Device and method for on-line dynamic measurement of geometric parameters of wheels of train

A technology of train wheels and geometric parameters, applied in the direction of rim measurement/measurement, etc., can solve the problems of distortion, rim vertex circle diameter deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

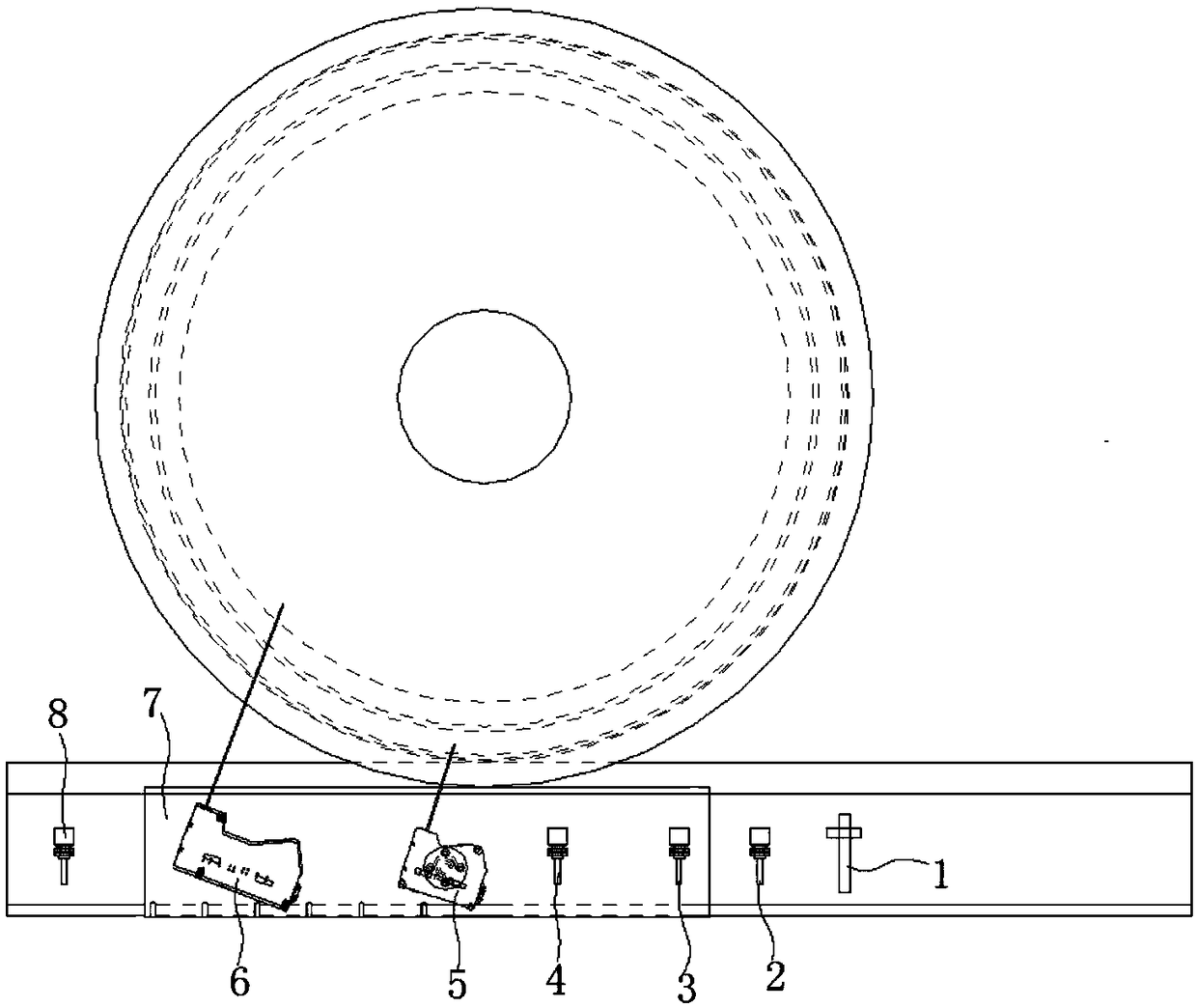

[0081] Such as figure 1 As shown, a kind of device for online dynamic measurement of the geometric parameters of train wheels in this embodiment includes a speed measuring sensor 1, a start switch 2, an eddy current displacement sensor 13, an eddy current displacement sensor 1 arranged on the inner side of the track along the direction of train travel. Sensor II 4, laser displacement sensor I 5, laser displacement sensor II 6, and stop switch 8, wherein the detection beam of laser displacement sensor I 5 is perpendicular to the inner rim surface of the wheel, and there is an angle α between it and the top surface of the track. The detection beam of the displacement sensor II 6 is perpendicular to the inner rim surface of the wheel, and there is an angle β with the top surface of the track; the line connecting the centers of the eddy current displacement sensor I3 and the center of the eddy current displacement sensor II4 is parallel to the top surface of the track. Both the ed...

