Method for deacidifying paper by electro-adsorption

An electric adsorption and paper technology, applied in the post-processing of waste paper, etc., can solve the problems of low efficiency and small processing capacity, and achieve the effects of reducing negative impact, low cost, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Soak the non-woven mat with deionized water, then spread the soaked mat on the anode plate, and the anode plate is covered with activated carbon fiber cloth (thick 1.5mm, BET: 1000m 2 / g);

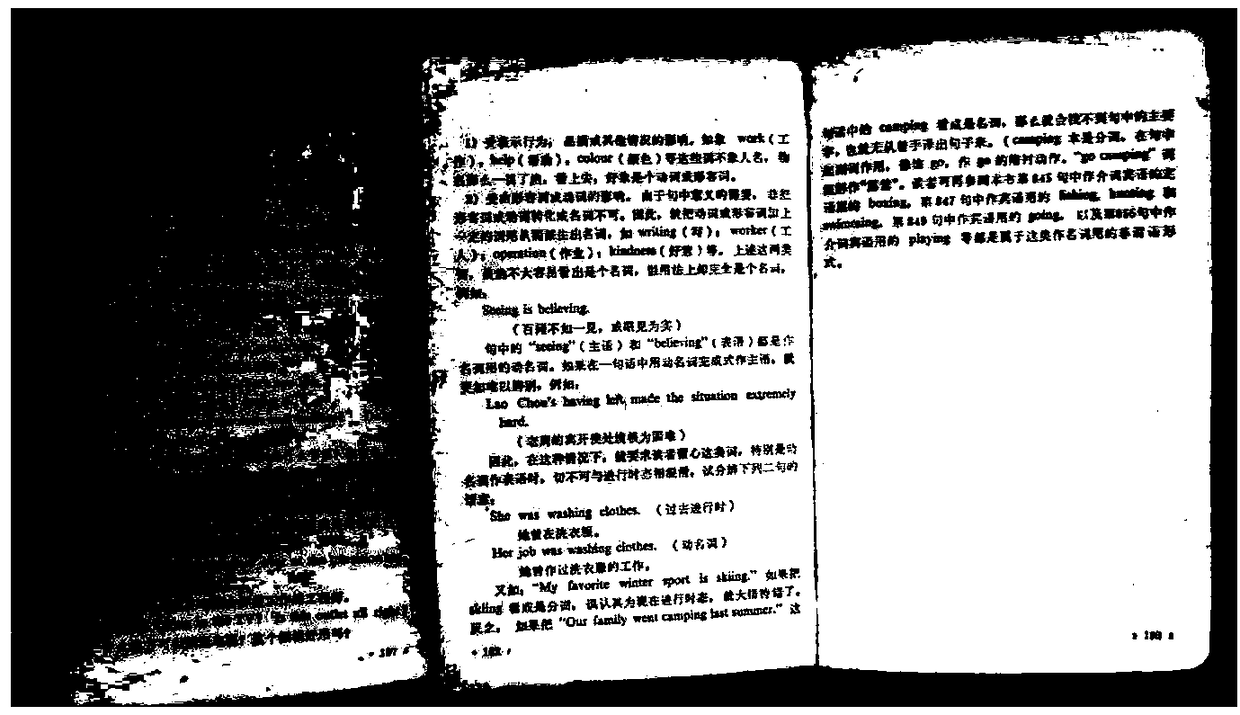

[0040] Lay the single-page paper to be processed (one page of the "English Nine Hundred Sentences Chinese Translation Notes" printed by Beijing Commercial Press in 1978; 16K, offset paper printing) on the above-mentioned pad, and place the flat graphite cathode plate Press it and clamp the two plates together;

[0041] Connect the two polar plates to regulated direct current, the voltage is 1.5V, and the electrosorption time is 5 minutes; then cut off the power supply, remove the pad, and let the paper air dry naturally. The situation comparison before and after paper deacidification is shown in Table 1 and figure 1 , figure 1 It is a comparison chart of paper before and after deacidification in Example 1. figure 1 In the middle, the right side is the paper before deacidificat...

Embodiment 2

[0046] Soak the non-woven mat with deionized water, then spread the soaked mat on the anode plate, and the anode plate is covered with activated carbon fiber cloth (thick 1.5mm, BET: 1000m 2 / g);

[0047] Spread the single-page paper to be processed (one page of the "Rhetoric Outline" printed by Shanghai New Knowledge Publishing House in 1957; 16K, offset paper printing) on the above-mentioned pad, press the flat graphite cathode plate, and Clamp the two plates together;

[0048] Connect the two polar plates to regulated direct current, the voltage is 1.5V, and the electrosorption time is 5 minutes; then cut off the power supply, remove the pad, and let the paper air dry naturally. The situation comparison before and after paper deacidification is shown in Table 2 and figure 2 , figure 2 It is a comparison chart of paper before and after deacidification in Example 2. figure 2 In the middle, the right side is the paper before deacidification, and the left side is the p...

Embodiment 3

[0053] Soak the non-woven mat with deionized water, then spread the soaked mat on the anode plate, and the anode plate is covered with activated carbon fiber cloth (thick 1.5mm, BET: 1000m 2 / g);

[0054] Lay the multi-page paper to be processed (three pages of the "English Nine Hundred Sentences Chinese Translation Annotation" printed by Beijing Commercial Press in 1978; 16K, offset paper printing) on the above-mentioned cushion layer, and place the flat graphite cathode plate Press it and clamp the two plates together;

[0055] Connect the two polar plates to regulated direct current, the voltage is 1.5V, and the electrosorption time is 8 minutes; then cut off the power supply, remove the pad, and let the paper air dry naturally. See Table 3 for the comparison of paper before and after deacidification.

[0056] Table 3 Example 3 Comparison table of analytical indicators before and after paper deacidification

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com