Quicklime circulating fluidized bed grading dry digestion system

A circulating fluidized bed and digestion system technology, applied in the field of dry digestion system, can solve the problems that slaked lime cannot meet the requirements of fluffy dry powder, insufficient digestion of quicklime, and high quality requirements of imported quicklime, so as to improve digestibility and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

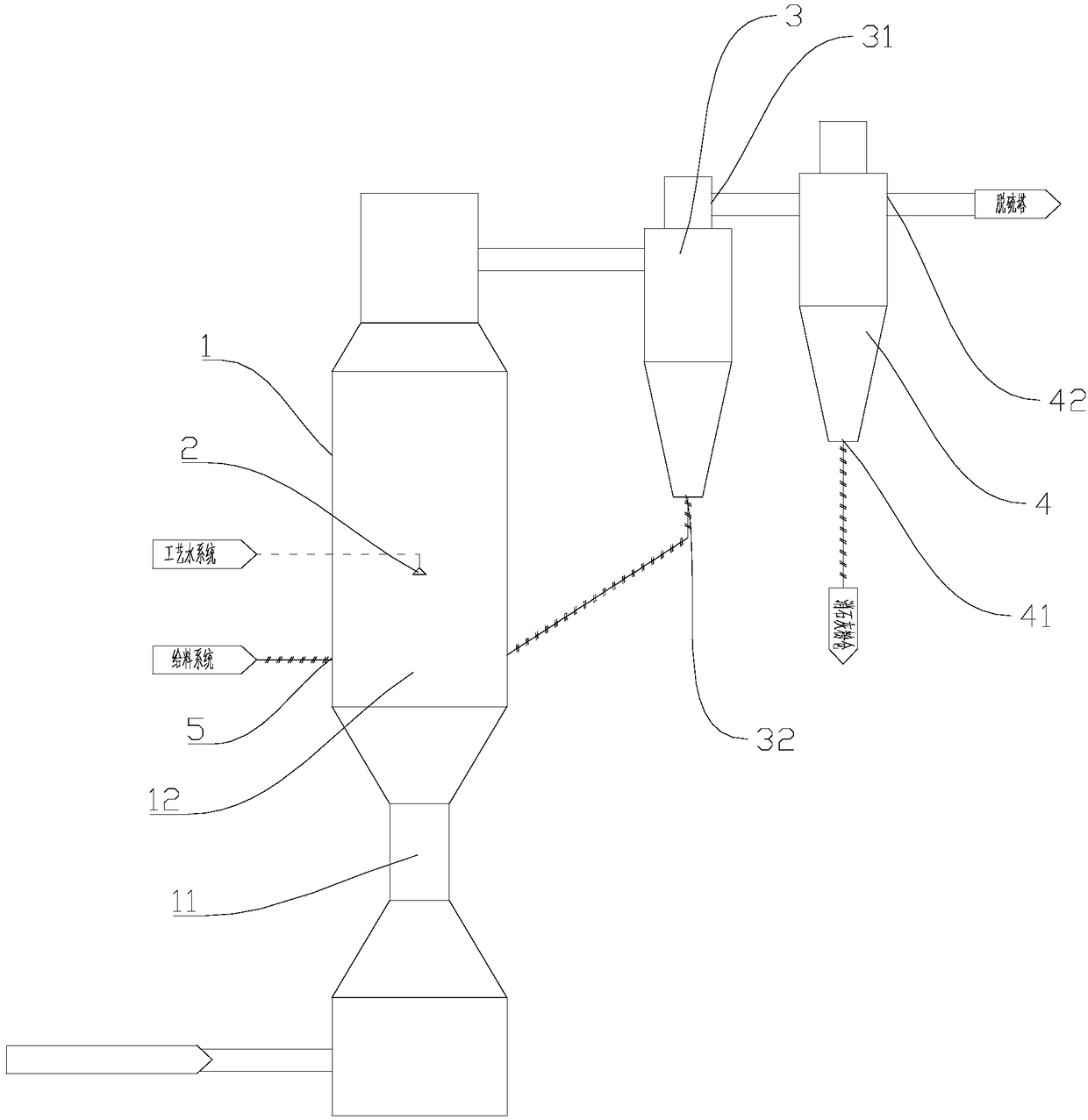

[0018] Example: a quicklime circulating fluidized bed graded dry digestion system, the structure is as follows figure 1 As shown, it includes a digestion tower 1. The digestion tower 1 includes a venturi 11. The digestion tower 1 is located at the upper part of the venturi 11 and is connected with a feeding system for providing quicklime raw materials. The lower part of the venturi 11 is connected with a desulfurization tower for providing high-temperature flue gas. , and a fluidized bed area 12 is formed above the Venturi 11, that is, quicklime enters the fluidized bed area 12 and is fluidized by high-temperature flue gas. The quicklime in the bed zone 12 provides moisture to react to generate slaked lime.

[0019] The digestion tower 1 is located above the water supply device and is connected with a separation device. The separation device includes a primary cyclone separator 3 and a secondary cyclone separator 4. The inlet of the primary cyclone separator 3 is connected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com