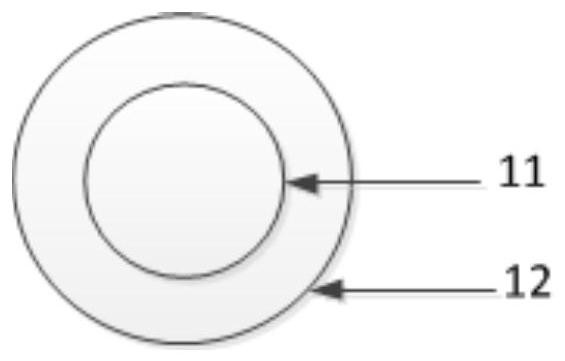

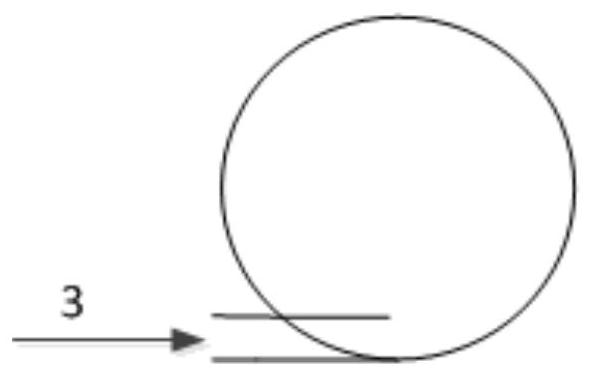

[0056] The gas-liquid mixer 1 is a multi-layer casing structure (such as figure 2 As shown), it includes an inner film sleeve 11 and an outer membrane sleeve 12 coaxially arranged; the inner membrane sleeve 11 is provided with a hot water inlet 13 and a hot water outlet 14; the outer membrane sleeve 12 is a vapor-liquid mixing member, and its The bottom is provided with two inlets, respectively the emulsion inlet 7 and the water vapor inlet 8, and the outlet of the upper part, that is, the outlet of the vapor-liquid mixer 1, is connected with the feed port 3 positioned at the top of the VOC removal tower 2; the feed port 3 (such as image 3 Shown) is located at the 1 / 4 height position of the upper part of the tower body, tangentially downward 10° along the inner wall of the tower.

[0057] The tower body of the VOC removal tower ...

Embodiment 2

[0063] A device for removing volatile organic compounds in emulsion, the difference from Example 1 is:

[0064] Vapor-liquid mixer 1 (such as Figure 6 Shown) is a tubular structure with multi-layer orifice plate 19, the bottom is provided with two inlets, respectively emulsion inlet 7 and water vapor inlet 8, the upper outlet is the outlet of the vapor-liquid mixer 1 and the VOC removal tower 2 The feeding port 3 on the top is connected; the number of holes in the bottom orifice plate 19-1 is 1, and the ratio of the hole area to the cross-sectional area of the orifice plate is 0.8:1; the number of holes in the remaining orifice plates 19-2 is 6, and the hole The ratio of the area to the cross-sectional area of the orifice plate is 0.6:1.

[0065] The inner diameter ratio of the upper part of the VOC removal tower body to the lower part is 2:1; there are 7 layers of sieve plate 6 in the VOC removal tower 1, and the aperture is 2.2 cm; the height of the overflow weir 16 is...

Embodiment 3

[0067] A method for removing volatile organic compounds in emulsion: adopt embodiment 1 device (removing VOC tower 2 size ), the steps include:

[0068] 1) 20,000kg of styrene-acrylic emulsion (flow rate of 5000kg / h, viscosity of 800mpa·S) and 85°C saturated water vapor (flow rate of 900kg / h) respectively enter the outer membrane casing of the vapor-liquid mixer 1 through the emulsion inlet 7 and the water vapor inlet 8 Mix in the tube 12 to form a uniform vapor-liquid mixture; at the same time, hot water circulates in the inner membrane casing 11 through the hot water inlet 13 and the hot water outlet 14, and the hot water circulation temperature is 52°C;

[0069] 2) In the de-VOC tower 2, the vacuum degree is 7Kpa through the vacuum pumping port 10, and the pumping capacity is 3000m3 / h. The baffle plate 18 blocks the foam in the tower from entering the vacuum system along the vacuum pumping line; the vapor-liquid mixture is fed from the upper part of the de-VOC tower 2 Por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com