Method for measuring flushing performance of base layer by lateral distribution rutmeter

A technology of lateral distribution and rutting, which is applied in the direction of removing certain component weighing, measuring devices, testing wear resistance, etc., can solve problems such as erosion damage, and achieve a simple, easy-to-operate method, obvious economic and social benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

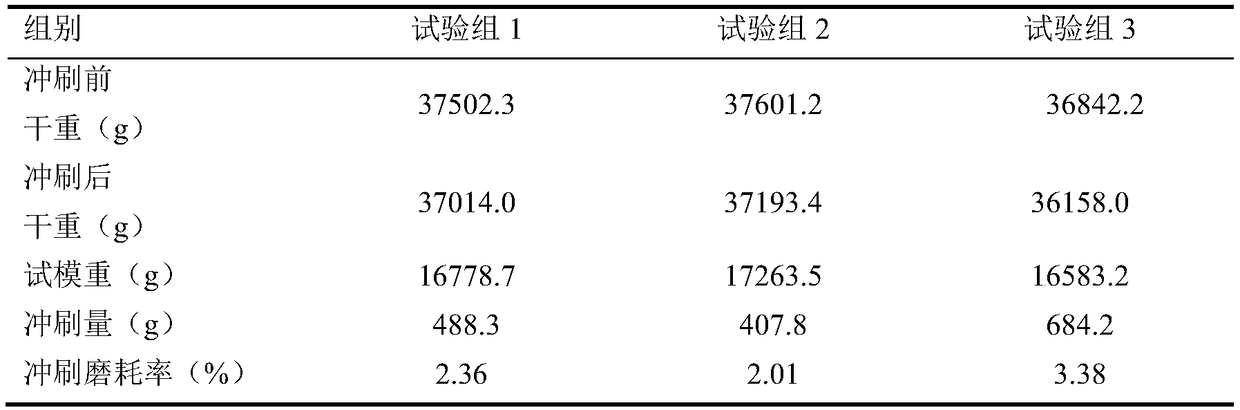

[0065] In order to verify the method, the experimental group used multiple comparison test groups of different graded mixtures for experimental verification. According to the cement-stabilized gravel gradation recommended in the "Technical Rules for Road Pavement Base Construction" JTG F20-2015, C-C- 1. C-C-2, C-C-3 three water-stabilized crushed stone base gradations are used as test groups 1-3, and then verified according to the above steps. The test results are shown in Table 1.

[0066] Table 1 Scouring wear test results

[0067]

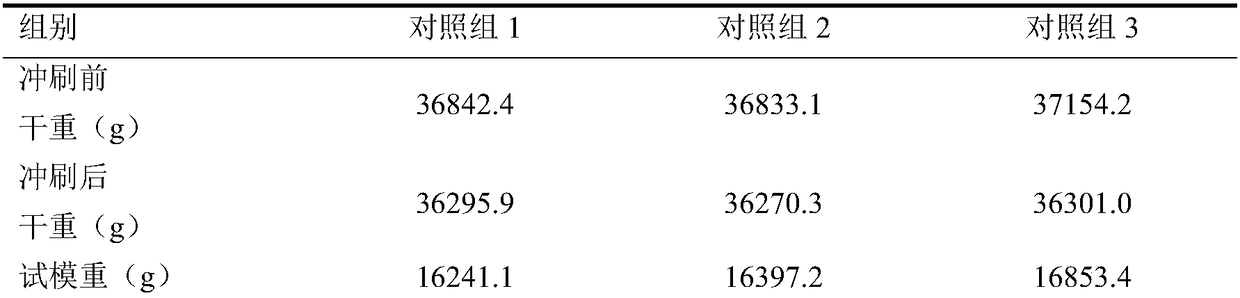

[0068] As a control group, the test method of T 0860-2009 anti-erosion test method of inorganic binder stabilized materials in the JTG E51-2009 specification of "Test Regulations for Inorganic Binder Stable Materials in Highway Engineering" was used to carry out the control group test, and then verified according to the above steps. The test results As in Table 2. The control group uses the same graded mixture control group 1-3 as the test g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com