Automatic discharge device of lithium battery

An automatic discharge and lithium battery technology, applied in secondary battery charging/discharging, battery recycling, secondary battery repair/maintenance, etc., can solve the problem of low efficiency and achieve the effect of cooling water circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

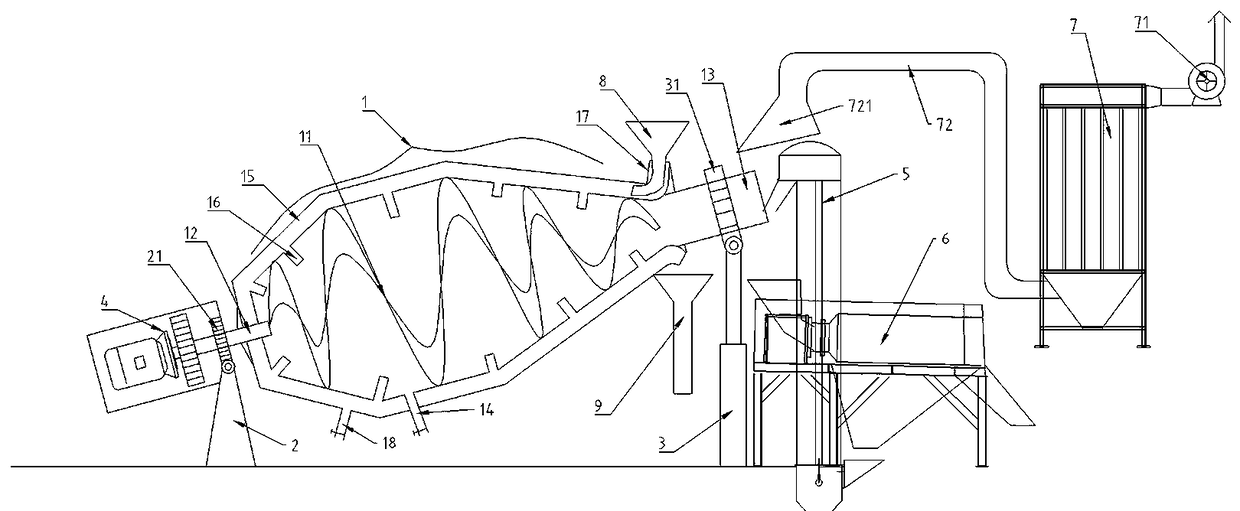

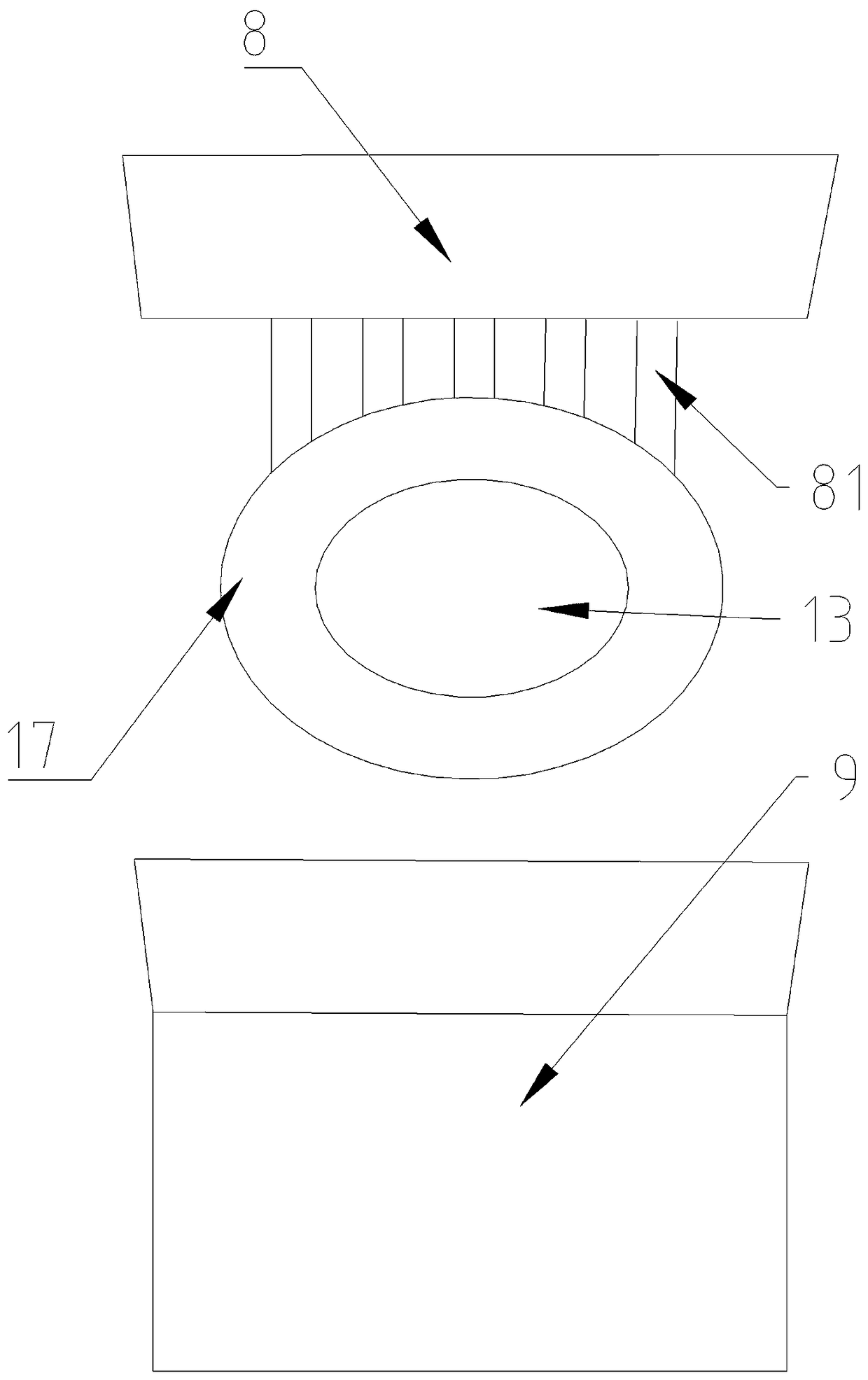

[0026] The specific embodiment of the present invention sees Figure 1-3 :

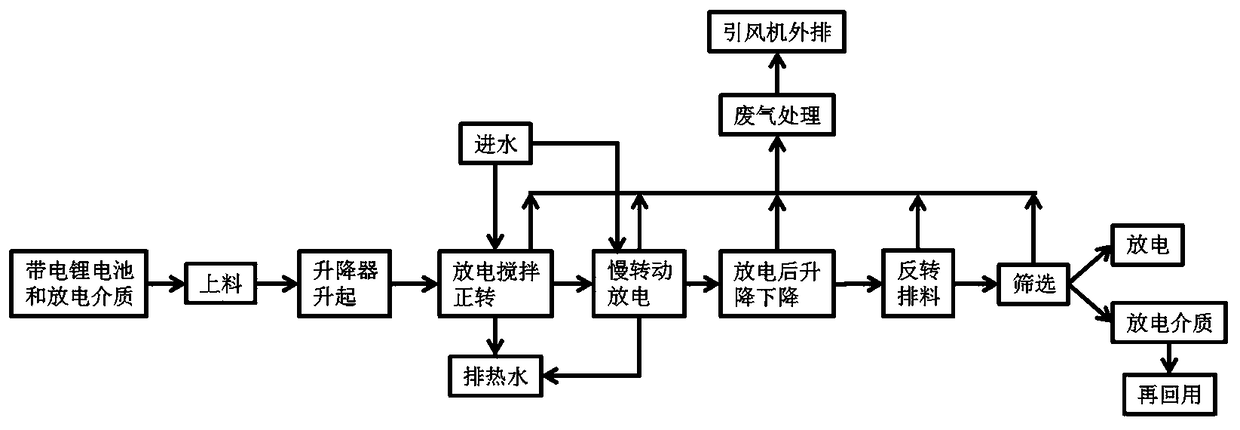

[0027] In the discharge device of the present invention, a discharge medium needs to be added. The discharge medium can be solid or liquid. The solid discharge medium includes metal medium (such as metal particle powder, copper particle powder, iron particle powder, aluminum particle powder, etc.) and non-metallic discharge medium. (Carbon powder, graphite powder, mica powder and other conductive powders); liquid discharge medium is conductive liquid (such as sodium sulfate liquid, sodium carbonate liquid, potassium carbonate liquid, graphite powder slurry, carbon powder slurry, metal powder slurry, etc.), As a liquid discharge medium, try to avoid using salt and sodium chloride as the discharge liquid. Because sodium chloride is highly corrosive to metal aluminum, it will corrode the aluminum in the lithium battery, and when the high-energy battery is discharged, the water is electrolyzed into hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com