Vibration measurement equipment for rail and measurement system using same

A technology of vibration measurement and rail, applied in the field of measurement system, to achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

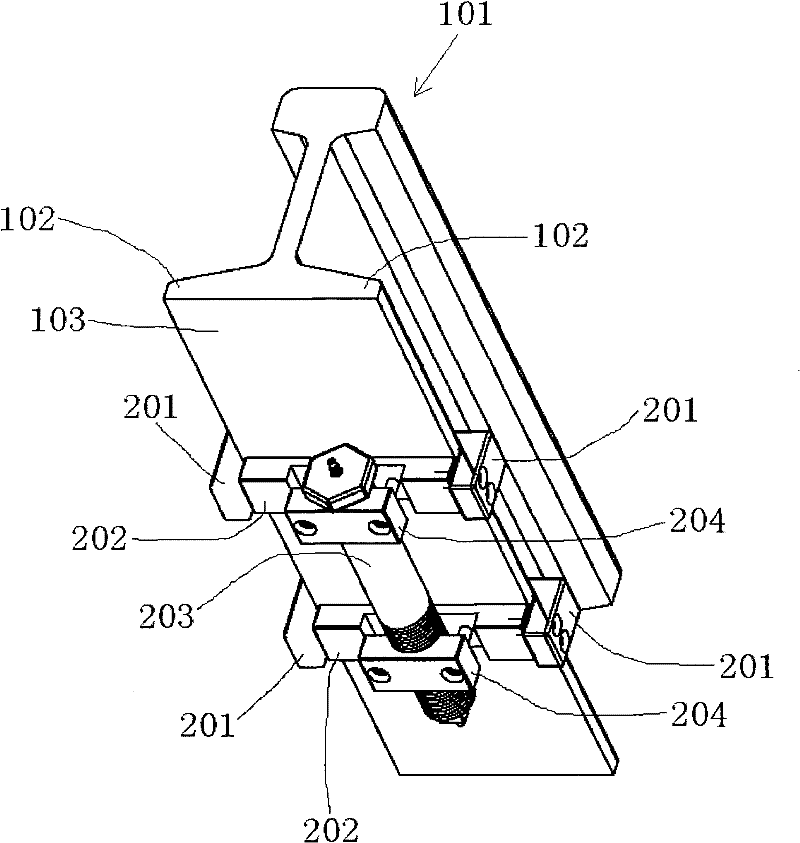

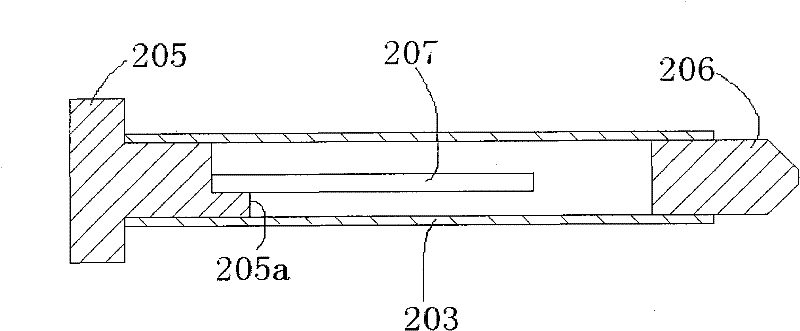

[0015] figure 1 and figure 2 A first embodiment of the vibration measuring device for railroad rails of the present invention is shown. figure 1 It is a schematic diagram of the three-dimensional structure of the first embodiment of the rail vibration measuring device of the present invention; figure 2 yes figure 1 Schematic diagram of the structure of the protection tube of the vibration measurement equipment for railway rails shown.

[0016] Such as figure 1 As shown, the vibration measurement equipment for rail includes a protection tube 203 with a vibration sensor 207 installed inside and two sets of claw fixing components located at both ends of the protection tube 203 .

[0017] Such as figure 1 As shown, the protection tube 203 is fixedly installed on the bottom 103 of the rail 101 through two sets of claw fixing components, and is substantially parallel to the longitudinal direction of the rail 101 . It should be noted that the protection tube 203 can also be a...

no. 2 example

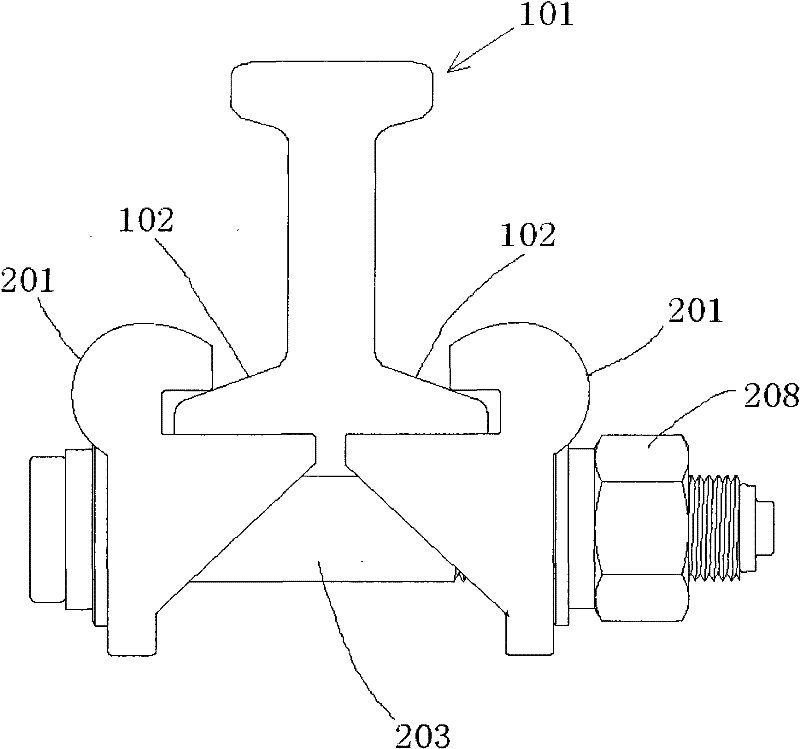

[0024] image 3 A schematic structural view showing a second embodiment of the rail vibration measuring device of the present invention.

[0025] Such as image 3 As shown, the protective tube 203 is fixed substantially parallel to the transverse direction of the rail 101 . It should be noted that the protective pipe 203 may also form an inclined angle with the transverse direction of the rail 101 .

[0026] Such as image 3 As shown, a pair of holding claws 201, 201 are respectively grasped on the flanges 102 on both sides of the lower part of the rail 101, and the pair of holding claws 201, 201 are transversely opposite to each other. Two ends of the protection tube 203 are respectively supported and fixed on a pair of claws 201 , 201 . Preferably, the protection tube 203 is fastened to the pair of claws 201 , 201 by using a lock nut 208 provided at one end of the protection tube 203 .

[0027] In this embodiment, the holding claw device only includes a pair of holding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com