Multi-source complementary collecting-distributing heat source tower heat pump system

A heat source tower heat pump and distributed technology, applied in heat pumps, air conditioning systems, heating methods, etc., can solve problems such as insufficient heating demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

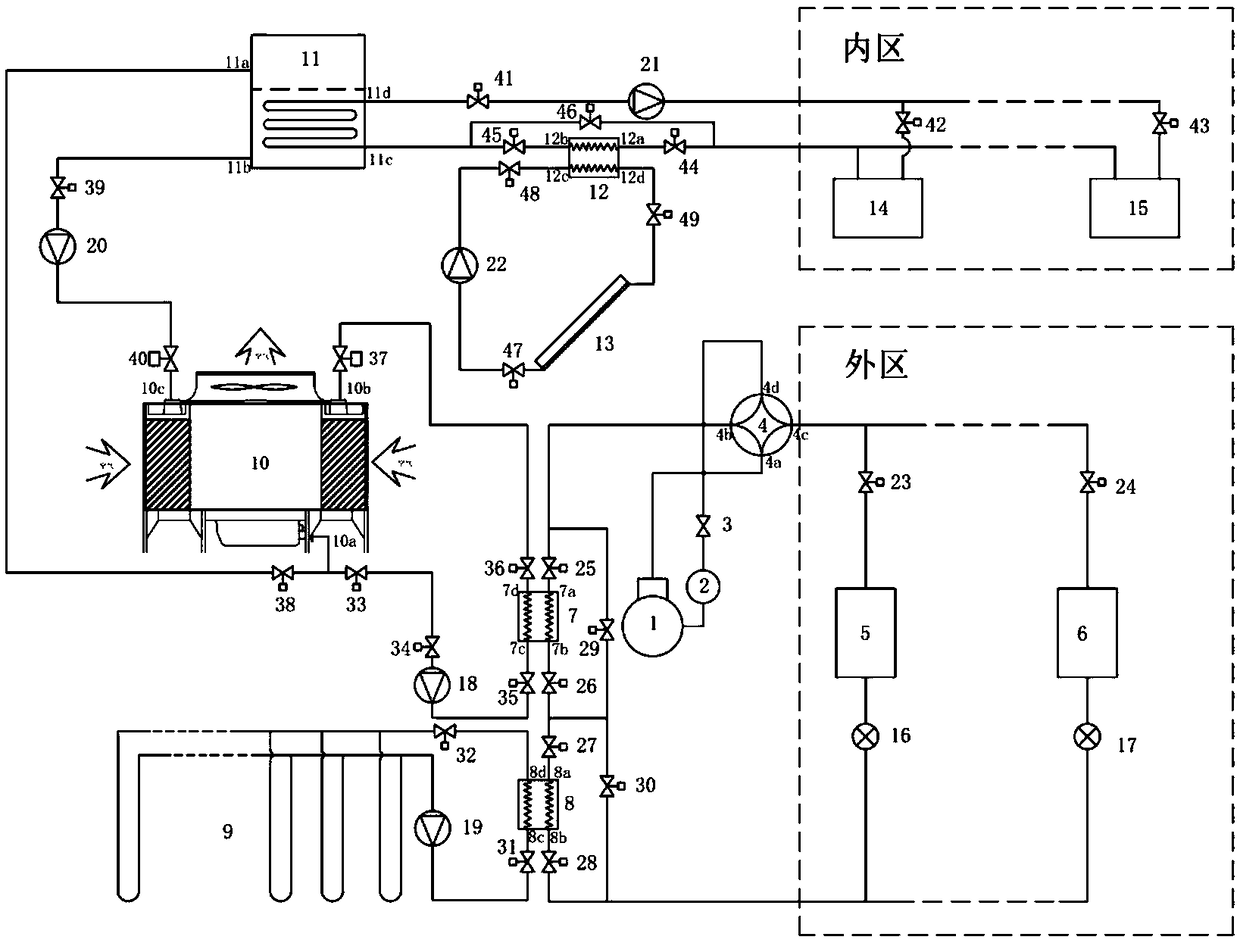

[0026]The invention includes a refrigerant circuit, a heat source tower circuit, a soil energy supply circuit, a solution regeneration circuit and a photothermal auxiliary regeneration circuit. Among them, the refrigerant circuit includes a compressor 1, an oil separator 2, a one-way valve 3, a four-way reversing valve 4, a first plate heat exchanger 7, a second plate heat exchanger 8, and a first indoor heat exchanger 5 , the second indoor heat exchanger 6, the first expansion valve 16, the second expansion valve 17, the first solenoid valve 23, the second solenoid valve 24, the third solenoid valve 25, the fourth solenoid valve 26, the fifth solenoid valve 27 , the sixth solenoid valve 28 , the seventh solenoid valve 29 , and the eighth solenoid valve 30 . In the refrigerant circuit, the output end of the compressor 1 is connected to the first input end 4a of the four-way reversing valve, and the first output end 4b of the four-way reversing valve is respectively connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com