Straddle type single-rail track beam formwork system and application method

A straddle-type monorail and track beam technology, which is applied in the field of rail transportation, can solve the problems of track beam quality and construction safety risks, difficulty in meeting the millimeter-level high precision of PC track beams, PC track beam adjustment, etc., and achieve mold-reversing efficiency High, simple structure, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

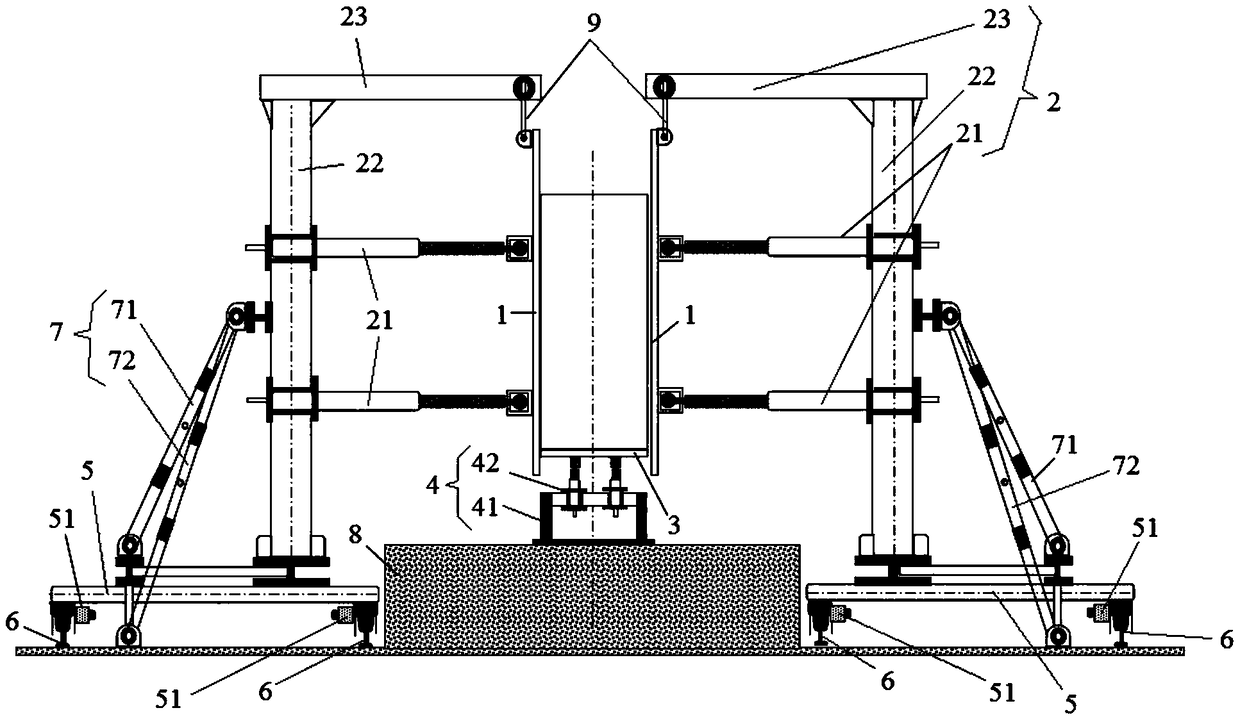

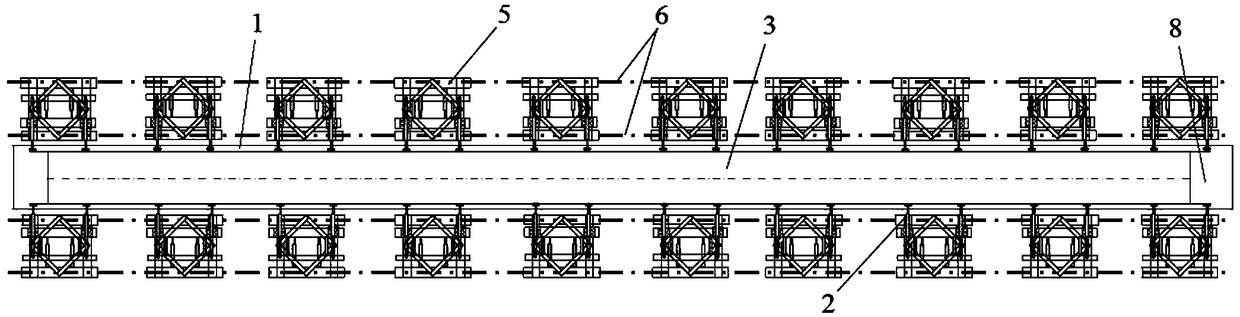

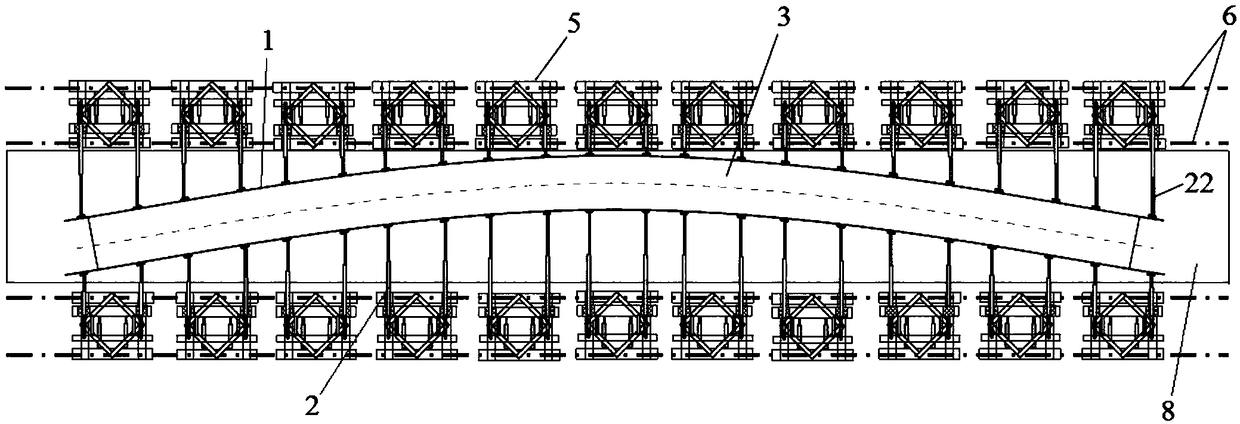

[0043] Such as Figure 1-4 As shown, a formwork system of a straddle type monorail track beam according to the present invention includes:

[0044] The side form 1 includes a side form panel and a top plate linear adjustment assembly, the side form panel is used for forming the side wall of the track beam, and the top plate linear adjustment assembly is arranged above the inner side of the side form panel for adjusting the top plate in the the alignment of the side-form panels;

[0045] The function of the side form panel is to ensure the geometric dimensions of the track beam section, which is composed of a whole steel plate, and the embedded parts on the track beam are determined according to the final position of the embedded parts to open positioning connection holes on the side form panel; The bottom of the top plate alignment adjustment assembly is a triangular structure. By adjusting the height of the top plate alignment plate, the beam height, vertical curve alignment...

Embodiment 2

[0057] Such as Figure 1-4 As shown, the method for using a formwork system of a straddle-type monorail track beam according to the present invention, applying the formwork system of a straddle-type monorail track beam as described in Embodiment 1, comprises the following steps:

[0058] A. Set the bottom form force mechanism 4 at the position to be poured, the bottom form force mechanism 4 is connected to the bottom form 3, adjust the bottom form force mechanism 4 so that the bottom form 3 forms the shape of the designed track beam bottom ;

[0059] B. Control the driving assembly 51 to drive the mobile platform 5 to move along the track 6 to the position to be poured;

[0060] C. Adjust the position of each traversing assembly 22 in the chute according to the design of the track beam and fix it, then adjust all the traversing assemblies 22 to pull and compress the side mold 1, and constrain the side mold 1 to form the required shape , all the traversing components 22 synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com