LMR microstructure optical fiber

A microstructure fiber and fiber core technology, applied in cladding fibers, light guides, optics, etc., can solve difficulties and other problems, and achieve the effects of easy acquisition, real-time monitoring, and favorable filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

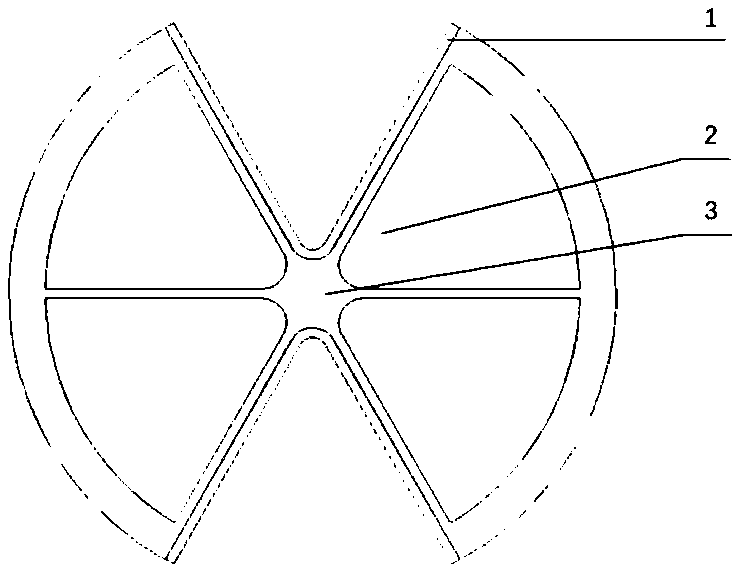

[0035] Such as figure 1As shown, the present invention provides a kind of LMR microstructure optical fiber, which adopts the core cladding structure, the outer diameter of the core is 125um, the material is quartz glass, there is no air hole in the center of the core, and the core diameter is 15um. There are six fan-shaped air holes of the same size arranged in a regular hexagon in the cladding, the diameter of the fan-shaped air holes is 100um, the distance between adjacent fan-shaped air holes is 2um, and its refractive index is 1, which will be relative to The roughly symmetrical fan-shaped air hole in the center of the fiber core 3 is opened to communicate with the outside world. Therefore, the fiber optic probe can be directly put into the fluid to be measured for filling, and the light transmitted in the fiber core is easier to pass through the film and the fluid. Loss mode resonance is carried out, so that the resonance trough is more obvious, and the accuracy of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com