Embodiment 2

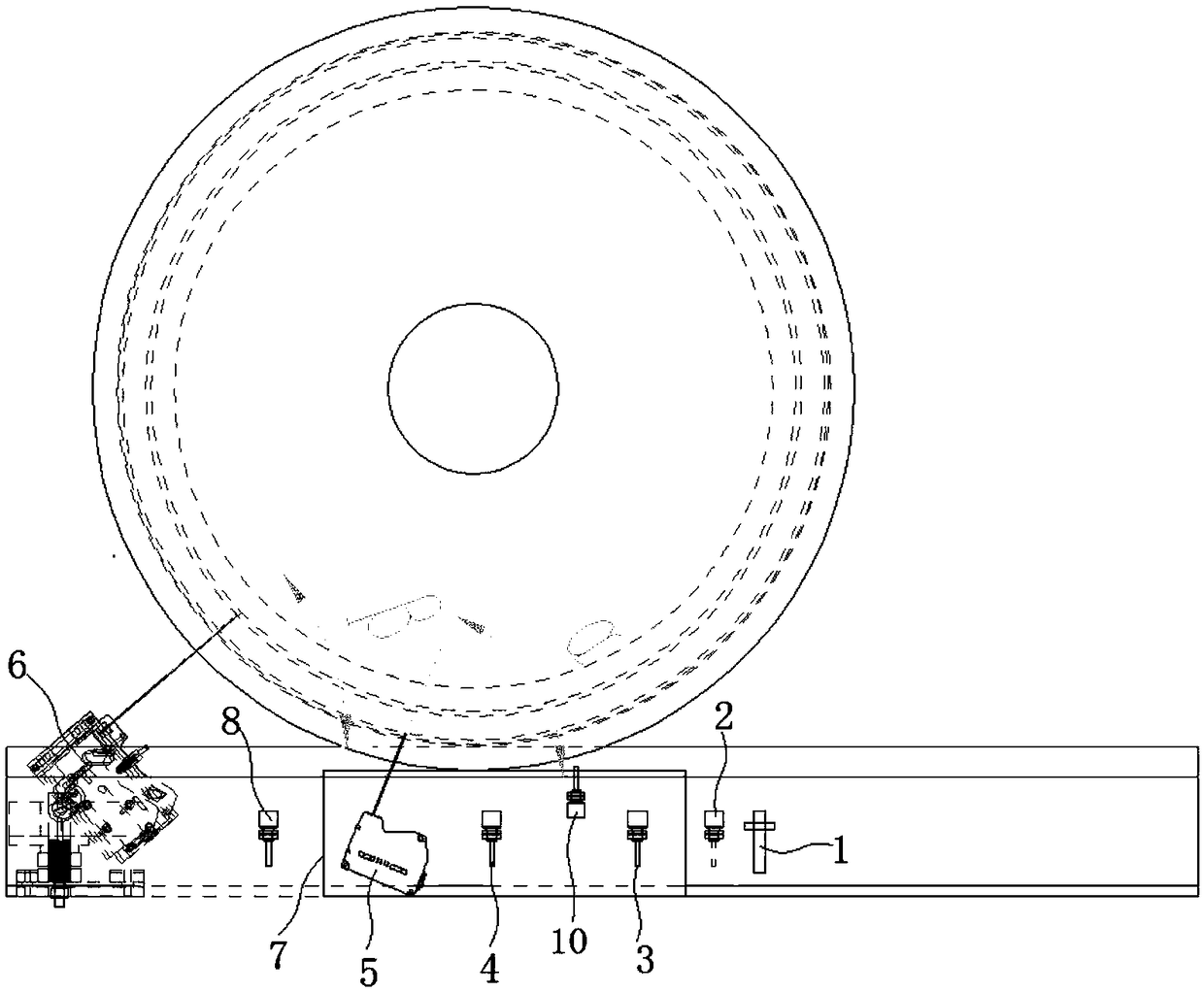

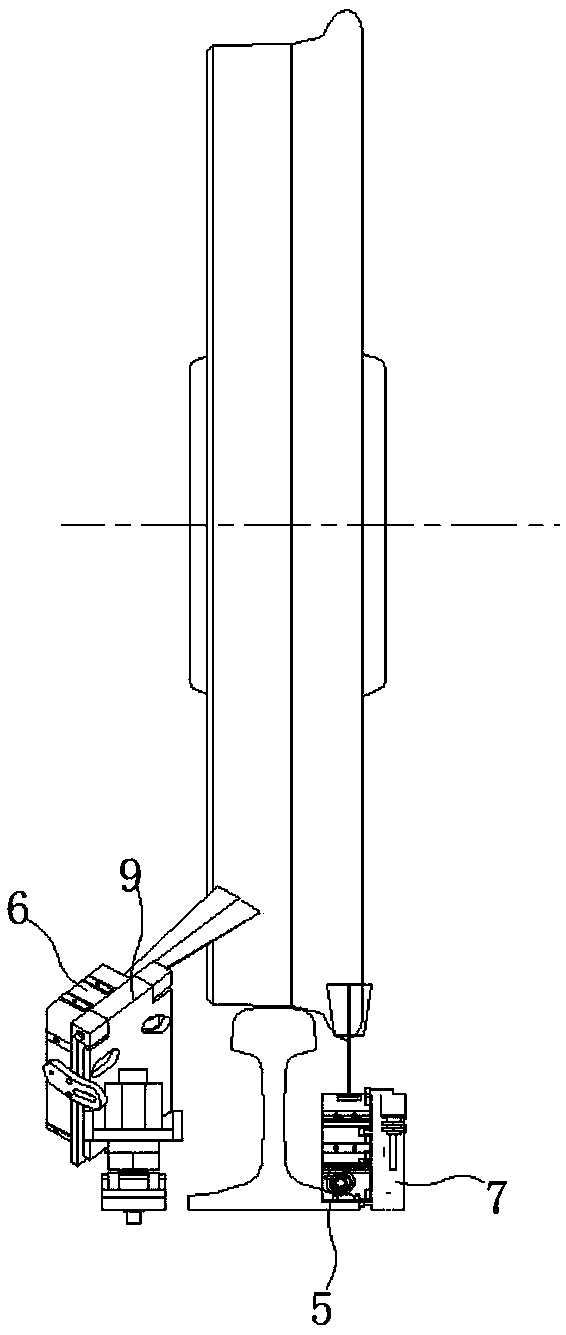

[0105] Such as Figure 2-4As shown, a device for online dynamic measurement of the geometric parameters of train wheels in this embodiment has a structure basically the same as in Embodiment 1, the difference mainly being that in this embodiment, the laser displacement sensor II6 is installed on the track through the second bracket 9 The outer side, and there is an inclined angle β between the detection beam and the top surface of the track, and an inclined angle γ between the inner rim surface of the wheel; a displacement sensor III 10 is also installed on the first bracket 7, and a displacement sensor III 10 It is used to measure the amount of depression when the first bracket 7 is pressed down by the wheel rim, and its sampling frequency is the same as that of the two laser displacement sensors, and the displacement sensor III 10 is connected to the control system and the data processing system.

[0106] combine Figure 2-Figure 5 , a method for online dynamic measurement ...

Embodiment 3

[0133] The structure and measurement method of the measuring device in this embodiment are the same as those in Embodiment 1 or 2, the main difference being that the distance d between the wheel diameter measurement base point and the inner rim surface of the wheel in this embodiment is 70mm.

[0134] Example 3

[0135] The structure of the measuring device and the measuring method in this embodiment are the same as in Embodiment 1 or 2, the difference mainly lies in: the diameter D corresponding to the base point of measuring the thickness of the rim in this embodiment h =D T +20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com