Temperature control and pressure control sample stage and temperature and pressure control system

A technology of sample stage and sample tank, which is applied in the field of temperature and pressure control sample stage and temperature and pressure control system, which can solve the problems of rare pressure controllable sample stage and failure to meet the temperature requirements, so as to increase the ability of low temperature resistance and good regulation Capabilities, effects of filling inadequacies and vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

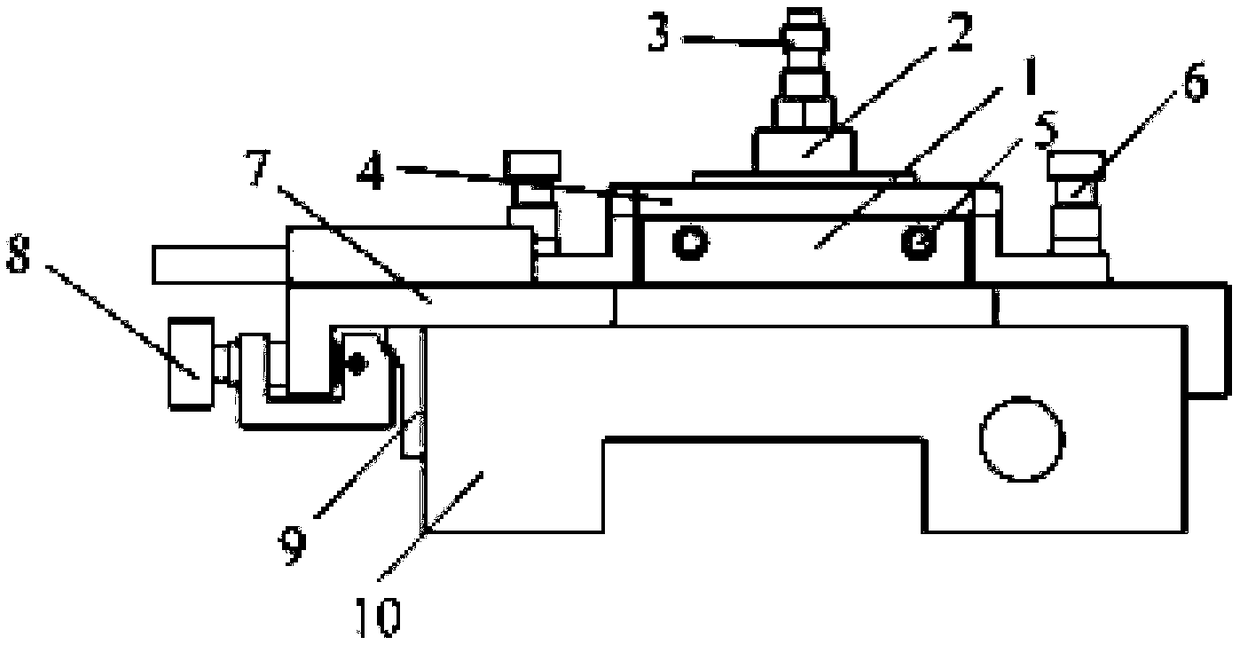

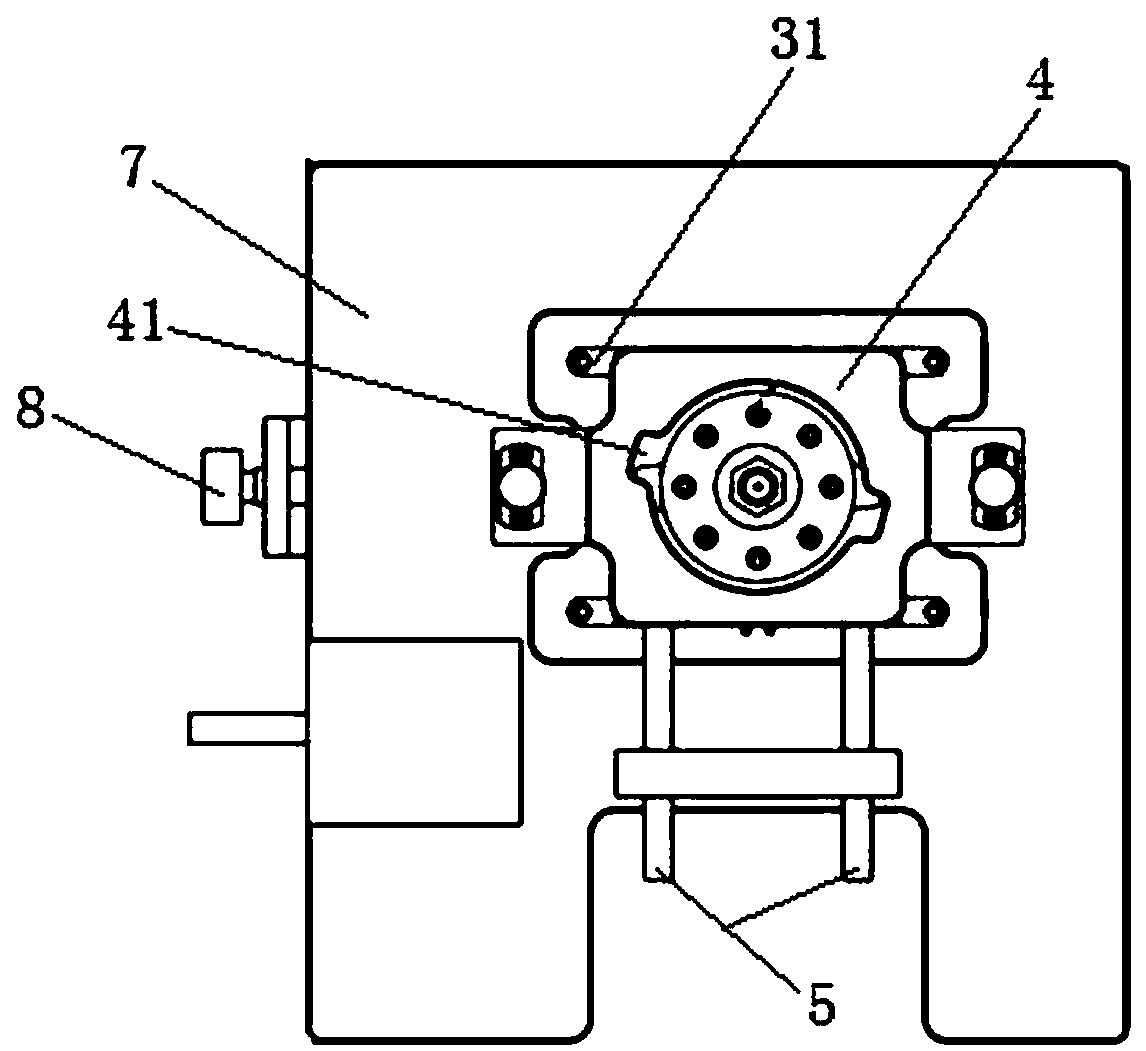

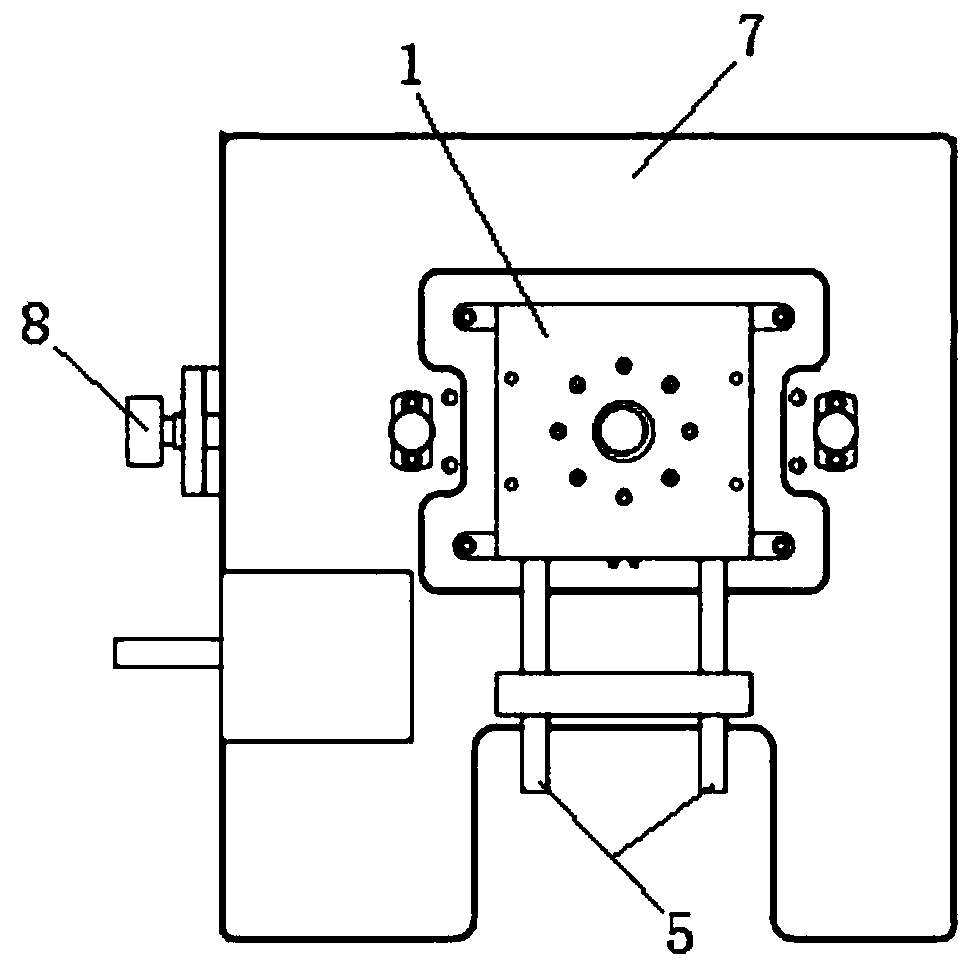

[0023] Please refer to figure 1 , the embodiment of the present invention provides a temperature-controlled and pressure-controlled sample stage, which can be used for testing the morphology, electrical, magnetic and mechanical properties of gas hydrates, and can also be used for other solid-state non-conductors, organic solids, polymers, etc. It can test the morphological, electrical, magnetic and mechanical properties of substances and biological macromolecules. It includes a pressure cover 2, a heat conductor 1 and a microscope stage 10 arranged in sequence from top to bottom.

[0024] Please refer to figure 1 with Figure 4 , the heat conductor 1 is square or circular. In this embodiment, a square is used as an example for illustration. A sample t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com