A kind of marking composition, preparation method and application

A technology for marking and road marking, applied in the field of road materials, can solve problems such as affecting the service life of asphalt pavement, inability to judge the timing of high temperature or low temperature, and hidden dangers of high and low temperature diseases on asphalt pavement, so as to achieve stability and uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

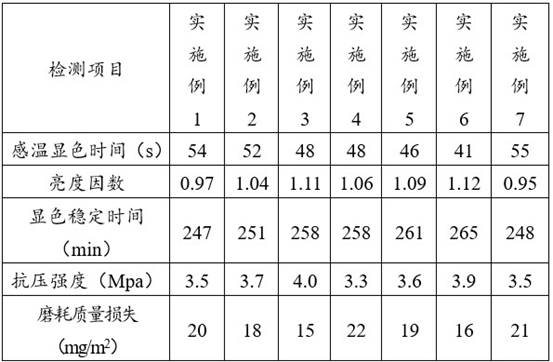

Embodiment 1

[0042]The marking composition prepared in this example, in parts by weight, includes 23 parts of heat-sensitive ink, 9 parts of thermally conductive silica gel, 16 parts of water-based acrylic resin, 8 parts of urea-formaldehyde resin, 26 parts of two-component marking paint, silicon carbide 16 parts of ceramic paint, 11 parts of transparent thermal insulation paint, 14 parts of neopentyl glycol diglycidyl ether.

[0043] The preparation method of the marking composition described in this embodiment comprises the following steps:

[0044] (1) Use marking spraying equipment to spray two-component marking paint on the surface of the road surface. After the surface is completely dry, lay thermal silica gel on the surface of the two-component marking paint;

[0045] (2) Apply an appropriate amount of binder water-based acrylic resin on the surface of the heat-conducting silica gel, use heat-sensitive ink to draw high-temperature warning or low-temperature warning words on the road...

Embodiment 2

[0048] The marking composition prepared in this embodiment, in parts by weight, includes 23 parts of heat-sensitive ink, 10 parts of thermally conductive silica gel, 18 parts of water-based acrylic resin, 9 parts of urea-formaldehyde resin, 28 parts of two-component marking paint, silicon carbide 18 parts of ceramic paint, 12 parts of transparent thermal insulation paint, 18 parts of neopentyl glycol diglycidyl ether.

[0049] The preparation method of the marking composition described in this embodiment comprises the following steps:

[0050] (1) Use marking spraying equipment to spray two-component marking paint on the surface of the road surface. After the surface is completely dry, lay thermal silica gel on the surface of the two-component marking paint;

[0051] (2) Apply an appropriate amount of binder water-based acrylic resin on the surface of the heat-conducting silica gel, use heat-sensitive ink to draw high-temperature warning or low-temperature warning words on the...

Embodiment 3

[0054] The marking composition prepared in this embodiment, in parts by weight, includes 24 parts of heat-sensitive ink, 12 parts of thermally conductive silica gel, 20 parts of water-based acrylic resin, 10 parts of urea-formaldehyde resin, 30 parts of two-component marking paint, silicon carbide 20 parts of ceramic paint, 14 parts of transparent thermal insulation paint, 20 parts of neopentyl glycol diglycidyl ether.

[0055] The preparation method of the marking composition described in this embodiment comprises the following steps:

[0056] (1) Use marking spraying equipment to spray two-component marking paint on the surface of the road surface. After the surface is completely dry, lay thermal silica gel on the surface of the two-component marking paint;

[0057] (2) Apply an appropriate amount of binder water-based acrylic resin on the surface of the heat-conducting silica gel, use heat-sensitive ink to draw high-temperature warning or low-temperature warning words on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com