Natural gas tank installing fixing frame

A technology of natural gas and fixed frame, applied in packaging, external frame, transportation and packaging, etc., can solve the problems of large manual labor, low efficiency, poor effect, etc., and achieve the effect of good effect, convenient installation and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

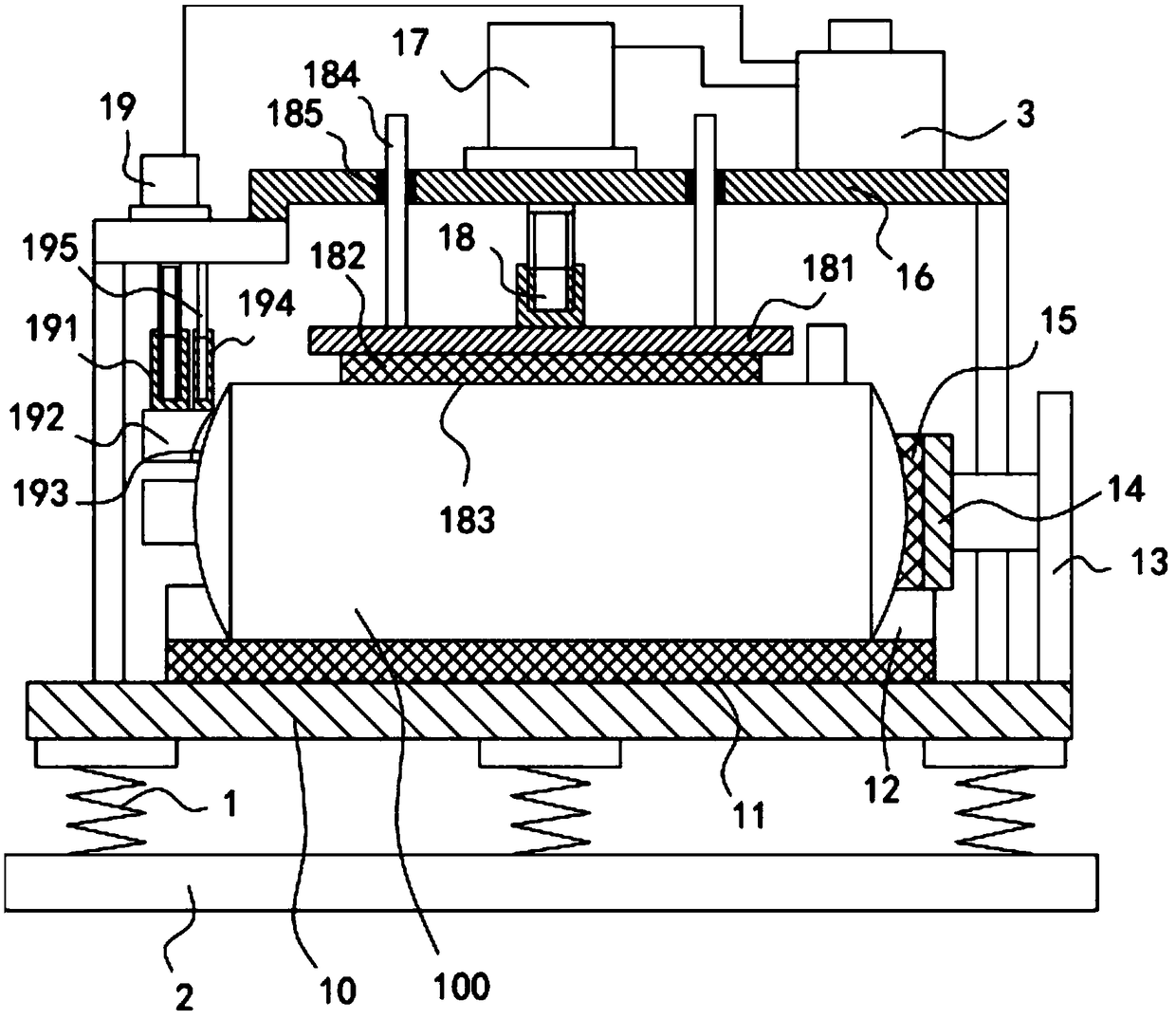

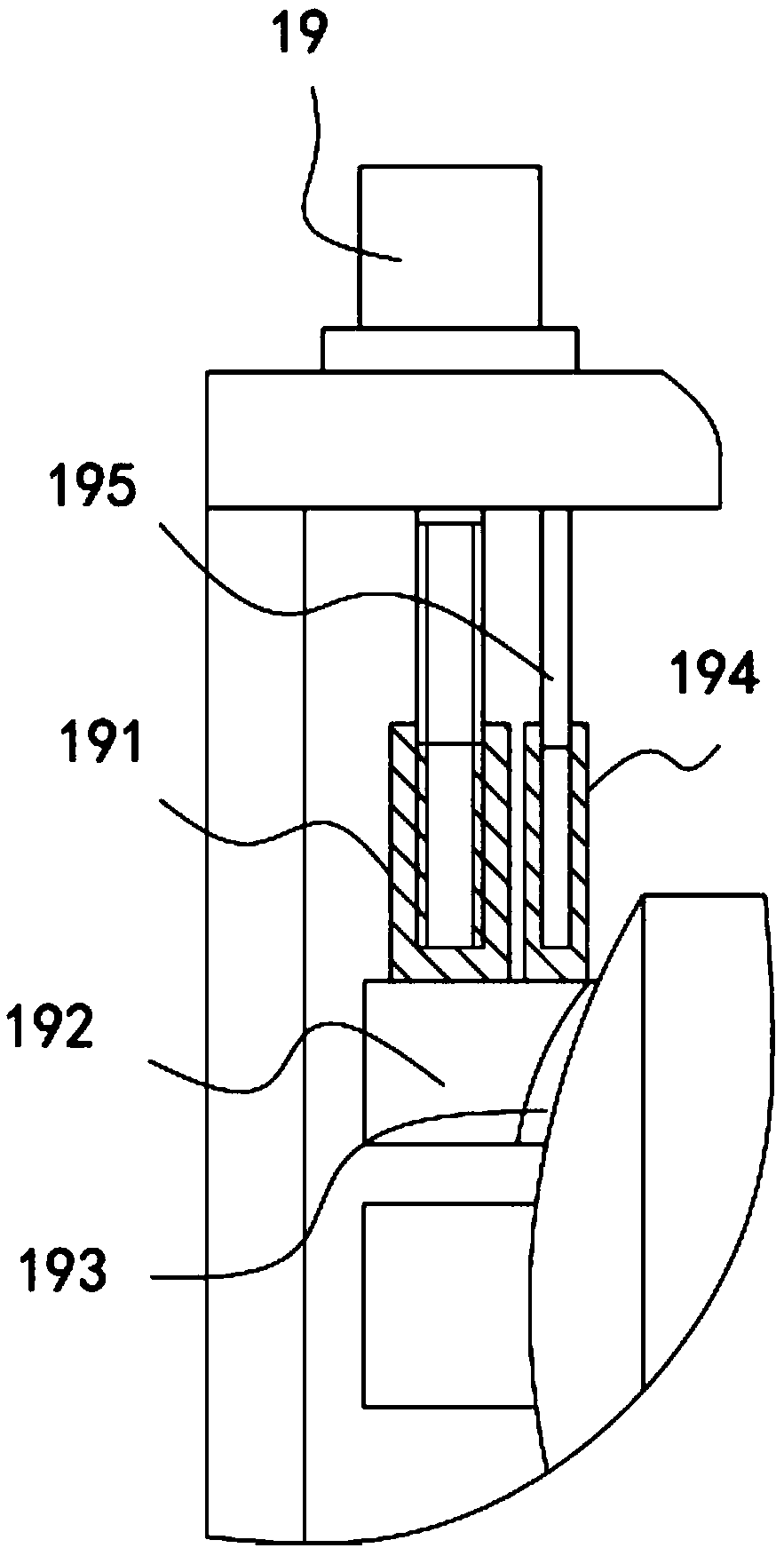

[0016] Example: see Figure 1 to Figure 2 As shown, a natural gas tank installation fixture includes a main bottom plate 10, an elastic main fixing block 11 is fixed in the middle of the top surface of the main bottom plate 10, and an arc-shaped groove 12 is placed in the middle of the top surface of the elastic main fixing block 11. The right side top surface of the main floor 10 is fixed with a right support plate 13, the left side of the right support plate 13 is provided with a right limiting plate 14, and the left side wall of the right limiting plate 14 is fixed with an elastic end plate 15. The tank body 100 is inserted into the placement arc-shaped groove 12 and pressed against the bottom surface of the placement arc-shaped groove 12, the elastic end plate 15 is pressed against the right end surface of the natural gas tank body 100, and the top surface of the main bottom plate 10 is fixed with Upper support frame 16, the upper clamping motor 17 that is fixed on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com