Flexible clamping jaw

A gripper and flexible technology, applied in the field of flexible grippers, can solve the problems of inability to meet the adaptive grasping of objects of different shapes and sizes, reduce production efficiency and income, damage the surface of items, etc., to achieve a wide range of applications and increase production efficiency. And the effect of high income and high grasping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

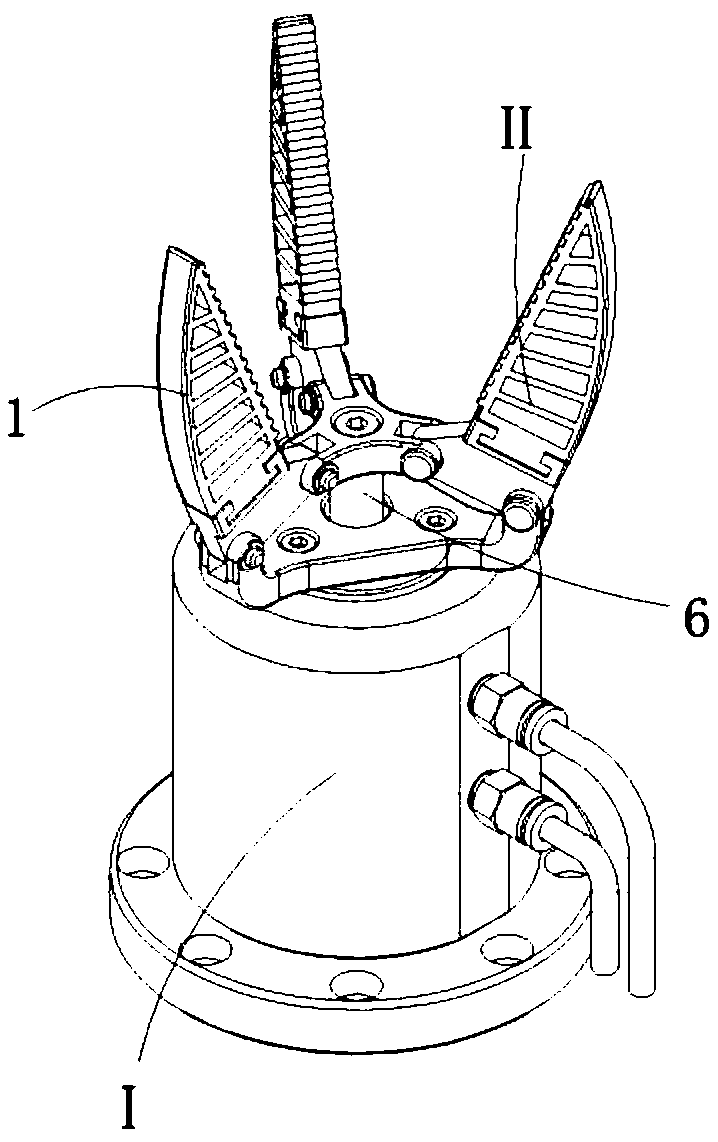

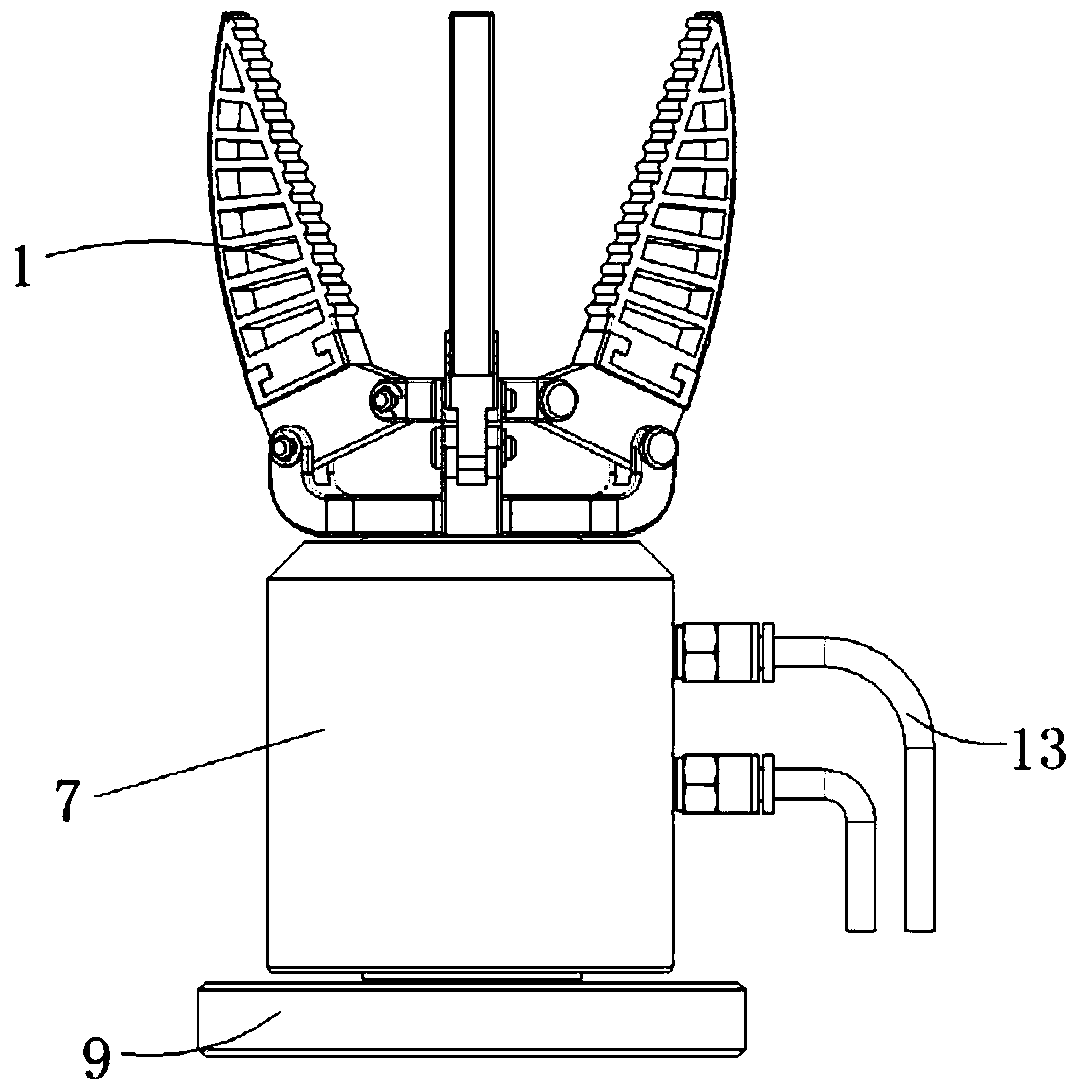

[0026] Examples, see attached Figure 1~6 , a flexible jaw, including a cylinder driving mechanism I and a jaw assembly II movably mounted on the cylinder driving mechanism; the cylinder driving mechanism includes a cylinder 5 and a cylinder rotatably mounted on the periphery The air guide ring 7, the bottom of the cylinder block is connected with a fixed base plate 9, the fixed base plate 9 is a cylindrical plate, and the circumference of the cylindrical plate is provided with eight groups of mounting holes 901, through which the mounting holes can be fixed by using bolts. The base plate is fixed on the main shaft of the lathe or the moving working platform. When the main shaft of the lathe or the moving working platform rotates, the fixed bottom plate will drive the cylinder body to rotate infinitely at 360°, but the air guide ring will not rotate with it, and the air intake pipe or oil pipe installed on the air guide ring will always remain original. status.

[0027] A pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com